Discover how a Manufacturing Execution System (MES) transforms factory operations. This complete guide explains MES features, benefits, and how it connects real-time production with enterprise planning for smarter manufacturing decisions.

Understanding Manufacturing Execution Systems (MES):The Foundation of Smart Manufacturing

In today’s rapidly evolving industrial world, efficiency, precision, and real-time data tracking are non-negotiable. As someone who has been deeply immersed in smart manufacturing trends, I can confidently say that Manufacturing Execution Systems (MES) have become the backbone of modern production facilities. If a factory were a well-rehearsed orchestra, MES would be the conductor, ensuring that every instrument, machines, workflows, and human operators, plays in perfect harmony.

For businesses striving to optimize their operations, reduce waste, and enhance production efficiency, implementing an MES isn’t just an option, it’s a necessity. But what exactly is an MES, and why has it become a game changer in smart manufacturing? Let’s break it down.

What is a Manufacturing Execution System? A Simple Yet Comprehensive Explanation

At its core, a Manufacturing Execution System (MES) is a software solution that provides real-time monitoring, control, and execution of manufacturing processes. I like to think of it as the nervous system of a factory, it constantly gathers data, processes information, and ensures that production flows smoothly and efficiently.

Breaking Down the Core Functions and Purpose of MES

According to MES expert opinions, a well-implemented MES bridges the gap between high-level business planning (ERP) and real-time factory execution. Here’s what it does:

✅ Production Scheduling & Monitoring – Keeps production on track and adapts to real-time changes.

✅ Real-Time Data Collection & Analysis – Captures key production metrics to improve efficiency.

✅ Quality Control & Compliance – Ensures every product meets industry standards.

✅ Inventory & Resource Management – Optimizes material usage and prevents shortages.

✅ Workforce Management – Assigns tasks efficiently and monitors performance.

In short, MES is the missing puzzle piece that transforms traditional manufacturing into a data-driven, smart factory.

The Relationship Between MES, ERP, and SCADA: How They Work Together

To fully appreciate MES, we need to understand how it interacts with ERP (Enterprise Resource Planning) and SCADA (Supervisory Control and Data Acquisition).

- ERP acts as the brain of a company, managing high-level business operations such as finance, supply chain, and procurement.

- SCADA functions as the hands, directly controls and monitors real-time manufacturing operations.

- MES is the spinal cord, connecting ERP’s strategic planning with SCADA’s real-time execution, ensuring everything runs smoothly without bottlenecks.

I’ve seen factories struggle because their systems weren’t connected properly, production delays, excessive waste, and machine breakdowns. But with a properly integrated MES, everything moves seamlessly from planning to execution.

The Evolution of MES: From Traditional Manufacturing to Industry 4.0

The manufacturing industry has undergone a dramatic transformation over the past few decades. Gone are the days of manual record-keeping and paper-based workflows, today, factories are shifting towards fully digital, real-time operations.

Early MES Systems vs. Modern Cloud-Based MES

Back in the day, MES solutions were rigid, on-premise systems that required massive hardware investments. They mainly tracked production output but lacked real-time analytics and predictive insights.

Fast forward to today, and MES has evolved into a cloud-based, AI-driven system with:

✅ Real-time visibility across global production sites

✅ AI-powered predictive analytics to optimize efficiency

✅ Integration with IoT devices, smart sensors, and robotics

✅ Scalability for businesses of all sizes

I’ve personally witnessed manufacturers slash production downtime and increase output just by upgrading to a cloud-based MES with real-time monitoring.

The Transition from Manual Processes to Real-Time Digital Manufacturing

One of the biggest shifts I’ve seen in modern manufacturing is the move from reactive to proactive decision-making.

Take predictive maintenance, for example. In the past, factories waited until machines broke down before repairing them, leading to costly downtime. Now, with MES integrated with IoT sensors, machines can detect issues before they happen, allowing for preventive action and maximum uptime.

Another game-changer? Remote factory management. With real-time MES dashboards, plant managers can now monitor and control production from anywhere, a feature that has become invaluable in today’s increasingly globalized and remote-friendly work environments.

From firsthand experience, implementing an MES isn’t just about improving efficiency, it’s about future-proofing your business.

We’re in an era where speed, precision, and data-driven decision-making define success in manufacturing. Companies that embrace cloud-based MES, AI, and real-time analytics gain a significant competitive edge, while those who cling to outdated manual processes risk falling behind.

Why Choosing the Right MES Matters: The Foundation of Smart Manufacturing

As someone who has worked with manufacturing optimization and seen factories struggle with inefficiencies, I can confidently say this: choosing the right Manufacturing Execution System (MES) is one of the most crucial decisions a manufacturer can make.

A well-implemented MES isn’t just a tool, it’s the backbone of smart manufacturing. It directly impacts efficiency, quality control, cost savings, and overall competitiveness. In contrast, a poorly chosen MES can become a bottleneck, creating more problems than solutions.

Let’s dive into why MES selection matters and what manufacturers need to consider to maximize its value.

What is a Manufacturing Execution System (MES) and Why Does It Matter?

A Manufacturing Execution System (MES) is a software platform that enables real-time monitoring, control, and optimization of manufacturing operations. I often describe it as the connective tissue between a company’s business strategy (ERP) and actual production execution (shop floor operations).

The Role of MES in Modern Manufacturing

Manufacturers today face increasing pressure to produce faster, cheaper, and with higher precision. This is where MES plays a game-changing role:

✅ Enhances Production Efficiency – Reduces downtime and optimizes production schedules.

✅ Improves Product Quality – Ensures compliance with standards and reduces defects.

✅ Increases Traceability – Tracks materials, processes, and output for complete visibility.

✅ Reduces Waste – Identifies inefficiencies and minimizes excess raw material usage.

In today’s competitive industrial world, an MES isn’t a nice-to-have, it’s a must-have.

