What Is a Manufacturing Execution System (MES)?

If you’ve ever tried to juggle a dozen things at once on a factory floor, keeping an eye on quality, tracking materials, managing orders, and ensuring everything ships on time, you’ll understand why a Manufacturing Execution System (MES) feels like a godsend.

In plain terms, MES is the digital backbone of modern manufacturing, bridging the gap between business planning and shop-floor reality. It’s the system that helps factories “see, decide, and act” in real time.

Definition and Core Functions of MES (Based on the MESA-11 Model)

At its heart, a Manufacturing Execution System is designed to manage, monitor, and synchronize all the processes happening in a production environment. According to the well-known MESA-11 model, MES encompasses eleven core functions, think of them as the “vital organs” that keep a factory alive and responsive.

These include real-time monitoring, traceability, quality control, resource allocation, document management, performance analysis, maintenance scheduling, and labor tracking, among others.

In simple terms, MES keeps tabs on every nut and bolt moving through your plant. It tells you what is being made, how it’s being made, when it’s due, and whether it meets quality expectations.

Imagine a conductor leading an orchestra: the violins (production lines), drums (maintenance teams), and flutes (quality inspectors) all have to stay in sync. MES is that conductor, ensuring every section hits the right note, no delays, no mix-ups, no missing beats.

By collecting data directly from machines and operators, MES delivers real-time visibility into performance metrics. If a bottleneck forms or a batch fails quality checks, managers can act immediately rather than waiting for end-of-day reports. That’s the difference between firefighting and foresight.

MES as the Bridge Between ERP and the Shop Floor

Think of ERP (Enterprise Resource Planning) as the “brain” of the organization, it plans, forecasts, and allocates resources. Meanwhile, the shop floor systems like SCADA or PLC are the “hands” executing the work. The MES sits perfectly in between, acting as the bridge that connects the strategic brain with the operational hands.

Without MES, communication between ERP and production often feels like a game of broken telephone, delays, misunderstandings, and outdated data. With MES in place, the information flow becomes seamless and instant.

For example, when an ERP system schedules a production order, MES translates that plan into actionable instructions for machines and operators. It then reports back on progress, how much is completed, how efficiently, and whether any issues have occurred. That feedback loop allows businesses to adapt plans in real time.

In other words, MES turns business intent into manufacturing reality. It closes the gap between what you think is happening on the floor and what’s actually happening.

This integration empowers decision-makers to fine-tune everything from production scheduling to inventory control, eliminating blind spots that cost time and money.

The Role of MES in the Era of Smart Factories and IIoT

Fast-forward to today’s Industry 4.0 landscape, and MES is no longer just a data recorder, it’s becoming the nervous system of the smart factory.

With the rise of the Industrial Internet of Things (IIoT), artificial intelligence, and cloud computing, MES has evolved into a more dynamic, predictive, and collaborative platform.

Machines equipped with sensors continuously send performance data to the MES. AI algorithms analyze that data to forecast maintenance needs, predict quality deviations, or even auto-adjust production parameters. Cloud-based MES solutions allow global manufacturers to monitor multiple plants across continents as easily as checking a weather app.

Here’s where it gets exciting: MES is now a key enabler of digital transformation in manufacturing. It doesn’t just connect machines, it connects people, data, and decisions.

From predictive analytics that reduce downtime to digital twins that simulate production scenarios, MES brings intelligence and agility to the shop floor.

In short, MES has transformed from a “manufacturing watchdog” into a strategic partner for innovation.

It helps companies adapt to fast-changing markets, meet sustainability goals, and deliver higher product quality at lower cost, all while keeping operations transparent and data-driven.

Why Global Manufacturers Should Adopt MES

If there’s one thing I’ve learned after walking through hundreds of factory floors, from automotive plants in Detroit to electronics lines in Taiwan, it’s this: efficiency loves visibility. And that’s exactly what a Manufacturing Execution System (MES) brings to the table.

Adopting MES isn’t just about “going digital”; it’s about unlocking the full potential of your production ecosystem. Let’s break down the key reasons why global manufacturers are making MES the centerpiece of their digital transformation strategy.

Enhancing Quality and Product Traceability

In a world where a single defective batch can trigger a multimillion-dollar recall, quality and traceability aren’t optional, they’re existential.

