Explore how to choose the best Advanced Planning and Scheduling (APS) software system solution for your business. Learn key features, benefits, and selection tips.

What Is Advanced Planning and Scheduling(APS)?

Definition and Core Objectives of APS

Advanced Planning and Scheduling (APS) is an intelligent production scheduling system that analyzes real-time constraints such as capacity, materials, and manpower to generate the most efficient manufacturing plan and schedule.

APS is not just an upgrade to traditional planning, it’s a paradigm shift. It is a system that leverages real-time data, constraint-based algorithms, and multi-layered synchronization across departments to generate optimized production schedules. Unlike legacy systems, APS dynamically adjusts to variables like machine capacity, labor availability, order priority, and supply chain fluctuations.

As a Senior Smart Manufacturing Consultant, I’ve worked with countless manufacturing firms navigating the complexities of modern production environments. One of the most transformative tools I recommend and implement across industries is Advanced Planning and Scheduling (APS).

From my consulting experience, the core objectives of APS are:

-

- Optimizing resource allocation to reduce waste and improve throughput.

-

- Aligning production plans with actual capacity, ensuring realistic and executable schedules.

-

- Enhancing responsiveness to demand changes and disruptions through real-time re-planning.

-

- Supporting strategic planning via simulation tools, helping decision-makers evaluate multiple scenarios before execution.

Limitations of Traditional Scheduling Methods

Before companies adopt APS, many of them struggle with outdated scheduling methods, something I encounter regularly during digital maturity assessments. These methods often rely on Excel sheets, disconnected modules in ERP systems, or even manual whiteboard planning. In today’s complex manufacturing world, such approaches are no longer sufficient.

Here are the most common limitations I’ve observed:

-

- Rigid structures that don’t accommodate last-minute order changes or machine downtimes.

-

- Fragmented data that leads to misalignment between procurement, production, and sales.

-

- Reactive rather than proactive decision-making, which results in missed deadlines and rising costs.

-

- Inability to optimize across constraints, causing bottlenecks and underutilization of key resources.

In many cases, planners are left juggling priorities without clear visibility, which inevitably affects efficiency and customer satisfaction.

The Role and Importance of APS in Modern Manufacturing

The modern manufacturing landscape, characterized by volatility, customization, and sustainability requirements, demands more than traditional MRP or scheduling tools. This is where APS becomes indispensable.

In my role as a consultant, I’ve seen firsthand how implementing APS can completely transform an organization’s operations. It plays a crucial role in:

-

- Synchronizing supply chain and shop floor operations, ensuring end-to-end visibility and agility.

-

- Reducing lead times, improving on-time delivery, and significantly lowering operational costs.

-

- Increasing resilience by enabling dynamic reallocation of resources in response to disruptions.

-

- Providing strategic foresight, allowing executives to make informed, data-driven decisions supported by predictive analytics.

What truly sets APS apart is its ability to bridge the gap between long-term strategic planning and short-term operational execution. It empowers manufacturers to move beyond firefighting and embrace continuous improvement, which aligns perfectly with the principles of Industry 4.0 and smart factory initiatives.

From my consulting perspective, APS is not just a system, it’s a foundational component for any enterprise serious about achieving manufacturing excellence in today’s competitive and digitally driven world.

Core Features and Key Problems Solved by APS

After years of guiding manufacturing companies through digital transformation, I can confidently say that Advanced Planning and Scheduling (APS) is one of the most powerful solutions available for tackling the real, everyday challenges on the shop floor. Below, I’ll walk you through the core features that make APS indispensable, and the persistent problems it solves that traditional methods simply can’t address.

Automated and Optimized Scheduling: Reducing Human Errors

In my consulting work, I often see production teams relying heavily on manual scheduling, which not only consumes time but is also prone to human error. APS eliminates this by automating the scheduling process with advanced algorithms that consider all variables, shift calendars, setup times, changeovers, machine availability, and more.

This level of automation has dramatically reduced planning mistakes for my clients. The result? Fewer delays, more accurate delivery timelines, and a noticeable boost in planner confidence.