How MES Bridges the Gap Between ERP and the Shop Floor

If ERP (Enterprise Resource Planning) is the brain of an organization, and the shop floor is its muscles, then MES is the nervous system, ensuring that commands are executed smoothly and in real time.

- ERP handles high-level business processes: supply chain, finance, and HR.

- The shop floor is where actual production happens: machines, operators, and logistics.

- MES connects the two, ensuring that high-level strategies translate into real-time execution without bottlenecks.

Without an MES, it’s like running a company with a brilliant strategy but no way to execute it effectively.

The Business Impact of an MES: Cost Savings, Efficiency, and ROI

Implementing the right MES can transform a factory from a slow, inefficient operation into a highly optimized, cost-effective powerhouse.

How MES Reduces Waste and Improves Productivity

I’ve seen manufacturers slash waste by over 20% just by implementing an MES that optimizes raw material usage. Here’s how MES boosts efficiency:

✅ Minimizes Production Delays – Real-time data helps identify bottlenecks before they cause downtime.

✅ Reduces Defective Products – Automated quality control minimizes human error.

✅ Optimizes Resource Allocation – Ensures machines and labor are used efficiently.

For industries where precision and speed are everything, like automotive, pharmaceuticals, and electronics, MES can be a game-changer profitability.

The Real Financial Benefits of MES Implementation

Beyond efficiency, MES delivers a measurable return on investment (ROI) by cutting costs and increasing production output.

💰 Lower Labor Costs – Automation reduces the need for manual data entry and reporting.

⚙️ Fewer Equipment Failures – Predictive maintenance prevents costly machine breakdowns.

📉 Reduced Inventory Costs – MES tracks material usage to avoid overstocking or shortages.

Manufacturers who adopt cloud-based MES see even higher ROI since they eliminate costly on-premise IT infrastructure while gaining real-time data accessibility from anywhere.

The Risks of Choosing the Wrong MES: Common Pitfalls to Avoid

I’ve seen companies rush into MES adoption without fully understanding their needs, only to end up with a system that creates more inefficiencies than it solves.

How an Ill-Fitted MES Can Lead to Inefficiencies

When a company chooses the wrong MES, the consequences can be devastating:

❌ Poor Integration – The MES doesn’t communicate well with ERP or shop floor systems, leading to data silos.

❌ Limited Scalability – A system that works today might not support future growth.

❌ User Complexity – If the MES is too complicated, operators won’t use it effectively, leading to manual workarounds.

Instead of streamlining operations, a bad MES can slow things down, create workflow confusion, and even increase costs due to excessive customization or workarounds.

Common Mistakes Manufacturers Make When Selecting an MES

To avoid these pitfalls, manufacturers must choose an MES that aligns with their specific business needs. Some of the most common mistakes I’ve seen include:

🚫 Focusing Only on Cost – The cheapest option may lack the scalability and features needed for long-term success.

🚫 Not Considering User Experience – If factory operators struggle to use the system, adoption rates will be low.

🚫 Ignoring Vendor Support – A lack of technical support and updates can render an MES outdated quickly.

The best MES implementations come from carefully evaluating long-term business needs, ensuring seamless integration with existing systems, and choosing a vendor that offers strong support and updates.

Choosing the right MES can make or break a manufacturer’s operational success.

A well-selected MES reduces waste, boosts efficiency, and delivers strong ROI, but a poorly chosen MES can introduce inefficiencies, increase costs, and disrupt production.

Key Factors to Consider When Choosing the Best MES for Your Business

Having worked in the manufacturing industry for years, I’ve seen firsthand how a well-chosen Manufacturing Execution System (MES) can transform operations, and how a poorly selected one can cause more problems than it solves. The difference between a seamless, efficient production process and a chaotic, data-siloed mess often comes down to choosing the right MES.

Many companies approach MES selection like buying software, they look for features, compare vendors, and sign a contract. But in reality, MES is not just software, it’s the operational backbone of modern manufacturing. A good MES should align with business goals, integrate with existing systems, and scale as production grows.

Based on Major MES experts’ experience implementing and optimizing MES solutions, here are the key factors every manufacturer should consider before making a decision.

Industry-Specific MES: Why One Size Does Not Fit All

One of the biggest mistakes I’ve seen companies make is assuming all MES solutions are the same. In reality, manufacturing in automotive, pharmaceuticals, food production, and discrete manufacturing all have unique requirements. An MES that works well for an automobile assembly line may not be the best fit for a pharmaceutical batch process.

MES Requirements for Different Industries

Different industries demand different MES capabilities:

- 🚗 Automotive Manufacturing – Requires real-time tracking of parts, assembly processes, and rigorous defect detection to comply with industry standards like IATF 16949.

- 💊 Pharmaceutical Manufacturing – Needs batch tracking, compliance with FDA 21 CFR Part 11, and electronic batch records (EBR) to ensure regulatory compliance.

- 🍔 Food & Beverage – Must support recipe management, lot traceability, and compliance with HACCP and FSMA regulations.

- 🔧 Discrete Manufacturing – Demands precision tracking of components, work-in-progress (WIP) monitoring, and seamless BOM (Bill of Materials) management.

How Industry Regulations Impact MES Selection

In regulated industries, an MES isn’t just a performance enhancer, it’s a compliance necessity. For example, in pharmaceuticals and food production, every production batch must have detailed electronic records for audits.

I’ve worked with companies that failed regulatory inspections because their MES lacked proper traceability. The result? Hefty fines, production shutdowns, and damage to brand reputation. If compliance is a major factor in your industry, make sure your MES is built to meet regulatory standards.

Scalability and Flexibility: Can Your MES Grow with Your Business?

I’ve seen manufacturers outgrow their MES within a few years, forcing them into costly system upgrades or even full replacements. A good MES should be scalable, meaning it can handle increasing production volumes, multiple plants, and new product lines without requiring a complete overhaul.

The Importance of a Future-Proof MES Solution

A future-proof MES should:

✅ Scale with production growth – Can it handle double or triple your current production volume?

