The semiconductor industry has reached a critical turning point. As Moore’s Law slows and challenges in advanced nodes escalate, market demands for reliability and efficiency remain unforgiving. The traditional manufacturing model—built on human experience, manual labor, and rigid discipline—can no longer sustain such immense pressure.

Against this backdrop, DigiHua re-examined the dual pillars of wafer fabrication and packaging/testing. We realized the core issue isn’t a single process or machine, but the entire process chain, which has become too complex, too precise, and overly reliant on “unquantifiable human experience.” Any microscopic variance today could become a fatal failure for a module three months down the line.

This is why smart manufacturing is no longer a “nice-to-have” tool, but the only viable solution for the semiconductor industry to move forward. From data collection to anomaly prediction, and from yield enhancement to autonomous decision-making, AI-driven systems are no longer just assisting engineers—they are transforming entire factories into a “process brain” capable of continuous learning and evolution.

In the following sections, we will address the actual pain points of the production line, demonstrating how smart manufacturing systems systematically reshape semiconductor competitiveness—from low-level equipment parameters to final module reliability.

Summary

Many veterans with over 20 years on the fab floor share the same observation: today’s bottleneck for yield is no longer a specific machine or a single step, but rather a “butterfly effect” chain reaction across processes. A minor deviation in the front-end may only surface during module testing three months later; yet, we are still relying on paper logs and Excel comparisons to hunt for clues. This inefficient traceability is equivalent to surrendering control over your yield.

Consequently, our core philosophy in driving the DigiHua iMES smart manufacturing system is clear: it is not about digitizing existing workflows, but about making the entire front-end and back-end process truly “visible,” “connected,” and “predictable.”

- Data traceability is not just a record; it is a weapon.

- Process control no longer relies solely on the memory of senior engineers.

- Flexible manufacturing capabilities are evolved by AI into a true “decision engine.”

Combining these capabilities, it becomes clear that digital transformation is no longer a slogan—it is the watershed moment that determines whether a semiconductor fab can survive the next decade.

Table of Contents

- 1. Understanding Wafer Fabrication in Three Minutes

- 2. Deep Analysis: Front-end vs. Back-end Directions

- 3. Why Manufacturing Relies on Smart Systems

- 4. Process Management via Production, Quality, and Equipment Control

- 5. Why Choose DigiHua iMES: Comparison & Strategy

- 6. FAQ: ROI, AI Implementation, and Data Security

1. Understanding Semiconductor Wafer Fabrication in Three Minutes

What is semiconductor wafer fabrication? Do you think chipmaking is simply “putting circuits into silicon”? In reality, it’s more like quietly constructing a “microscopic electronic empire,” invisible to the naked eye, atop a seemingly plain gray wafer.

For most, the term “wafer fabrication” either draws a blank or evokes a sense of daunting complexity. But you might not realize that every wafer produced is a feat of defiance—taking an abstract blueprint from an engineer’s mind and transforming it into a physical structure that remains stable under high voltage and heavy current, ultimately mastering the flow of energy.

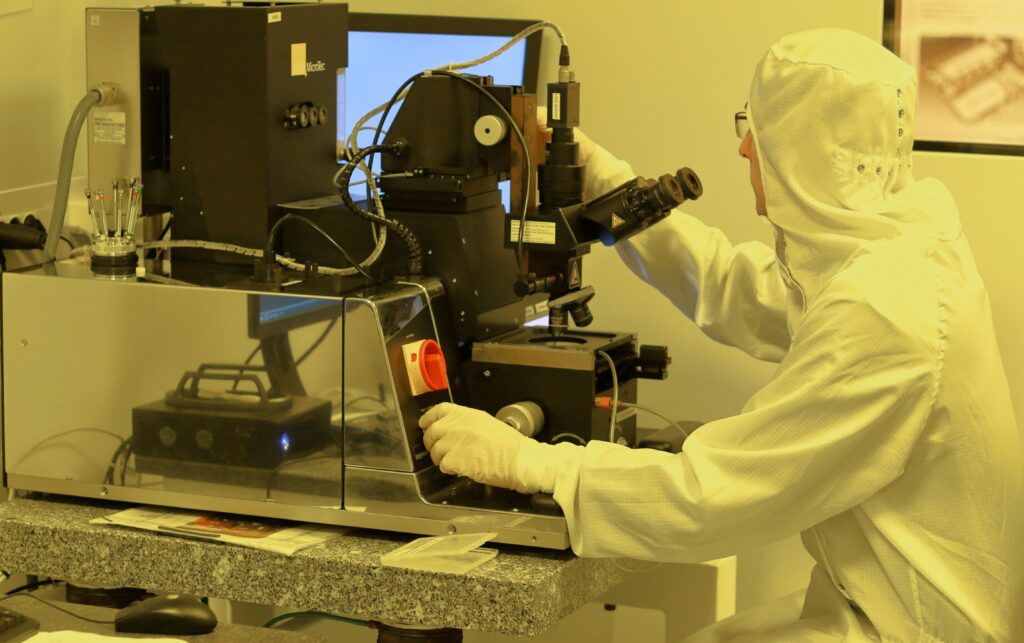

This is how all modern electronic components are born. The tech world loves to discuss applications, end-products, and nanometer specs, but what truly determines the performance ceiling of these products is hidden within five often-overlooked key actions of front-end wafer processing.

If your first reaction is just seeing a wafer, your insight should be understanding how it evolves from a piece of “land” into a multi-layered, strictly controlled “skyscraper.” The five major steps of the wafer process are the methods used to transform abstract logic into concrete electrical properties.