Capacity-Constrained Planning: Avoiding Overload and Bottlenecks

One of the most common issues I encounter in factories is overloading certain resources while underutilizing others. APS addresses this by applying capacity-constrained planning, which means every job is scheduled only when the required machines, labor, and tools are available, without exceeding their limits.

This capability has been a game changer. By visualizing load balancing and predicting bottlenecks before they happen, manufacturers can proactively adjust plans, redistribute workloads, and ensure smooth, uninterrupted operations.

Synchronizing Material Requirements: Preventing Shortages and Overstocking

Many manufacturers struggle with raw material issues, either running short during critical production runs or stockpiling excess inventory that ties up capital. APS tackles this by tightly integrating with Material Requirements Planning (MRP) and synchronizing production schedules with procurement and inventory systems.

For clients I’ve worked with, this integration has drastically improved material flow accuracy. It helps avoid costly line stoppages due to missing components and eliminates unnecessary inventory holding costs, which is a win-win across both operations and finance.

Real-Time Simulation and Dynamic Adjustment

In fast-paced manufacturing, static schedules are obsolete the moment something changes. APS empowers teams with real-time simulation and dynamic re-scheduling capabilities. Whenever there’s a disruption, such as a rush order, equipment breakdown, or late supplier delivery, APS can simulate multiple what-if scenarios and instantly recommend the best course of action.

This flexibility is invaluable. I’ve seen clients reduce production delays by over 30% simply by adopting this feature, allowing them to remain agile even in unpredictable environments.

Visualized Data and Decision Support for Operations

Finally, APS is not just about automation, it’s also about insightful decision-making. The systems I implement often include visual dashboards and KPI tracking that present planners and managers with an up-to-date overview of production status, resource utilization, order progress, and more.

By turning raw data into actionable insights, APS gives decision-makers the clarity they need to align day-to-day operations with strategic goals. Whether it’s deciding on overtime, outsourcing, or shifting delivery dates, the visualized data enables fast and confident decision-making.

Key Factors to Consider Before Choosing APS Software

Selecting the right Advanced Planning and Scheduling (APS) solution isn’t simply a matter of comparing product brochures. Over the years, I’ve helped many manufacturers make this critical decision, and I’ve learned that a successful APS implementation depends on a careful evaluation of several interconnected factors. Here’s what I always advise clients to consider before making their investment.

Assessing Company Scale and Industry Needs

Every company has a unique operational rhythm, and APS is never a one-size-fits-all solution. One of the first things I do with clients is evaluate their organizational scale and industry-specific requirements. For instance, a high-mix, low-volume job shop will have vastly different scheduling needs compared to a continuous process manufacturer in chemicals or food production.

If you’re a growing SME, you might not need the full suite of features a large enterprise requires, but you’ll want room to scale. Start by clearly defining your production model, pain points, and future goals. Only then can you identify which APS systems are truly built for your needs.

Matching Core Modules and Functional Fit

In my experience, too many companies fall into the trap of buying the most feature-rich software, only to find themselves overwhelmed or unable to utilize half the tools. That’s why functional fit is crucial.

I encourage clients to prioritize core modules like finite capacity scheduling, constraint management, material synchronization, and order prioritization. Don’t be swayed by shiny extras unless they directly solve a known problem. Ensure the solution supports your specific workflows and decision logic, rather than forcing your team to adapt to a rigid software structure.

Integration and Compatibility with Existing Systems

APS doesn’t operate in isolation, it has to communicate smoothly with your ERP, MES, WMS, and even SCADA systems. One of the biggest failure points I’ve seen in past projects is underestimating the complexity of system integration.

Before making a decision, I always assess how well a potential APS system integrates with the client’s existing tech stack. Look for systems with open APIs, proven ERP connectors, and a flexible architecture. If your current systems can’t exchange data seamlessly with the APS, the benefits will be limited, and frustration will be high.

Budget Planning and Total Cost of Ownership (TCO)

Price tags can be misleading. A lower upfront cost may look appealing, but it’s the Total Cost of Ownership (TCO) that reveals the true picture. In my role, I help clients assess both initial licensing fees and long-term costs, including customization, integration, training, maintenance, and upgrade fees.

Consider not only your budget today but your financial roadmap over the next 3 to 5 years. Also, calculate potential ROI in terms of labor savings, inventory reduction, improved on-time delivery, and other measurable benefits.