✅ Support new technologies – Can it integrate with AI, IoT sensors, and machine learning in the future?

✅ Expand across multiple sites – If your company expands to new factories or global operations, can the MES manage it seamlessly?

I once worked with a company that implemented a low-cost, single-site MES, only to realize two years later that they needed multi-site production tracking. They had to switch to a completely different system, costing them millions in lost productivity and re-implementation fees.

Cloud-Based vs. On-Premise MES: Which One is Right for You?

I’ve worked with both cloud-based and on-premise MES solutions, and the best choice depends on your company’s needs:

☁️ Cloud-Based MES – Best for companies that:

- Need scalability and remote monitoring.

- Want to avoid high upfront IT costs.

- Have multiple factories that need centralized data access.

🏭 On-Premise MES – Preferred by companies that:

- Have strict security requirements (e.g., aerospace, defense).

- Require full control over data and system customization.

- Operate in locations with limited internet connectivity.

For most companies, cloud-based MES offers greater flexibility and scalability, especially with the rise of Industry 4.0 and remote factory management.

Integration with Existing Systems: Ensuring Seamless Data Flow

One of the biggest headaches I’ve seen in MES implementation is poor integration with existing systems. An MES should act as the central hub of production data, seamlessly connecting with:

- ERP (Enterprise Resource Planning) – Ensures production execution aligns with business goals.

- SCADA (Supervisory Control and Data Acquisition) – Collects real-time machine data for process control.

- IoT Sensors & Smart Machines – Enables predictive maintenance and automated workflows.

Avoiding Data Silos and Ensuring Smooth Interoperability

One company I worked with failed to integrate their MES with ERP, which resulted in misaligned production schedules and duplicate data entry. Operators had to manually input orders from ERP into MES, wasting hours of labor daily.

To prevent this, an MES should:

✔ Have API-based integration to connect with existing software.

✔ Enable real-time data sharing across platforms.

✔ Provide centralized dashboards that consolidate ERP, shop floor, and IoT data.

Without proper integration, MES can become just another isolated system, rather than the data-driven engine of a smart factory.

Real-Time Monitoring and Analytics: Unlocking

Modern MES solutions are no longer just data entry tools, real-time intelligence platforms. Real-time monitoring and AI analytics gauge competitive advantage.

An effective MES provides real-time dashboards

📊Track production performance in real time.

🚀 Identify bottlenecks before they cause delays.

📉 Monitor Key Performance Indicators (KPIs) like OEE (Overall Equipment Effectiveness).

I’ve personally seen companies boost their production efficiency by 20-30% simply breal-time MES dashboards to identify inefficiencies and optimize machine utilization.

How AI and Predictive Analytics Enhance MES Functionality

The most advanced MES solutions integrate AI-driven analytics, a

🔮 Predict machine failures before they happen

⚙️ Automatically adjust production schedules based on demand forecasts.

📈 Detect defects in real-time using AI-powered vision systems.

With AI-powered MES, companies can shift from reactive problem-solving to proactive optimization, saving money, improving quality, and increasing productivity.

From experience implementing MES across various industries, I can say this with confidence:

🔹 Choosing the right MES is one of the most critical technology investments a manufacturer can make.

🔹 A well-selected MES improves efficiency, reduces waste, and ensures long-term scalability.

🔹 Poorly chosen MES solutions create inefficiencies, integration challenges, and unnecessary costs.

MES Features You Should Look for: A Checklist for Manufacturers

Over the years, I’ve worked with numerous manufacturing companies implementing Manufacturing Execution Systems (MES), and one thing is clear: not all MES solutions are created equal. A well-implemented MES can streamline production, reduce waste, and boost efficiency, while a poorly chosen system can lead to frustration, inefficiencies, and costly delays.

To make sure your MES investment delivers maximum efficiency and ROI, I’ve put together a checklist of must-have MES functionalities that every manufacturer should look for.

Production Scheduling and Workflow Automation

One of the core functions of any MES is production scheduling and workflow automation. Without proper scheduling, even the most advanced factories struggle with bottlenecks, downtime, and inefficient resource allocation.

How MES Optimizes Manufacturing Processes

A good MES should act as the central hub that synchronizes machines, operators, and materials to ensure smooth production. It should allow manufacturers to:

✅ Automate scheduling based on real-time demand and machine availability.

✅ Dynamically adjust workflows in response to supply chain changes or equipment issues.

✅ Minimize human intervention in routine scheduling tasks, reducing manual errors.

I’ve seen manufacturers increase throughput by 20-30% simply by implementing MES-driven scheduling that automatically prioritizes jobs based on real-time production conditions.

Reducing Downtime and Maximizing Resource Utilization

Every manufacturer aims to reduce downtime, whether it’s due to machine maintenance, raw material shortages, or inefficient scheduling. A smart MES should provide:

⚡ Predictive maintenance alerts

Prevents unexpected breakdowns by scheduling repairs before failures occur.

Real-time workload balancing

Ensures machines and operators are fully utilized without overloading.

Automated rescheduling

Adapts to unexpected changes, such as material delays or urgent orders.

With the right MES, manufacturers spend less time firefighting and more time producing at peak efficiency.

Quality Management and Traceability: Ensuring Compliance and Product Integrity

In industries like pharmaceuticals, automotive, and food production, product quality and traceability are non-negotiable. A robust MES should serve as a digital quality control system, ensuring every product meets strict ISO, FDA, or GMP standards.

How MES Prevents Defects and Recalls

I’ve seen companies lose millions due to product recalls, many of which could have been prevented with a proper MES-driven quality control system. The right MES should:

- Monitor product quality in real time

Detecting deviations before defective products leave the production line.

- Capture and store inspection data

Providing a full audit trail for each batch or unit produced.

- Trigger automated alerts

Notifying operators and quality teams the moment a defect is detected.

By implementing MES with real-time defect detection, some manufacturers have reduced defect rates by up to 40%.