A well-implemented MES acts like a digital DNA recorder, capturing every piece of data throughout the production lifecycle, from raw material intake to final inspection.

Imagine being able to trace every screw, solder joint, or bottle cap back to its origin with a few clicks. That’s what MES enables.

It collects real-time quality data directly from machines, sensors, and operators, ensuring that every product meets strict industry standards and regulatory requirements (think FDA, ISO, or automotive PPAP).

When an anomaly occurs, MES doesn’t just sound the alarm, it shows you where, when, and why it happened. This kind of instant visibility turns quality management from a reactive firefight into a proactive safeguard.

In short, MES doesn’t just help you meet compliance, it helps you build customer trust, one traceable product at a time.

Boosting Equipment Efficiency and Reducing Downtime

Every manufacturer dreads the same enemy: unplanned downtime.Machines sitting idle don’t just lose production, they bleed money by the minute. MES tackles this challenge head-on through data-driven scheduling and predictive maintenance.

Here’s how it works: MES constantly collects operational data, temperature, vibration, cycle times, and uses analytics to detect early signs of wear or inefficiency.

Instead of waiting for a machine to fail, maintenance teams get alerts before something breaks. It’s like your car’s dashboard warning you before the engine light turns on.

This proactive approach leads to a significant boost in Overall Equipment Effectiveness (OEE), a key performance metric that combines availability, performance, and quality.

When machines run smoother, operators stay focused, and workflows stay predictable, your production line stops being a roller coaster and starts feeling like a bullet train, fast, stable, and right on time.

Reducing Inventory and Lead Time

Let’s be honest, most factories carry more inventory than they need, just to “play it safe.”

But those buffer stocks tie up cash, occupy space, and hide inefficiencies. MES flips that logic on its head by giving manufacturers real-time visibility into Work-in-Progress (WIP).

When you know exactly what’s happening on every production line, what’s completed, what’s delayed, and what’s next, you can fine-tune scheduling and material flow.

That means less waiting, fewer bottlenecks, and shorter lead times.

In one of the factories I visited, MES implementation cut average WIP inventory by 30% within six months. Orders that once took 10 days were shipping in 7, without any overtime or extra staff.

That’s the kind of lean agility today’s markets demand: faster response times without sacrificing quality.

Simply put, MES helps manufacturers move from “just-in-case” production to “just-in-time” precision.

Achieving a Paperless Shop Floor

If you’ve ever seen a production supervisor flip through dog-eared binders or scribble notes on greasy clipboards, you know how chaotic paper-based processes can be.

MES transforms that chaos into clarity through fully digital, paperless workflows.

Instead of paper work orders, operators receive digital instructions directly on terminals or tablets. Inspection results, process parameters, and production updates are recorded automatically and stored securely in the MES database.

The result? Zero transcription errors, instant data sharing, and real-time transparency across the entire plant.

Going paperless isn’t just about saving trees, it’s about empowering people. Operators can access the latest revisions instantly, supervisors can monitor progress live, and managers can make data-backed decisions without waiting for daily reports.

In a digital factory, paper belongs in the recycling bin, not in your workflow.

Key Considerations Before Selecting an MES Solution

Choosing the right Manufacturing Execution System (MES) isn’t as simple as picking software off a shelf. It’s more like selecting a new engine for your factory, the decision shapes how fast, how efficiently, and how intelligently your entire operation will run.

Over the years, I’ve seen companies rush into MES adoption without a clear plan, only to end up with systems that don’t scale, can’t talk to existing equipment, or fail to meet compliance standards. So before signing that purchase order, let’s walk through a few critical factors you should consider.

Cloud vs. On-Premise Deployment:Which Is Right for You?

This is one of the first big crossroads in any MES journey: Do you go cloud, or stay on-premise?

Think of cloud-based MES as leasing a high-tech condo, flexible, quick to move into, and easy to upgrade. It offers scalability, lower upfront costs, and remote accessibility, perfect for global manufacturers managing multiple plants.

Updates roll out automatically, and cloud architecture supports AI-driven analytics and IIoT integration without heavy infrastructure investment.

On the other hand, on-premise MES is like owning your own house, higher initial cost, but full control. You decide how data is stored, how systems integrate, and when updates happen.

For highly regulated industries like pharmaceuticals, aerospace, or defense, where data sovereignty and security are non-negotiable, on-premise deployments still make a lot of sense.