Vendor Reputation and Local Support Availability

One lesson I’ve learned the hard way is that vendor reliability matters just as much as product quality. No matter how promising a solution looks, its success hinges on the people behind it. I always encourage clients to look into a vendor’s track record, case studies, customer testimonials, and longevity in the market.

Even more importantly, ask: Do they have support staff in your region or time zone? When something breaks, you want quick help from someone who understands your industry and speaks your language, not a ticketing system lost in a different continent.

User Interface Friendliness and Training Requirements

I’ve seen brilliant software fail simply because it was too complex for end users. An intuitive, user-friendly interface can make all the difference in adoption rates. If planners, schedulers, and operations teams can’t navigate the system with ease, they’ll revert to their old ways, and your investment will stagnate.

Training is another key factor. Make sure the vendor offers robust onboarding, hands-on sessions, and ongoing education. Ideally, the system should also support role-based dashboards and workflows tailored to planners, operators, and executives.

Common Challenges and Success Factors in APS Implementation

From my years of guiding manufacturers through digital transformation, I’ve learned that implementing an Advanced Planning and Scheduling (APS) system is never just about installing software, it’s about reshaping how a business plans, decides, and responds. While the benefits of APS are significant, the journey to get there is rarely smooth. Here are the most common challenges I’ve helped clients navigate, and the success factors that separate failed projects from thriving ones.

Data Collection and Accuracy Issues

One of the first stumbling blocks I often see is poor data quality. APS systems rely on accurate, real-time data to function correctly, garbage in, garbage out. Unfortunately, many companies discover too late that their master data is incomplete, inconsistent, or outdated.

In my initial assessments, I typically find mismatches in BOMs, incorrect cycle times, or missing routing data. To address this, I always stress the importance of data cleaning and validation as a pre-project milestone. Without reliable data, even the most advanced APS engine will produce flawed schedules that no planner can trust.

Internal Process Reengineering and Employee Resistance

APS implementation often requires a rethinking of how production planning and execution are done. But change, especially in manufacturing, is rarely embraced with open arms. I’ve seen talented planners resist new systems simply because they feel their expertise is being replaced, or because the new workflow challenges years of muscle memory.

This is why I emphasize that APS adoption isn’t just about technology, it’s about internal process reengineering. You’ll need to revisit old workflows, eliminate manual overrides, and build standard operating procedures around the new tool. The key is to involve employees early, value their input, and show how APS will enhance rather than replace their role.

Cross-Department Communication and Change Management

APS affects far more than just the production department. Procurement, inventory, logistics, sales, all must align with the new planning model. But if departments remain in their silos, APS becomes a source of friction instead of integration.

I always recommend establishing a cross-functional project team to ensure alignment. This team serves as the communication bridge, helping translate system changes into department-specific terms. I also encourage companies to implement structured change management programs, including communication plans, milestone celebrations, and visible executive support to keep morale and momentum high.

Budget Control and Project Timeline Risks

Like any major enterprise system, APS implementation is susceptible to scope creep, unforeseen costs, and delays. I’ve seen projects stall due to underestimated integration complexity or lack of internal resources.

To mitigate this, I advise clients to create a phased implementation roadmap with clear deliverables, budget buffers, and risk contingency plans. Don’t try to roll out everything at once, start with a pilot area, learn from it, and expand in controlled stages. Having a dedicated project manager, whether internal or external, is also crucial for keeping the timeline and resources in check.

Critical Success Factors for a Smooth APS Rollout

Based on my hands-on experience across different industries, here are the five critical success factors I always highlight to clients for a successful APS rollout:

-

- Top-down executive support: Leadership must not only approve the project but actively champion it.

-

- Reliable and cleaned master data: The foundation for accurate planning must be laid well before go-live.

-

- Cross-functional collaboration: Success comes when departments work together toward shared KPIs.

-

- User training and change readiness: People make systems work, continuous training is non-negotiable.

-

- A realistic and phased implementation plan: Prioritize quick wins that demonstrate value early.

APS can transform operations, but only if the human, technical, and procedural components are aligned. When companies get this right, the return on investment isn’t just financial, it’s strategic, cultural, and operational.