The Role of MES in Regulatory Compliance (ISO, FDA, GMP)

Regulated industries require strict compliance with global standards, and MES can be a powerful tool for documentation and audit preparation. A good MES should offer:

- Electronic Batch Records (EBR)

Essential for FDA compliance in pharmaceuticals.

- Lot and serial number traceability

Critical for GMP and ISO 9001 compliance.

🛠 Automated compliance reporting – Reducing manual paperwork for audits.

Having worked with highly regulated industries, I can say with certainty: a robust MES isn’t just a tool for efficiency, it’s an insurance policy against costly compliance failures.

Inventory and Materials Management: Enhancing Supply Chain Visibility

Raw material shortages and inventory mismanagement can grind production to a halt. An MES should enhance visibility across the supply chain, ensuring manufacturers always have the right materials at the right time.

Real-Time Tracking of Raw Materials and Finished Goods

The right MES should provide:

📦 Real-time material tracking – Ensuring accurate inventory levels at all times.

📍 Automated lot tracking – Preventing misplaced or expired raw materials.

🔄 Seamless integration with ERP systems – Aligning production schedules with inventory levels.

I’ve seen factories cut material waste by 25% simply by using MES-driven inventory tracking to prevent over-ordering and spoilage.

How MES Helps Reduce Waste and Improve Stock Accuracy

Manufacturers often struggle with material loss due to inefficient inventory control. An MES can help by:

✅ Automating raw material consumption tracking – Preventing excess usage.

✅ Optimizing reorder points – Ensuring stock never runs too low or too high.

✅ Reducing human errors in inventory management – Avoiding costly stock miscalculations.

For any manufacturer looking to improve supply chain efficiency, a real-time inventory tracking system in MES is a must.

Workforce and Operator Management: Boosting Human Efficiency

While automation is a key part of modern manufacturing, human workers still play a crucial role, and managing them efficiently can make a huge impact on productivity.

Skill-Based Task Assignments and Digital Work Instructions

A good MES should ensure that:

👷 Operators are assigned tasks based on skill level – Reducing errors and increasing efficiency.

📱 Work instructions are provided digitally

Eliminating paper-based SOPs.

📈 Training records and skill matrices are updated in real time

Ensuring only qualified personnel handle critical processes.

Tracking Operator Performance and Efficiency Metrics

MES should automate performance tracking, allowing managers to:

- ✔ Monitor real-time worker productivity.

- ✔ Identify inefficiencies in operator workflows.

- ✔ Provide data-driven feedback for continuous improvement.

Companies that leverage MES for workforce management often see higher worker engagement and lower turnover rates, because employees have clear visibility into their performance and training needs.

Customization and User-Friendliness: A System That Works for You

I’ve seen companies spend millions on MES solutions only to have operators refuse to use them because they were too complex. User adoption is just as important as system functionality.

How Configurable MES Interfaces Improve Adoption

Every manufacturer operates differently, which is why a rigid, one-size-fits-all MES often fails. A good MES should be configurable, allowing companies to:

✅ Customize dashboards for different roles (operators, managers, quality control).

✅ Modify workflows and reporting formats without requiring extensive coding.

✅ Adapt system settings to match unique production processes.

The Importance of Intuitive UX and Ease of Use

An MES should be designed for operators, not just IT teams. Key aspects of a user-friendly MES include:

🎨 Intuitive interface – Reducing training time for employees.

📊 Drag-and-drop workflow creationEnabling quick modifications.

🔔 Automated alerts and notifications – Keeping users informed without overwhelming them.

According to MES expert opinions, the most successful MES implementations are the ones that prioritize user-friendly design and configurability—because a system that’s hard to use is a system that won’t be used.

Conclusion

Choosing the right MES features can mean the difference between an optimized, highly efficient factory and a costly, frustrating implementation failure.

From production scheduling to quality control, inventory tracking, workforce management, and ease of use, a strong MES should align with business needs, industry standards, and long-term scalability.

The MES Implementation Process: A Roadmap to Success

Having been through multiple Manufacturing Execution System (MES) implementations, I can say one thing with confidence—a well-planned MES deployment can revolutionize a factory, but a poorly executed one can bring operations to a standstill.

MES is not just software; it’s an operational transformation that requires careful planning, cross-departmental collaboration, and ongoing optimization. I’ve seen companies rush into MES adoption without a clear strategy, leading to delays, wasted resources, and frustrated employees.

To avoid these pitfalls, manufacturers need to follow a structured roadmap for MES implementation. Here’s how to do it right.

Conducting a Needs Assessment: Understanding Your Business Requirements

Before even evaluating MES vendors, manufacturers must clearly define their goals and pain points. Skipping this step often results in choosing the wrong system, leading to misalignment with business needs.

How to Map Your Manufacturing Pain Points to MES Features

The first step is to identify your current inefficiencies. I always recommend asking these key questions:

- Where are the biggest inefficiencies in production? (e.g., frequent downtime, poor scheduling, high defect rates)

- What manual processes slow down operations? (e.g., paper-based tracking, manual data entry)

- What data insights do we lack? (e.g., real-time production monitoring, predictive analytics)

- Are we struggling with compliance? (e.g., missing audit trails, poor traceability)

Once these pain points are clear, manufacturers can map their needs to specific MES features. For example:

🚀 Production bottlenecks? → Look for real-time scheduling and workflow automation

📊 Lack of visibility? → Choose an MES with advanced dashboards and analytics

⚠ Regulatory compliance issues? → Prioritize traceability and audit features

Engaging Stakeholders for a Well-Rounded Selection Process

MES impacts multiple departments—not just IT or operations. I’ve seen implementations fail because key stakeholders weren’t involved in decision-making. To ensure success:

✅ Involve production managers – They know the day-to-day challenges on the shop floor.

✅ Engage IT teams – To ensure seamless integration with ERP and existing systems.

✅ Consult finance teams – To assess the ROI and long-term cost implications.

✅ Get operator feedback – Since they will be the ones using the system daily.