In reality, many modern manufacturers are choosing hybrid models, blending the agility of cloud computing with the control of on-premise systems. The key is to evaluate your IT maturity, regulatory environment, and long-term scalability goals before committing.

Because once your MES is in place, migrating platforms can feel like changing the foundation of a building while you’re still living inside it.

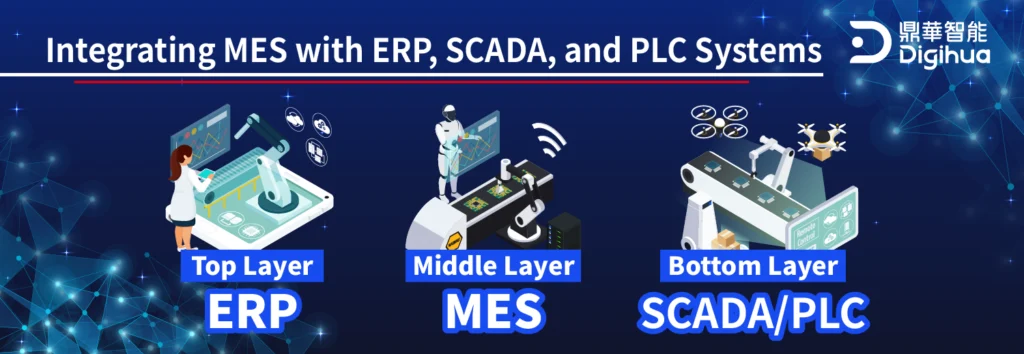

Integrating MES with ERP, SCADA, and PLC Systems

Here’s the truth: an MES doesn’t live in isolation. To unleash its full potential, it must act as a data bridge across your digital ecosystem, from business planning systems like ERP to automation layers like SCADA and PLC.

In technical terms, this integration involves multiple layers:

- Top Layer (ERP):Handles business-level planning, scheduling, and inventory. MES pulls order data from ERP and reports production results back in real time.

- Middle Layer (MES):Translates business goals into actionable shop-floor commands, essentially the “translator” between management intent and machine action.

- Bottom Layer (SCADA/PLC):Collects and transmits live process data, temperatures, cycle counts, alarms, back up to MES for analysis and control.

When these layers flow seamlessly, your plant operates like a symphony. The ERP sets the rhythm, MES conducts the performance, and SCADA/PLC instruments play the notes.

Poor integration, however, creates discord, data silos, reporting lags, and duplicated work. That’s why selecting an MES vendor with robust APIs, OPC-UA compliance, and proven integration frameworks is essential. It ensures that every piece of your digital infrastructure speaks the same language.

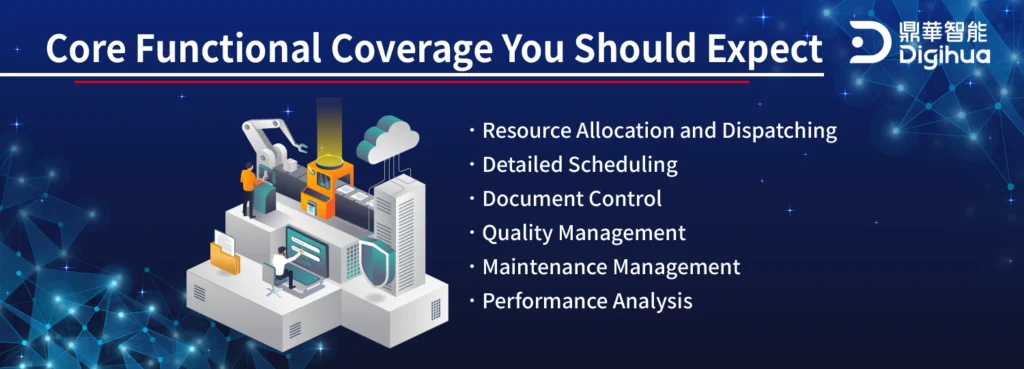

Core Functional Coverage You Should Expect

Every MES promises visibility, but the best ones deliver control.Before finalizing a vendor, make sure the system covers the following core functional areas outlined in the MESA-11 model:

- Resource Allocation and Dispatching:Real-time management of machines, tools, and operators.

- Detailed Scheduling:Dynamic adjustment of production sequences based on priority, capacity, and materials.