Integration of APS with ERP/MES Systems

As a Senior Smart Manufacturing Consultant, I often get asked whether APS replaces ERP or MES, and my answer is always the same: APS doesn’t replace; it enhances. Its value is fully realized only when it is tightly integrated into the broader IT landscape. Let me walk you through what I’ve seen in real-world deployments and how successful companies connect these systems for maximum value.

Differences and Complementary Roles: APS vs ERP

In many client projects, I start by clarifying a critical distinction: ERP is transactional; APS is analytical.

ERP systems are designed to record and manage enterprise transactions, sales orders, inventory movements, invoices, and so on. They excel at “what happened” and “what is”, but they’re not built to optimize future scenarios or handle complex constraints across the production floor.

That’s where APS steps in. APS focuses on “what should happen, when, and with what resources”. It runs sophisticated algorithms to generate optimized production schedules, considering constraints that ERP typically ignores, like machine availability, setup times, labor capacity, and material readiness.

In short, ERP tells you what’s available, while APS tells you how to best use it. When combined, they become a powerful engine for responsive, data-driven manufacturing.

Key Synergy Points Between APS and MES

If ERP and APS form the planning brain, MES (Manufacturing Execution System) is the operational nervous system, capturing events and statuses from the shop floor in real time. I always emphasize this triangle of synergy: ERP + APS + MES = Real-Time Optimization.

In practical terms:

-

- APS pulls actual production status updates from MES to adjust plans in real time.

-

- MES executes the APS-generated schedule, dispatching work orders and collecting feedback.

-

- ERP handles order transactions and records the financial/business side of operations.

I’ve seen this synergy reduce downtime, improve schedule adherence, and give planners the agility to respond to changes within minutes rather than days.

Interface Development and Data Synchronization Considerations

Now, let’s talk integration, where many projects stumble if not planned well. The success of APS depends heavily on how well it communicates with ERP and MES. This requires robust interface development, which involves defining:

-

- What data flows in and out (orders, inventory, capacity, status updates)

-

- How often it syncs (real-time, batch, or hybrid)

-

- How errors and conflicts are handled

- How errors and conflicts are handled

From experience, I always recommend bi-directional interfaces with clear data ownership rules. For example, ERP owns master data, APS owns the schedule, and MES owns real-time execution data. Having an interoperability framework or middleware layer can greatly reduce the complexity and speed up deployment.

Also, don’t underestimate the need for clean and structured data. Even the best interface can’t overcome chaotic BOMs, inconsistent routings, or manual data entry errors.

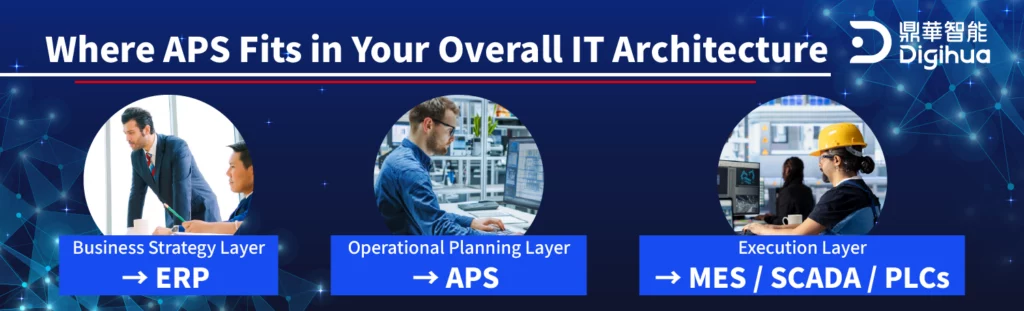

Where APS Fits in Your Overall IT Architecture

In modern smart factories, APS occupies a very strategic position, right between planning and execution layers. Here’s how I typically map it for clients:

-

- Business Strategy Layer → ERP (Enterprise Resource Planning)

-

- Operational Planning Layer → APS (Advanced Planning & Scheduling)

-

- Execution Layer → MES / SCADA / PLCs (Shop Floor Control)

By sitting in the middle, APS acts as a bridge:

-

- Upward to ERP, it aligns production planning with business priorities.