Without cross-functional collaboration, companies risk choosing an MES that looks good on paper but doesn’t solve real-world problems.

Planning for a Seamless MES Deployment

Once you’ve selected an MES, the next step is planning how to deploy it without disrupting production. This is where many companies get stuck—implementing too fast or too slow can both cause problems.

Phased vs. Full-Scale MES Implementation: Pros and Cons

There are two main approaches to MES deployment:

1️⃣ Phased Implementation – Rolling out MES in stages, starting with specific lines or plants.

2️⃣ Full-Scale Deployment – Implementing MES across all operations at once.

Phased Approach

✔ Lower risk – Allows for testing and adjustments before full rollout.

✔ Easier employee adoption – Training can be done in smaller batches.

✔ Less downtime – Since only parts of the factory are affected at a time.

❌ Slower full benefits – Takes longer to see company-wide ROI.

Full-Scale Deployment

✔ Immediate transformation – Fast-tracks efficiency and automation.

✔ Company-wide integration – Ensures all systems are connected from day one.

❌ Higher risk – If issues arise, they can impact the entire operation.

❌ More downtime – Requires intensive planning to avoid major disruptions.

According to expert opinions, most manufacturers benefit from a phased rollout, especially if they’re transitioning from a manual or legacy system.

Managing Downtime and Mitigating Risks During Transition

Downtime is one of the biggest fears during MES implementation. I always recommend these strategies to minimize production impact:

⚡ Schedule implementation during low-production periods – Avoid peak seasons to prevent revenue losses.

🛠 Run MES in parallel with existing systems – Until all critical functions are stable.

📋 Conduct pilot testing – Start with a small production area to identify issues before full deployment.

📢 Communicate with employees – Unexpected system changes can create frustration and resistance.

A well-planned deployment reduces risks and ensures that MES brings immediate value without disrupting operations.

Training and Change Management: Ensuring Employee Adoption

One of the most overlooked aspects of MES implementation is employee training and change management. The most advanced MES won’t deliver results if employees don’t know how to use it effectively.

How to Prepare Employees for the MES Shift

I’ve seen companies roll out MES with minimal training, assuming workers will “figure it out”—only to face frustration, workarounds, and resistance. To avoid this:

✅ Provide hands-on training – Classroom training is not enough; workers need real practice in the system.

✅ Create role-specific training programs – Operators, supervisors, and managers use MES differently.

✅ Offer digital work instructions and real-time guidance – Helps employees adjust faster.

Overcoming Resistance and Fostering a Digital Culture

Change is never easy, and MES adoption often meets resistance from employees who are used to old processes. The key to success? Transparency and involvement.

🔹 Explain the “why” – Show employees how MES will make their jobs easier, not harder.

🔹 Involve workers in the transition – Get operator feedback before deployment.

🔹 Appoint MES champions – Identify key users who can support and train others.

A well-managed change strategy ensures that MES isn’t just installed but fully embraced across the organization.

Measuring Success: Key Performance Indicators for MES

Once MES is up and running, how do you know if it’s delivering real value?

How to Track MES Effectiveness Through Data Analytics

A successful MES should improve key manufacturing KPIs, including:

📊 OEE (Overall Equipment Effectiveness) – Measures improvements in machine uptime and productivity.

⏳ Production Cycle Times – Faster production speeds indicate better workflow automation.

📉 Defect Rates – Lower defect counts mean quality control features are working.

📦 Inventory Accuracy – Reductions in stock discrepancies show better inventory tracking.

If these metrics don’t improve, it’s a sign that MES configuration or employee training may need adjustments.

Continuous Improvement Strategies Using MES Insights

The best MES systems don’t just track performance—they provide insights for continuous improvement. Manufacturers should:

✔ Use MES data for predictive maintenance – Preventing unplanned downtime.

✔ Optimize scheduling based on real-time demand – Reducing idle time and waste.

✔ Analyze operator efficiency – Identifying training needs and skill gaps.

Successful manufacturers don’t just implement MES and forget about it—they continuously refine and optimize workflows using MES insights.

Based on coaching experience, MES implementation is not just a technology project—it’s an operational transformation. Companies that follow a structured, well-planned deployment strategy see higher efficiency, better quality control, and significant cost savings.

🔹 Define clear business goals before selecting an MES.

🔹 Plan a deployment strategy that minimizes risk and downtime.

🔹 Invest in employee training and change management.

🔹 Continuously monitor KPIs to ensure long-term MES success.

With the right approach, MES can take manufacturing from reactive to proactive, manual to automated, and fragmented to seamlessly connected—unlocking the full potential of Industry 4.0.

The Future of MES: Trends and Innovations Shaping Next-Generation Systems

Having worked in the manufacturing technology space for years, I’ve seen Manufacturing Execution Systems (MES) evolve from basic production tracking tools into AI-driven, real-time decision-making platforms. The future of MES is no longer just about monitoring—it’s about predictive intelligence, automation, and seamless factory-wide connectivity.

With the rise of Industry 4.0, MES is undergoing a transformation driven by AI, cloud computing, IoT, and digital twin technology. Companies that embrace these innovations will gain a significant competitive edge, while those clinging to legacy systems risk falling behind.

Let’s take a deep dive into the biggest trends shaping the future of MES.

AI-Powered MES: Unlocking Predictive and Autonomous Manufacturing

The integration of artificial intelligence (AI) and machine learning (ML) into MES is revolutionizing how manufacturers predict failures, optimize production, and enhance quality control.

How Machine Learning is Transforming Production Efficiency

Traditional MES relied on historical data to analyze production trends. But AI-powered MES can:

✅ Analyze real-time production data to detect inefficiencies as they happen.

✅ Predict demand fluctuations and dynamically adjust production schedules.

✅ Optimize machine parameters in real time to minimize defects.

I’ve worked with manufacturers who have cut production cycle times by 15-20% by using AI-powered MES to automatically adjust workflows based on real-time data.