- Document Control:Centralized management of SOPs, work instructions, and revision histories.

- Quality Management:In-process inspection, deviation tracking, and SPC (Statistical Process Control).

- Maintenance Management:Preventive and predictive scheduling to reduce downtime.

- Performance Analysis:KPI dashboards for OEE, yield, throughput, and cycle-time insights.

These aren’t “nice-to-have” features, they’re the foundation of what separates a true MES from a glorified data logger.

If your vendor can’t demonstrate real-time dashboards, traceability trails, or flexible workflow engines, it’s a red flag that you’re not getting a full-scale execution system.

Compliance and Traceability Requirements

For manufacturers in regulated industries, compliance isn’t optional, it’s the cost of entry. Whether you’re producing automotive components, pharmaceuticals, or food products, your MES must support complete traceability and auditability at every step.

In automotive, MES ensures compliance with IATF 16949 and PPAP requirements by tracking every part’s serial number and process parameters.

In pharma, it must meet FDA 21 CFR Part 11 by maintaining secure, time-stamped electronic records and e-signatures.

And in food production, it supports HACCP and ISO 22000 through end-to-end batch tracking and recall readiness.

Think of MES as your factory’s “black box recorder.”

If something goes wrong, you can replay the entire production history, who did what, on which machine, at what time, with which materials. That level of digital traceability isn’t just about avoiding fines, it’s about protecting your brand integrity and consumer trust.

Global Implementation Challenges and How to Overcome Them

Rolling out a Manufacturing Execution System (MES) across multiple global sites isn’t like flipping a single switch, it’s more like synchronizing an entire orchestra scattered across continents. Every factory has its own tempo, culture, and operational rhythm.

I’ve seen global manufacturers succeed brilliantly, but I’ve also seen projects stall because they underestimated the complexity of connecting plants from Michigan to Malaysia under one digital umbrella. Let’s break down the most common challenges and how to overcome them strategically.

Multi-Site Operations and Cross-Time-Zone Visibility

When you’re managing multi-site manufacturing, the first question isn’t “Which MES should we choose?”, it’s “How will all our plants talk to each other?”

Centralized MES architectures provide a single source of truth, perfect for executives who want global dashboards showing production performance, inventory status, and OEE in real time. The downside? They require stable connectivity and strong governance to prevent one site’s issue from rippling across others.

In contrast, distributed or site-level MES architectures give each plant more autonomy. Data stays local, allowing sites to operate even if connectivity drops. The trade-off is visibility, it’s harder to maintain consistent reporting and analytics across regions.

The best global implementations often follow a hybrid model: centralized data governance for strategic oversight, with localized MES nodes handling day-to-day execution. This approach keeps every site in tune while giving regional teams the flexibility to adapt to their local tempo.

Time zones, meanwhile, add another layer of complexity. A problem that arises in Europe during the night shift might not reach the U.S. team until hours later.

By integrating MES with global analytics platforms and real-time alerting, you can achieve “follow-the-sun” visibility, where production insights never sleep, even if your teams do.

Language, Localization, and Global Support

If you’ve ever walked into a plant in Mexico where half the team speaks Spanish, the engineers report in English, and the training materials are in German, you know how quickly communication can turn into chaos.

A truly global Manufacturing Execution System (MES) must support multilingual interfaces and localized functionality. Operators need to see machine statuses and work instructions in their native language, not struggle with translations during high-pressure moments.

Localization also goes beyond words. It involves adapting units of measurement, date formats, regulatory templates, and even workflow logic to fit regional expectations.

For example, what counts as a “batch” in an American food plant might differ from how a Japanese facility defines it.

Then there’s technical support, because when production stops, time zones don’t matter. Choosing an MES vendor with regional service partners, multilingual help desks, and global 24/7 support can make or break your rollout.

Remember, software alone doesn’t drive digital transformation, people do. And people need systems that speak their language, both literally and culturally.

Cybersecurity and Data Sovereignty

In the age of connected factories, data is the new gold, and like gold, it needs strong vaults.

Global manufacturers face increasing pressure from data sovereignty laws that dictate where data can be stored and how it must be protected.

For example, the EU’s GDPR requires strict handling of personal and operational data within Europe. China has its own Cybersecurity Law, mandating local data storage. The U.S. and other countries have additional sector-specific regulations, especially for defense and healthcare manufacturing.