-

- Downward to MES, it ensures execution aligns with optimal resource utilization.

When designed properly, APS becomes the dynamic link that synchronizes long-term goals with real-time shop floor conditions. It transforms your IT architecture from a static hierarchy into a feedback-driven, adaptive system, a key milestone in any Industry 4.0 roadmap.

Case Study: APS in Semiconductor Substrate Manufacturing

One of the most dynamic APS implementations I led was for a leading manufacturer of advanced semiconductor substrates. Their products are used in high-performance computing, 5G, AI, IoT, and automotive electronics—an industry defined by tight delivery windows, complex product mix, and constantly shifting customer demands.

The client faced several pressing challenges: production lines were distributed across multiple zones with limited visibility into real-time loading; equipment groups operated in silos; and frequent priority changes from key accounts often led to line imbalances and missed shipment deadlines. Traditional systems couldn’t handle the level of coordination required.

To solve this, we deployed an APS solution integrated with their MES to enable synchronized scheduling and dispatching across zones. Key capabilities included:

-

- Dynamic and static load balancing to proactively adjust production loads across equipment clusters.

-

- Visualized dashboards for real-time transparency between order intake and shop floor capacity.

-

- Scenario simulation and fine-grained dispatching that allowed planners to respond immediately to changes in order mix or supply delays.

-

- A three-tier management model focused on visibility, coordination, and precision: see far, see across, and see deep.

The impact was transformative:

-

- Scheduling efficiency improved 8x compared to their previous approach.

-

- All dispatched plans became 100% executable, thanks to real-time validation against machine status and resource readiness.

-

- The organization gained the agility to fulfill urgent customer requests without sacrificing existing commitments.

This case highlighted how APS, when combined with MES and a strategic planning mindset, can turn a fragmented production environment into a synchronized, high-speed operation ready for the demands of modern semiconductor manufacturing.

How to Evaluate APS ROI (Return on Investment)

One of the most common questions I get from decision-makers, whether they’re COOs, plant managers, or CFOs, is: “How do we measure whether APS is really worth it?” And to be honest, that’s the right question to ask. APS is a strategic investment, and understanding its return involves both tangible and intangible factors. In this section, I’ll break down how I help clients assess the real ROI of implementing Advanced Planning and Scheduling systems.

Measuring Productivity Gains and Capacity Utilization

The first place I look when evaluating APS ROI is productivity and machine utilization. Before implementation, most companies I work with experience idle time, unbalanced workloads, and firefighting due to scheduling chaos.

With APS, we often see:

-

- Increased throughput per hour due to better job sequencing.

-

- Fewer changeovers and less downtime as the system clusters similar jobs.

-

- More effective labor deployment, reducing unnecessary overtime.

I recommend tracking OEE (Overall Equipment Effectiveness) and comparing before-and-after metrics. In many cases, I’ve seen clients unlock an additional 10–20% of hidden capacity, without adding any new machines or people.

Inventory Cost Reduction and Operational Efficiency

APS also contributes significantly to inventory cost savings. Many manufacturers run high stock levels “just in case,” due to lack of planning confidence. Once APS brings clarity and synchronization across procurement and production, inventory strategies shift from reactive to proactive.

Here’s what I typically help clients measure:

-

- Reduction in raw material buffer stocks.

-

- Less WIP (Work in Progress), thanks to better job timing.

-

- Lower finished goods inventory, due to tighter make-to-order alignment.

Beyond the numbers, this frees up warehouse space, improves cash flow, and reduces obsolescence, especially critical for sectors like electronics or food.

On-Time Delivery Rate Improvement and Customer Satisfaction

For most clients I work with, on-time delivery (OTD) is the single most important KPI, and often the most visible to customers. APS enhances OTD by offering planners real-time visibility into constraints and automatically adjusting schedules to hit delivery promises.

By improving schedule reliability, clients typically achieve:

-

- 15–30% boost in OTD performance.

-

- Fewer emergency orders and penalties.

-

- Stronger customer trust, which translates into repeat business and longer contracts.

One of my automotive clients even used their improved OTD as a competitive differentiator during vendor audits, and won more Tier 1 contracts because of it.