AI-Driven Defect Detection and Predictive Maintenance

One of the most exciting applications of AI in MES is automated defect detection. AI-powered vision systems can:

📸 Scan products in real time for defects, ensuring higher quality control.

🚨 Identify patterns that lead to defects and adjust production before issues arise.

⚙ Reduce human inspection errors and speed up quality assurance processes.

Similarly, AI-driven predictive maintenance is saving companies millions by:

🛠 Predicting machine failures before they happen, preventing unexpected downtime.

📊 Analyzing sensor data to schedule maintenance only when needed, extending machine life.

🔧 Reducing repair costs by preventing catastrophic equipment failures.

With AI-powered MES, manufacturers can move from reactive problem-solving to proactive and even autonomous manufacturing operations.

The Rise of Cloud-Based MES: Benefits and Challenges

The shift from on-premise MES to cloud-based solutions is one of the biggest transformations happening in the industry. As manufacturers expand globally and adopt remote operations, cloud MES solutions are becoming the new standard.

How SaaS MES Solutions Enhance Scalability and Accessibility

Traditionally, MES systems required heavy on-premise infrastructure, making them costly and difficult to scale. Cloud-based MES, often delivered as Software-as-a-Service (SaaS), solves these problems by offering:

☁️ Global accessibility – Teams can monitor and control production from anywhere.

📈 Easy scalability – Adding new production lines or factories is faster and more cost-effective.

💸 Lower upfront costs – No need for expensive on-premise servers and IT maintenance.

One manufacturer I worked with expanded from a single factory to five locations worldwide without major IT headaches, thanks to a cloud MES that scaled seamlessly.

Addressing Security and Data Privacy Concerns in Cloud MES

While cloud MES offers numerous advantages, some companies hesitate due to security and compliance concerns. Key challenges include:

🔐 Data security risks – Sensitive manufacturing data is stored off-site, requiring strong encryption and access controls.

⚖️ Regulatory compliance – Industries like pharmaceuticals and aerospace have strict data privacy laws that cloud providers must comply with.

🌐 Internet reliability – Cloud MES relies on stable connectivity, which may be a concern in remote facilities.

Leading MES providers are addressing these concerns by offering:

✔ End-to-end encryption and multi-factor authentication.

✔ Compliance certifications (ISO 27001, GDPR, NIST).

✔ Hybrid solutions that combine cloud flexibility with on-premise security.

For most manufacturers, the benefits of cloud MES far outweigh the risks, especially with modern cybersecurity advancements.

MES and IoT: The Smart Factory Connection

The Internet of Things (IoT) is playing a massive role in shaping the next generation of MES. By integrating real-time sensor data, MES can provide unprecedented visibility and automation in manufacturing operations.

How Real-Time IoT Sensor Data Enhances MES Functionality

IoT-enabled MES connects to smart sensors and machines, allowing manufacturers to:

📡 Collect real-time data on machine performance, temperature, pressure, and vibration.

⚙ Automatically adjust production settings based on live sensor readings.

🚀 Optimize energy consumption by dynamically controlling power usage.

One factory I worked with integrated IoT-driven MES and saw a 30% improvement in energy efficiency by automatically adjusting machine speeds based on workload.

Improving Predictive Maintenance with IoT-Enabled MES

IoT sensors allow MES to predict equipment failures before they happen by:

🔍 Detecting subtle changes in vibration, temperature, or performance.

📊 Analyzing sensor trends to determine when a machine needs maintenance.

🔄 Triggering automated service requests before failures occur.

This shift to IoT-powered predictive maintenance is drastically reducing downtime and repair costs across industries.

The Role of Digital Twins in MES: Simulating and Optimizing Production

One of the most exciting innovations in MES is the use of digital twins—virtual models that provide a real-time mirror of physical factory operations.

How Digital Twins Provide a Real-Time Mirror of Factory Operations

A digital twin is a virtual replica of a production line, machine, or entire factory, allowing manufacturers to:

🖥 Simulate production scenarios before making real-world changes.

📊 Analyze how different variables affect efficiency.

🔄 Test new workflows and machine configurations without disrupting actual production.

I’ve seen manufacturers use digital twins to test process improvements in a virtual environment, leading to optimized efficiency without any risk.

Reducing Waste and Improving Accuracy with Virtual Testing

Digital twins help manufacturers:

✅ Identify inefficiencies before implementing changes.

✅ Optimize supply chain logistics by simulating inventory fluctuations.

✅ Improve production accuracy by predicting how raw materials behave in different conditions.

For high-precision industries like aerospace, semiconductors, and pharmaceuticals, digital twins are becoming an essential tool for risk-free process optimization.

The future of MES is no longer just about tracking production—it’s about intelligence, automation, and seamless connectivity. With advancements in AI, cloud computing, IoT, and digital twins, MES is evolving into a predictive, self-optimizing system that drives next-level efficiency and quality.

Manufacturing Execution System (MES) FAQ:Everything You Need to Know

(Comprehensive Answers to Common Questions About MES, Covering Practical and Technical Aspects)

1. What is a Manufacturing Execution System (MES)?

A Manufacturing Execution System (MES) is a software solution that monitors, tracks, and controls manufacturing operations in real-time. It acts as a bridge between Enterprise Resource Planning (ERP) systems and shop-floor equipment, ensuring efficient production, quality control, and data-driven decision-making.

2. Why is MES Important for Modern Manufacturing?

MES is crucial because it:

- Optimizes production efficiency by reducing downtime and waste

- Improves product quality with real-time defect tracking

- Enhances traceability for regulatory compliance (e.g., FDA, ISO, GMP)

- Provides real-time data analytics to improve decision-making

- Seamlessly integrates with ERP, SCADA, and IoT systems

Without MES, manufacturers struggle with data silos, inefficiencies, and inconsistent quality.