So when deploying MES globally, you can’t simply copy-paste your architecture across borders.

You need a data-hosting strategy that respects each region’s laws, whether that means using local data centers, hybrid cloud storage, or private hosting environments.

Cybersecurity must also be baked in from day one. That includes:

- End-to-end encryption for data in motion and at rest

- Role-based access control (RBAC) to protect sensitive production data

- Continuous monitoring and intrusion detection systems to guard against attacks

Think of MES as your digital nervous system, if it’s compromised, the entire body feels it. A secure, compliant architecture ensures your operations stay both agile and protected.

Standardization vs. Customization Across Plants

One of the biggest philosophical debates in global MES deployment is this:

How much should we standardize, and how much should we localize?

Standardization brings consistency, efficiency, and easier maintenance. Corporate headquarters love it because global reports look clean, processes align, and audits are smoother. But the danger is rigidity, forcing a cookie-cutter process onto every plant can crush innovation and local efficiency.

On the other hand, customization allows plants to adapt workflows to their unique machines, products, or compliance needs. The risk? It creates fragmented systems that are hard to manage and upgrade, like having a family of cousins who all speak slightly different dialects.

The ideal balance lies in what I call “controlled flexibility.” You establish global templates, standardized data models, dashboards, and reporting structures, but allow local configuration for line-specific processes, quality rules, and scheduling nuances.

In practice, this means defining which processes are mandatory across all sites and which ones can be tuned regionally. A well-architected MES should make this modular design possible without heavy coding.

When done right, standardization and customization stop being opposing forces, they become two hands working together to shape a global yet agile manufacturing network.

MES Implementation Roadmap and Success Factors

Implementing a Manufacturing Execution System (MES) is a bit like building a bridge while traffic is still moving, it demands precision, coordination, and clear communication. Over the years, I’ve seen factories transform from chaotic data silos into synchronized digital ecosystems, but that transformation doesn’t happen by accident.

To make MES work for your organization, you need both a solid roadmap and the right mindset. Here’s how to make the journey smooth and how to steer clear of the common traps along the way.

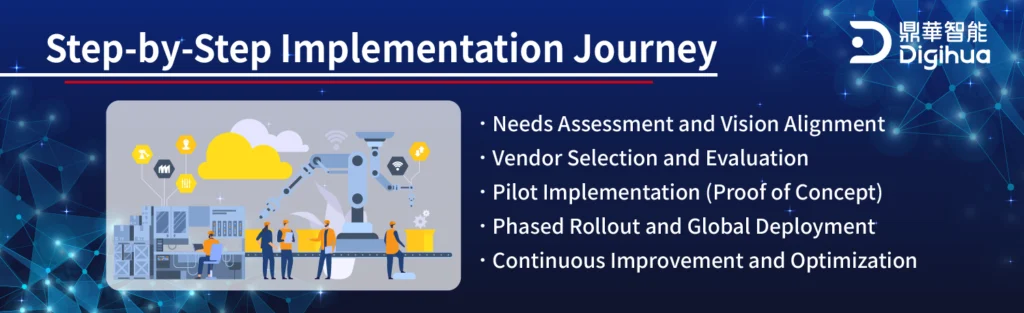

Step-by-Step Implementation Journey

Rolling out an MES is not a one-off IT project; it’s a multi-stage transformation that touches every part of your operation. Each step builds on the last, turning strategy into sustained performance improvement.

- Needs Assessment and Vision Alignment

Start by identifying your pain points and defining what success looks like. Is the goal better traceability? Reduced downtime? Standardized global reporting?

Without a clear vision, MES can quickly become a tech project rather than a business enabler.During this stage, involve both executives and operators, because the people using the system daily often spot the blind spots the boardroom can’t.

- Vendor Selection and Evaluation

Once your requirements are clear, evaluate vendors based on functional coverage, integration capabilities, and industry experience. Don’t just rely on demos, request references and visit live customer sites if possible.

You’ll learn more from a single day on a real shop floor than a dozen PowerPoint slides.Remember, you’re not just buying software; you’re choosing a long-term partner.

- Pilot Implementation (Proof of Concept)

Start small. A pilot in one plant or production line allows you to validate assumptions, test integrations, and collect measurable ROI data. Treat it as a sandbox for learning.