How to Calculate ROI from APS Investment

To calculate ROI, I help clients take a holistic view, including both hard benefits (cost savings, reduced inventory, higher output) and soft benefits (improved decision-making, customer satisfaction, and morale).

A simplified APS ROI formula I use is:

ROI (%) = [(Annual Benefits – Annual Costs) / Annual Costs] × 100

Where:

-

- Annual Benefits include labor savings, fewer overtime hours, reduced stock holding costs, and increased revenue from higher throughput.

-

- Annual Costs include software licensing, implementation services, training, and internal project time.

In most implementations I’ve led, clients achieve ROI within 12 to 24 months, sometimes sooner if the pain points were acute (e.g., chronic late deliveries or high WIP).

Tips on Monitoring Benefits and Continuous Optimization

APS is not a “set it and forget it” tool, it’s a continuous improvement enabler. Once the system is live, I encourage clients to:

-

- Establish a dashboard of key KPIs such as OTD, inventory turns, scheduling adherence, and labor utilization.

-

- Schedule regular post-go-live reviews to identify new optimization opportunities.

-

- Encourage planners and supervisors to feed back into the APS logic, refining constraints, buffers, and rules as conditions evolve.

-

- Benchmark performance quarter over quarter, not just pre vs. post go-live.

I’ve seen the most value come from companies that treat APS as a strategic capability, not just software. They build internal champions, invest in ongoing training, and iterate their planning models continuously.

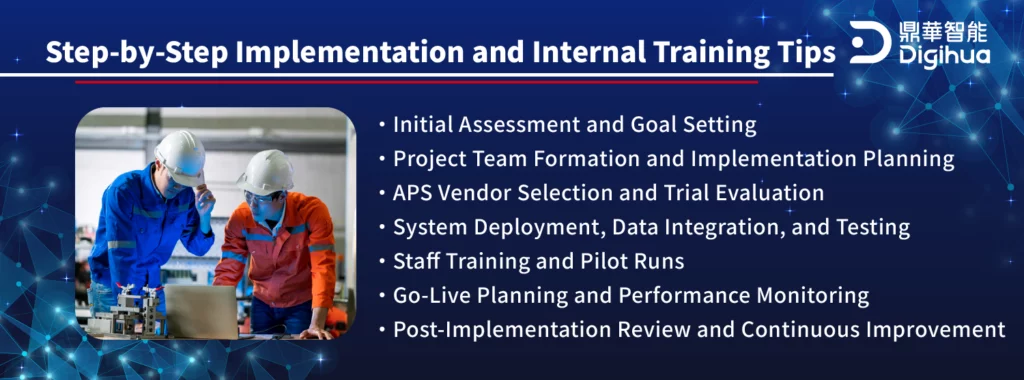

Step-by-Step Implementation and Internal Training Tips

As someone who has overseen dozens of APS rollouts across various industries, I can confidently say this: a well-planned implementation process is the key difference between success and failure. Many companies dive into Advanced Planning and Scheduling hoping for quick results, but without structured preparation, even the best software can underperform. In this section, I’ll outline the step-by-step approach I use to guide clients through a smooth and effective APS deployment, including practical training strategies for internal teams.

Initial Assessment and Goal Setting

Every successful APS project starts with a deep understanding of current operations. In my initial workshops, I work with clients to identify:

-

- Existing scheduling bottlenecks and inefficiencies.

-

- Manual processes that could benefit from automation.

-

- Key business KPIs (like OTD, inventory turnover, or machine utilization).

We then define clear, measurable objectives for the APS system, whether it’s reducing planning time, increasing output, or improving order accuracy. These goals will later serve as benchmarks to evaluate the return on investment and system success.

Project Team Formation and Implementation Planning

Next, I help assemble a cross-functional implementation team. This typically includes:

-

- A project manager (internal or external).

-

- Representatives from production, IT, planning, procurement, and quality.

-

- A senior executive sponsor to ensure alignment and authority.

Together, we define the implementation scope, timeline, budget, and success criteria. I also recommend setting up regular steering committee meetings to keep progress visible and ensure decisions can be made quickly when needed.

APS Vendor Selection and Trial Evaluation

Choosing the right APS vendor is critical. I often advise clients to shortlist two or three vendors based on:

-

- Industry fit (e.g., discrete vs. process manufacturing).