3. What Are the Core Functions of an MES?

A robust MES typically includes:

- Production Scheduling & Workflow Automation – Streamlining manufacturing processes

- Quality Management & Traceability – Ensuring defect-free production

- Inventory & Material Management – Optimizing raw materials and finished goods

- Performance Monitoring & KPI Tracking – Providing real-time dashboards

- Workforce & Operator Management – Assigning tasks based on skill level

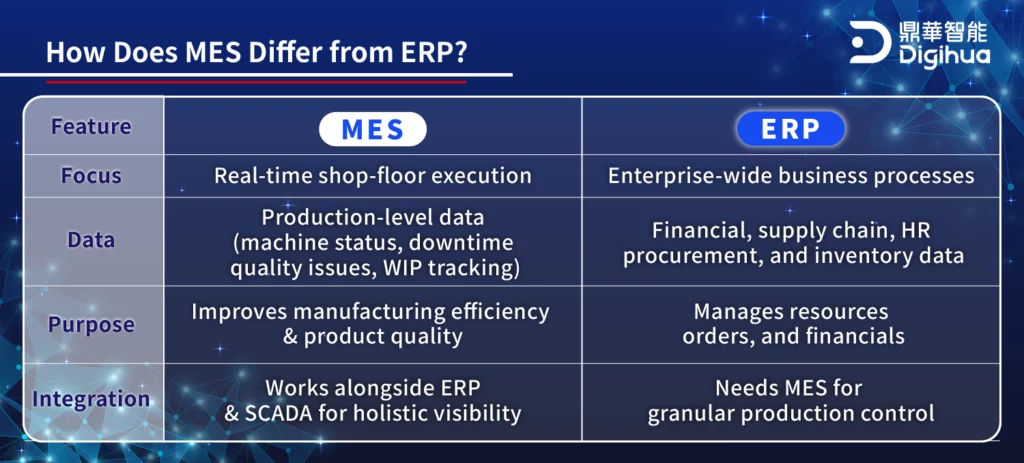

4. How Does MES Differ from ERP?

| Feature | MES | ERP |

| Focus | Real-time shop-floor execution | Enterprise-wide business processes |

| Data | Production-level data (machine status, downtime, quality issues, WIP tracking) | Financial, supply chain, HR, procurement, and inventory data |

| Purpose | Improves manufacturing efficiency & product quality | Manages resources, orders, and financials |

| Integration | Works alongside ERP & SCADA for holistic visibility | Needs MES for granular production control |

While ERP focuses on business processes and financials, MES optimizes shop-floor execution and real-time production control.

5. What Industries Benefit Most from MES?

MES is widely used in:

- Automotive – Optimizing assembly lines and quality checks

- Pharmaceuticals & Biotech – Ensuring FDA/GMP compliance and batch tracking

- Food & Beverage – Improving traceability and safety compliance

- Electronics & Semiconductor – Enhancing precision in high-tech manufacturing

- Aerospace & Defense – Managing complex production workflows and quality

6. What is the Difference Between Cloud-Based and On-Premise MES?

| Feature | Cloud-Based MES | On-Premise MES |

| Deployment | Hosted on a cloud provider’s server | Installed on local company servers |

| Cost | Lower upfront cost, subscription-based | Higher upfront cost, but no recurring fees |

| Scalability | Highly scalable and flexible | Limited by infrastructure |

| Security | Provider-managed security | Full in-house control over security |

| Maintenance | Vendor handles updates & patches | IT team responsible for updates |

Cloud MES is ideal for scalability and cost efficiency, while on-premise MES offers better security and control.

7. How Long Does It Take to Implement an MES?

The implementation timeline depends on:

- Business size & complexity – Larger factories need longer rollouts

- Integration requirements – MES-ERP and MES-IoT integration takes time

- Training & adoption – Employee readiness affects deployment speed

On average, MES implementation takes 3 to 12 months, but phased rollouts help minimize disruptions.

8. What Are the Common Challenges of MES Implementation?

- Resistance to Change – Employees may resist new systems

- Integration Issues – Ensuring seamless ERP, IoT, and SCADA connections

- Customization Complexity – Aligning MES features with company needs

- High Initial Costs – Significant upfront investment for hardware/software

Proper training, stakeholder engagement, and phased deployment can help overcome these challenges.

9. How Much Does an MES Cost?

MES costs vary based on:

💰 Vendor & Licensing Model – SaaS (subscription) vs. Perpetual License

💰 Deployment Type – Cloud-based is more affordable than on-premise

💰 Customization Needs – Highly tailored MES solutions are more expensive

💰 Integration Complexity – Connecting MES to ERP, IoT, and legacy systems adds costs

Cost Range:

- Small manufacturers: $50,000 – $250,000

- Mid-sized enterprises: $250,000 – $1M

- Large corporations: $1M+

The ROI is typically achieved within 1-3 years due to increased efficiency and reduced waste.

10. How to Choose the Best MES for Your Business?

When selecting an MES, consider:

- Industry-Specific Features – Ensure compatibility with your manufacturing type

- Scalability & Flexibility – Can it grow with your business?

- User-Friendliness – How easy is it for operators to adopt?

- Integration Capabilities – Does it work with your ERP, IoT, and automation systems?

- Vendor Support & Reliability – Strong customer service and regular updates

Requesting demos and pilot testing before full deployment is highly recommended.

11. What Are the Future Trends in MES?

- AI & Machine Learning Integration – Predictive analytics for process optimization

- IoT-Connected Smart Factories – Real-time sensor data improving automation

- Cloud & Edge Computing – Faster, scalable, and more flexible deployments

- Digital Twins & Simulation – Virtual modeling of production processes

- Sustainability & Green Manufacturing – Reducing energy consumption and waste

The next-gen MES will focus on intelligent, autonomous manufacturing driven by AI and IoT.

12. Can a Small or Mid-Sized Manufacturer Benefit from MES?

💡 Yes! MES is not just for large enterprises. Small and mid-sized manufacturers can benefit from:

✔ Cloud-based MES – Lower costs, faster implementation

✔ Modular MES Solutions – Start with essential features, scale up as needed

✔ Improved Efficiency & Quality – Reduced rework, better production planning

Many vendors offer affordable, industry-specific MES tailored for SMEs.