A successful pilot gives you internal champions, people who can vouch for MES benefits when it’s time to scale.

- Phased Rollout and Global Deployment

Once the pilot proves its worth, scale gradually. Use lessons learned to fine-tune templates, workflows, and training materials before deploying across regions.

Rolling out MES globally is like conducting a relay race, each site must be ready to grab the baton before the next one runs.

- Continuous Improvement and Optimization

Implementation doesn’t end at go-live. MES provides a constant stream of operational data, gold dust for ongoing optimization.

Regularly review dashboards, adjust KPIs, and integrate new technologies like AI or predictive analytics. The best manufacturers treat MES as a living system, not a static tool.

Five Critical Success Factors

From my experience, the difference between MES success and failure often comes down to five simple, but powerful, ingredients.

- Executive Buy-In and Leadership Commitment

Without top-down support, MES initiatives tend to lose momentum halfway through. Executives must not only fund the project but also communicate its strategic importance company-wide.

- Cross-Functional Collaboration

MES touches production, quality, IT, logistics, and maintenance, so siloed thinking won’t work. Establish a core project team with representatives from each department to ensure every perspective is heard.

- Clean and Structured Data

MES is only as smart as the data it receives. Inaccurate master data or inconsistent naming conventions can derail automation. Before implementation, invest time in data cleansing, think of it as laying a clean foundation before pouring the concrete.

- Comprehensive Staff Training

Even the most advanced MES is useless if people don’t know how to use it effectively. Train operators, supervisors, and IT support staff early and continuously. Make training practical, hands-on sessions resonate far more than manuals ever could.

- Change Management and Cultural Adoption

This one’s often overlooked. Introducing MES means changing how people work, and change can trigger resistance.

Communicate early, explain the “why,” and celebrate quick wins. When employees see how MES makes their jobs easier (not harder), adoption skyrockets.

When all five of these factors align, MES stops being “just software” and becomes a strategic enabler that reshapes how your organization thinks, operates, and competes.

Common Pitfalls to Avoid

MES implementations don’t fail because the technology is bad, they fail because execution slips. I’ve seen it happen to the best of teams. Here are the pitfalls to watch for (and how to sidestep them):

- Undefined KPIs and Success Metrics

If you can’t measure success, you can’t manage it. Define clear KPIs before you begin, like OEE improvement, scrap reduction, or cycle time cuts, and track them relentlessly.

- Integration Issues Between Systems

MES thrives on connectivity. Gaps between MES, ERP, and SCADA systems lead to manual data entry and frustration. Validate all integrations early in the pilot phase, not during rollout.

- Resistance to Change

The human factor can make or break MES. Some operators may see MES as surveillance rather than support. Counter this by highlighting benefits, reduced rework, fewer errors, and more control over their daily operations.

- Inconsistent Processes Across Sites

Standardize your workflows before automation. If each plant uses different definitions for “shift,” “lot,” or “downtime,” your MES will spend more time reconciling differences than delivering insights.

- Poor Data Visibility and Reporting

MES is meant to turn data into decisions. If dashboards are unclear or reports arrive too late, users stop trusting the system. Focus on real-time dashboards that make information actionable, not just visual.

Avoiding these pitfalls isn’t about perfection, it’s about anticipation. A good MES project anticipates where friction will occur and designs around it.Think of it like building a race car: you can’t eliminate friction, but you can engineer how it’s managed.

Next Steps for Manufacturers Planning to Adopt MES

After seeing how Manufacturing Execution Systems (MES) transform factories around the world, I’ve noticed one constant truth: success begins long before the first server is installed or the first dashboard goes live. It starts with preparation and strategic clarity.

If you’re considering adopting MES, here’s how to set your organization up for a smooth transition, and long-term digital success.

Conducting an Internal Readiness Assessment

Before you even start talking to vendors, take an honest look inside your factory walls. MES doesn’t magically fix bad data, inconsistent processes, or unclear goals. The first step is to evaluate your organizational readiness.

Ask yourself:

- What are our biggest production pain points today, downtime, quality, or scheduling?

- How mature is our data infrastructure? Are we still tracking KPIs in spreadsheets or already using connected systems?

- Does our leadership team see MES as an IT project or a business transformation initiative?

An internal readiness assessment gives you a clear baseline. It also helps you prioritize, because MES can do a hundred things, but you need to start with the ten that matter most to your business goals.