-

- Interface capabilities with existing ERP/MES systems.

-

- Availability of localized support and proven case studies.

We usually conduct vendor demos and trial evaluations, using real production scenarios. This allows key users to test usability, logic accuracy, and reporting functions before committing to a full-scale deployment.

System Deployment, Data Integration, and Testing

Once the software is selected, the next step is data integration, a phase that often reveals hidden inconsistencies in the company’s existing databases. I guide clients through:

-

- Importing and validating master data (BOMs, routings, calendars).

-

- Setting up APIs or middleware to connect with ERP and MES.

-

- Running test simulations to confirm that schedules reflect real-world constraints.

I recommend a staged deployment, starting with a single production line or product family before expanding plant-wide.

Staff Training and Pilot Runs

Even the best APS system is only as effective as its users. That’s why I place heavy emphasis on hands-on staff training. This includes:

-

- Role-based sessions for planners, supervisors, and operators.

-

- Practical scenario testing using company-specific data.

-

- Teaching not just how to use the software, but how to interpret and act on the results.

We also conduct pilot runs, short planning cycles that simulate a real environment while allowing room for adjustment. This is when users gain confidence, and the implementation team can fine-tune system logic.

Go-Live Planning and Performance Monitoring

Go-live is not a single day, it’s a transition phase. I help clients develop a detailed go-live checklist that includes:

-

- Final data validation and system backups.

-

- Communication plans for internal teams.

-

- Contingency measures in case of unexpected disruptions.

During the first few weeks, we closely monitor performance against baseline KPIs. Having daily debriefs with planners and weekly management reports helps identify immediate issues and track early wins.

Post-Implementation Review and Continuous Improvement

After go-live, I conduct a post-implementation review to assess what worked well and what needs improvement. This review includes:

-

- Comparing projected KPIs to actual outcomes.

-

- Gathering user feedback to refine system logic and usability.

-

- Updating training materials and SOPs based on lessons learned.

I also encourage companies to treat APS as a continuous improvement platform. That means revisiting parameters regularly, experimenting with advanced features like AI-based prediction, and expanding usage to other departments like maintenance or logistics.

In my experience, companies that take this iterative approach not only sustain their gains, they compound them over time, evolving into truly agile and data-driven manufacturers.

About Advanced Planning and Scheduling (APS) :FAQ

What is Advanced Planning and Scheduling (APS)?

Advanced Planning and Scheduling (APS) is a digital solution that helps manufacturers optimize production planning, resource allocation, and scheduling. It considers multiple constraints—such as machine capacity, workforce availability, and material supply—to generate the most efficient production plan possible. Unlike traditional ERP systems, APS focuses on dynamic, real-time scheduling and scenario simulation.

How does APS differ from ERP or MES systems?

While ERP (Enterprise Resource Planning) handles business-wide data such as finance, purchasing, and inventory, APS focuses specifically on production optimization.

MES (Manufacturing Execution System), on the other hand, executes and monitors shop floor activities.

In short:

-

ERP = What you plan to produce and purchase.

-

APS = How to schedule it most efficiently.

-

MES = What actually happens on the shop floor.

Together, these three systems create a closed-loop manufacturing ecosystem.

What are the main functions of an APS system?

A robust APS solution typically includes:

-

Demand Forecasting and Capacity Planning: Aligning production capacity with sales forecasts.

-

Finite Scheduling: Generating optimal schedules that consider resource constraints.

-

What-if Simulations: Evaluating alternative plans to respond quickly to disruptions.

-

Order Prioritization: Ensuring high-value or urgent orders are delivered on time.

-

Integration with ERP/MES: Seamless data flow for end-to-end visibility.

What industries benefit most from APS?

APS is widely used in:

-

Automotive and aerospace manufacturing

-

Electronics and semiconductor production

-

Food and beverage processing

-

Pharmaceutical and chemical industries

-

Precision machinery and component manufacturing

Any business that needs to manage complex, multi-step production workflows with limited resources can benefit from APS implementation.

What problems does APS solve?