Final Thoughts: Is MES Worth the Investment?

✅ If you need real-time production visibility, improved efficiency, and better quality control, MES is a must-have.

✅ Choosing the right MES vendor and proper implementation strategy ensures maximum ROI.

✅ As manufacturing moves towards smart factories, MES will become essential for staying competitive.

Start by evaluating your business needs and engaging with MES providers for demos and consultations!🚀

Conclusion: Choosing the Best MES is the Key to Future-Proofing Your Manufacturing

After working with various manufacturers implementing Manufacturing Execution Systems (MES), I’ve seen firsthand how the right MES can transform operations—and how the wrong one can become a costly mistake.

Many companies treat MES selection as just another IT project, but the reality is that it’s a strategic decision that impacts production efficiency, quality control, and long-term scalability. Choosing the best MES isn’t just about what works today, but about ensuring that your manufacturing operations remain competitive for years to come.

Before making a final decision, let’s summarize the key takeaways and next steps to help you navigate the MES selection process.

Key Takeaways: The Essentials of Selecting the Right MES

Why MES Selection Should Be a Strategic Decision, Not Just a Tech Upgrade

Too often, companies rush into MES adoption without fully understanding their business needs. But an MES is not just software—it’s a core component of smart manufacturing that will directly impact production efficiency, cost savings, and scalability.

According to MES expert opinions, the companies that succeed with MES follow these strategic principles:

✅ Align MES with long-term business goals – Consider scalability, industry regulations, and future expansion.

✅ Choose an MES that integrates seamlessly – It must connect with ERP, SCADA, IoT devices, and cloud platforms.

✅ Prioritize usability and workforce adoption – Even the best MES is useless if employees struggle to use it effectively.

✅ Invest in training and change management – Successful MES implementation depends as much on people as on technology.

Avoiding Common Mistakes and Ensuring Long-Term MES Success

Through trial and error, I’ve seen some major MES mistakes that manufacturers should avoid:

❌ Focusing only on cost – A cheaper MES may lack key features, leading to higher long-term costs.

❌ Choosing a one-size-fits-all solution – Industry-specific MES yields better performance and compliance.

❌ Skipping stakeholder involvement – Ensure operations, IT, finance, and quality control teams have input.

❌ Underestimating integration challenges – If MES doesn’t sync seamlessly with ERP and shop floor systems, data silos will emerge.

A carefully chosen and well-implemented MES doesn’t just track production—it optimizes workflows, reduces waste, and future-proofs operations.

Next Steps: How to Start Your MES Selection Journey Today

Now that we’ve covered why MES is critical, here’s how to get started on selecting and implementing the right system for your manufacturing needs.

Conducting an Internal MES Readiness Assessment

Before reaching out to vendors, manufacturers should assess their internal needs and constraints. I always recommend companies ask:

📊 What are our biggest production challenges? (e.g., downtime, inefficiency, lack of visibility)

🔄 What manual processes do we need to automate? (e.g., paper-based tracking, manual data entry)

🔗 What systems do we need MES to integrate with? (ERP, IoT, SCADA, inventory management)

📈 What KPIs will determine MES success? (OEE, cycle times, defect rates, labor efficiency)

💰 What is our budget and expected ROI? (Short-term vs. long-term benefits)

This assessment will help narrow down MES options and prevent wasting time on unsuitable solutions.

Engaging with MES Vendors and Requesting Demos for Evaluation

Once you have a clear understanding of your needs, the next step is to engage with MES vendors. Here’s how to do it effectively:

✅ Create a vendor shortlist – Based on industry fit, integration capability, and scalability.

✅ Request live demos – See how the system works in a real-world manufacturing scenario.

✅ Ask for customer references – Speak to other manufacturers who have implemented the MES.

✅ Run a pilot program – Test the MES on a small scale before full implementation.

✅ Negotiate customization options – Ensure MES can adapt to unique workflows and compliance needs.

From experience, the best MES vendors don’t just sell software—they act as long-term partners, helping companies optimize their implementation and continuously improve efficiency.

Final Thoughts

Selecting the right MES is one of the most important investments a manufacturer can make. When done right, it improves productivity, enhances quality control, optimizes resources, and lays the foundation for future growth.

To ensure success:

🔹 Assess your current pain points and define clear MES goals.

🔹 Choose an MES that integrates seamlessly with existing systems.

🔹 Prioritize usability and training for long-term workforce adoption.

🔹 Engage with reputable vendors and test solutions before committing.

With the right strategy, MES isn’t just a tool—it’s a transformational asset that drives long-term success in Industry 4.0 and beyond.

Manufacturing Execution System (MES) Provider「DigiHua」

DigiHua is a leading smart manufacturing solutions provider, offering advanced software and services tailored for the semiconductor, electronic assembly, and discrete manufacturing industries. With over 27 years of experience, DigiHua specializes in intelligent manufacturing and industrial Internet of Things (IIoT) applications, serving clients across Taiwan, Mainland China, and the Asia-Pacific region.

Their comprehensive product suite includes:en.digihua.com

- sMES (Smart Manufacturing Execution System): Enhances real-time production management by integrating personnel, equipment, materials, methods, and measurements, leading to improved efficiency and quality control.

- sAPS (Smart Advanced Planning and Scheduling): Provides intelligent scheduling solutions that address challenges like fluctuating order volumes and resource allocation, ensuring timely deliveries and optimized production plans.

- sQMS (Smart Quality Management System): Offers dynamic quality management tools, including real-time inspection, statistical process control, and failure mode analysis, to achieve zero-defect manufacturing goals.

DigiHua’s solutions have been successfully implemented in over 1,800 manufacturing enterprises, including more than 180 semiconductor clients, establishing over 36 intelligent demonstration bases across the Asia-Pacific.

For more information on how DigiHua can support your smart manufacturing transformation, visit their official website: https://en.digihua.com/.