Think of it like remodeling a house: you don’t start by buying furniture; you start by checking the foundation.

Selecting the Right MES Vendor or Implementation Partner

Choosing the right MES partner can make or break your project. Over the years, I’ve seen companies succeed not because they picked the biggest vendor, but because they picked the right fit, a partner who understood their industry and could scale with them.

Here are four criteria that should top your list:

- Global Support Footprint: If you operate across multiple regions, you need a vendor with localized service teams and multilingual support.

- Integration Expertise: The best MES vendors are those who can seamlessly connect ERP, SCADA, and shop-floor systems, not just install software.

- Industry Specialization: Each industry has unique needs. Automotive MES focuses on traceability; electronics MES emphasizes high-mix scheduling; pharma MES demands compliance. Pick a partner who speaks your language.

- Roadmap Stability and Innovation: Ask about the vendor’s long-term product roadmap. Are they investing in AI, cloud, and IIoT capabilities? You want a platform that grows with you, not one that becomes obsolete in three years.

When evaluating vendors, think less about “features” and more about partnership. You’re not buying a tool, you’re choosing a co-pilot for your digital manufacturing journey.

Setting Realistic Timelines and Measurable KPIs

MES implementation isn’t a sprint; it’s a marathon with well-defined milestones. The key is to set realistic expectations, both in terms of timeline and measurable results.

For most mid- to large-scale manufacturers, a phased rollout takes 9–18 months, depending on complexity and integration scope. But what really matters is defining KPIs that reflect tangible improvement during the first 12 months:

- OEE (Overall Equipment Effectiveness): Aim for a 10–15% boost through reduced downtime and improved utilization.

- First-Pass Yield: Target fewer defects and rework, even a 5% increase can have a huge financial impact.

- Inventory Reduction: Track work-in-progress (WIP) visibility and buffer stock optimization. A 10% drop is a great early win.

Keep in mind, success metrics should be business-driven, not IT-centric. A beautifully configured MES that doesn’t move your bottom line is just expensive wallpaper.

Building a Long-Term Digital Manufacturing Strategy

Once your MES is up and running, the real journey begins, turning data into foresight.

The smartest manufacturers I’ve worked with don’t stop at implementation; they treat MES as the foundation for continuous digital evolution.

Here’s what that evolution looks like:

- Integrate AI and Predictive Analytics: Use MES data to forecast maintenance, optimize yield, and identify process drift before it happens.

- Adopt Digital Twins: Mirror your physical production lines in a virtual environment to simulate changes before they hit the floor.

- Expand Across the Value Chain: Connect MES with supply-chain planning, quality labs, and customer feedback systems to close the loop.

This is where MES graduates from a control system to a strategic intelligence layer, one that helps you anticipate challenges, not just react to them.

In other words, don’t just “implement MES.” Evolve with it.

Because the factories that win tomorrow won’t just be automated, they’ll be self-optimizing, continuously learning, and globally connected through the digital nervous system that MES makes possible.

Final Thoughts

Adopting MES is one of the most transformative moves a manufacturer can make, but it’s not about chasing buzzwords like “Industry 4.0” or “smart factory.” It’s about building a sustainable ecosystem where data, people, and machines work in harmony.

Start with readiness, choose your partners wisely, measure what matters, and keep an eye on the long game.

If you can do that, your MES journey won’t just modernize your production, it’ll redefine how your organization competes in a connected, data-driven world.

Digihua:Manufacturing Execution System (MES) Expert

Digihua is a professional smart-manufacturing solution provider specializing in Manufacturing Execution Systems (MES) for modern factories. With deep industry experience and on-site process knowledge, digihua helps enterprises connect production data, optimize scheduling, improve quality control, and build transparent, real-time dashboards for shop-floor management.

Digihua solutions integrate seamlessly with ERP, APS, WMS, and equipment data acquisition, enabling factories to reduce downtime, eliminate manual errors, and achieve stable, data-driven operations. From consulting, system deployment, and customization to training and continuous optimization, digihua accelerates digital transformation and supports manufacturers in building highly efficient, smart production environments with stronger competitiveness in global markets.

If you have any Manufacturing Execution System (MES) requirements, please feel free to contact Digihua.

?A-Comprehensive-Guide-1024x576.webp)