APS helps manufacturers address common challenges such as:

-

Long lead times and frequent production delays

-

Inefficient resource utilization

-

Bottlenecks caused by unbalanced workloads

-

Poor visibility into production capacity

-

Manual planning errors and lack of flexibility in responding to changes

By digitizing and automating scheduling, APS ensures higher throughput, shorter delivery times, and improved on-time delivery rates.

How does APS improve production efficiency?

APS enables real-time decision-making and data-driven scheduling.

By analyzing constraints (e.g., machine downtime, material shortages), it automatically adjusts schedules to maintain productivity. The result: less idle time, fewer changeovers, and smoother coordination across departments.

How is APS implemented in a factory environment?

Implementation generally follows these steps:

-

Process Assessment: Identify pain points and goals.

-

Data Integration: Connect APS with ERP and MES systems.

-

Model Configuration: Define production rules, capacities, and constraints.

-

Pilot and Training: Test with a limited scope before full deployment.

-

Continuous Optimization: Monitor KPIs and refine scheduling algorithms.

Can APS be integrated with existing systems?

Yes. Most modern APS solutions are designed to integrate seamlessly with ERP, MES, and SCM systems using APIs or middleware. This integration ensures real-time synchronization of production orders, inventory levels, and material availability.

What are the measurable results after implementing APS?

Companies that adopt APS typically see:

-

15–30% reduction in lead times

-

20–40% improvement in equipment utilization

-

Up to 25% increase in on-time delivery rates

-

Better visibility and faster response to production changes

These results vary depending on industry type, data quality, and system configuration.

What factors should be considered before selecting an APS vendor?

When evaluating APS providers, consider:

-

Industry specialization: Does the vendor understand your production model?

-

Integration capability: Can it connect smoothly with ERP and MES systems?

-

Scalability: Can it grow with your business?

-

User interface and training support: Is it intuitive and well-supported?

-

ROI and total cost of ownership: Evaluate beyond the license fee—include maintenance, customization, and training.

Is cloud-based APS better than on-premise solutions?

Cloud-based APS offers faster deployment, scalability, and lower IT maintenance costs. However, on-premise solutions may be preferred for manufacturers with strict data security or network reliability concerns. Many vendors now offer hybrid models combining both advantages.

How long does it take to see results from APS implementation?

Most manufacturers notice improvements within 3 to 6 months after go-live, depending on project scope and data readiness. Full ROI is often achieved within 12 to 18 months when paired with continuous improvement and staff training.

What are some well-known APS software providers?

Some global APS vendors include:

-

Siemens Opcenter APS

-

AspenTech aspenONE Planning and Scheduling

-

DELMIA Quintiq (Dassault Systèmes)

-

Plex Systems APS

-

DigiHua APS (for integrated MES and smart factory applications in Asia-Pacific)

Each platform has unique strengths—such as advanced analytics, cloud integration, or AI-driven scheduling—so it’s crucial to match the tool to your manufacturing needs.

Digihua:Your Expert in Advanced Planning and Scheduling System Solutions

Core Strengths of Digihua Intelligent

Extensive Industry Experience

Since its establishment, Digihua Intelligent has focused on the development and application of production scheduling and manufacturing execution systems. With over 2,000 discrete manufacturing enterprises served, including sectors such as semiconductors, electronic assembly, and plastic injection molding, the company has accumulated a wealth of hands-on experience.

Comprehensive Smart Manufacturing Solutions

Digihua Intelligent offers a full suite of smart manufacturing solutions, including APS (Advanced Planning and Scheduling), MES (Manufacturing Execution System), and QMS (Quality Management System). These solutions are further enhanced with IIoT (Industrial Internet of Things) technologies to enable fully digitized management from planning to execution.

A Key Partner in Digital Transformation

Amid the wave of digital transformation, Digihua Intelligent is committed to being a strategic partner for enterprises. The company provides end-to-end services, from consulting and system implementation to ongoing maintenance, supporting businesses in their journey toward smart manufacturing.

By choosing Digihua Intelligent’s APS solutions, companies can not only enhance production efficiency but also stand out in today’s competitive market, achieving long-term sustainability.

For more information, please visit the official website:https://www.digihua.com.tw/

?A-Comprehensive-Guide-1024x576.webp)