The Five Key Steps of Wafer Fabrication

Step 1: Surface Cleaning and Layering the Foundation

It doesn’t start with manufacturing, but with cleaning it until it’s “pristine beyond human habitation.” A nanometer-sized dust particle on a wafer is like a boulder in a skyscraper’s foundation—everything follows will be skewed. First, we clean the wafer to a flawless state and begin “laying the foundation.” Through deposition, oxidation, and sputtering, we stack layers thinner than a human hair onto the silicon.

Step 2: Blueprints Aren’t Drawn; They Are “Projected”

Photolithography is akin to magic. Engineers coat the wafer with photoresist, then use EUV/DUV lithography machines to “project” the circuit blueprint directly onto the surface. The circuitry is scaled down to an insane degree. An alignment error of just 1 nanometer? Sorry, that entire layer is scrapped.

Step 3: “Carving Out” a Home for Electrons

Lithography only draws the outlines; the actual carving is done by Etching. Using chemicals, plasma, and temperature control, we precisely remove unwanted material. What remains are the paths electrons will travel. Every trench must be as straight as a skyscraper’s pillars; a slight tilt could cause the entire circuit to fail.

Step 4: “Injecting” Electrical Properties to Create a High-Voltage Soul

Once built, the structure is just an empty shell. To bring it to life, we use Doping—firing impurity atoms like bullets into the silicon at high energy. This determines if the component is P-type or N-type. High-power components, in particular, must reliably withstand violent shocks of thousands of volts. Engineers even use electron beams to fine-tune crystal lifetime, creating the “high-voltage monsters” you see today.

Step 5: Without This, the Wafer is Just a “Fragile Heart”

With the structure and electrical properties set, the “boundaries” of the chip remain vulnerable under high voltage. Electric fields tend to cluster at the edges, which can lead to breakdown. Therefore, we perform Beveling—shaving the wafer edges to precise angles to disperse the electric field. Without this, high-voltage components wouldn’t survive. Only then is the Front-end process truly complete.

2. In-depth Analysis: Two Strategic Directions of Semiconductor Manufacturing

Many believe that “making a chip” is simply feeding materials into a machine and following a checklist. In reality, the burden on an engineer’s shoulders is far heavier. Semiconductor manufacturing is not a linear path; it is more like three sets of muscles working in unison—comprising front-end, mid-end, and back-end processes.

Whether your component can survive over a decade under extreme current, high temperatures, and long-term stress depends on the coordination of these three “muscles”. If any single link fails, reliability becomes like a kite with a snapped string—never far from crashing.

Front-end: The Foundation and Soul of the Component

The front-end is the starting point and the stage where “mistakes are most expensive”. There is no room for luck here—only control and verification. We pursue nanometer-level precision in lithography not for aesthetics, but to ensure that atoms in the diffusion furnace stay exactly where they belong.

The ultimate goal of the front-end is to manifest the “soul” of the component—shaping electrical structures like the P-N-P-N junction. A mere one-degree variance in furnace temperature uniformity can cause the breakdown voltage to plummet by half. Controlling carrier lifetime, in particular, is akin to performing delicate surgery.

Once the structure is complete, the first step is laying electrodes to allow current to flow. The thickness, uniformity, and contact quality of the metal layers determine conduction loss. If metallization resistance is too high, the chip suffers from a “chronic illness”: overheating, dropping efficiency, and a shortened lifespan.

Next comes the brutal stage of Wafer Probing—it isn’t just a test; it is a judgment. Learning to interpret the Wafer Map is the watershed moment for an engineer’s maturity. Every “red dot” is not an accident; it is a clue pointing back to process drifts in the previous stages.

Back-end: Ensuring Performance Withstands the Test of Time

If the front-end provides performance, the back-end serves as the guarantor of “lifespan” and “durability”. The back-end is not mere assembly; it is the transformation of a good die into a power fortress capable of resisting extreme environments. In this stage, we face two primary adversaries: heat and the stress induced by that heat.

Before entering assembly, back-end engineers must ensure the seamless transfer of data. Every die post-dicing must carry its corresponding Wafer Map and test records. This marks the first instance of true “traceability” in the product lifecycle.

The Real Battle:

- Void Rate in Soldering/Sintering: Voids invisible to the eye will trap heat, forming irreversible hot spots. More voids directly correlate to a shorter operational life.

- Wire Bonding: This isn’t just about “attaching wires”; it’s about enduring thousands of thermal cycles. Poor quality leads to fractures during thermal expansion and contraction—a failure customers never forget.

- Encapsulation and Potting: These determine if the module can resist deformation, short circuits, and structural collapse under years of thermal stress.

Ultimately, Power Cycling Tests bring the quality of every process to light. The value of a back-end engineer lies in ensuring that peak performance lives long and remains stable in the real world.

3. Why Manufacturing Processes Must Rely on Smart Systems

After interviewing over 20 semiconductor fabs, the most memorable stories we gathered weren’t about equipment or parameters, but about people. One executive, a 20-year industry veteran, shared an insight that became the turning point in our understanding of a “smart system’s” true value.

He recalled his early days, learning by physically turning the knobs on diffusion furnaces. Back then, it was all about “feel” and intuition. “Front-end structures had to be flawless. During mid-end testing, we’d take an ink pen and manually mark the defects right on the wafer,” he said calmly. Yet, you could sense that the engineers of that era carried a very rigid internal standard of excellence.

However, after that moment of nostalgia, he added a comment that silenced our team for a few seconds: “Today’s processes cannot be mastered through human effort alone. The limits of human capability have become the bottleneck.”

1. Cross-Process Sensitivity and Traceability Challenges

The real challenge is that a failing module is often the result of a series of microscopic deviations accumulated 3 to 5 months prior. We know a “butterfly effect” exists across processes, but we lack the tools to track the butterfly’s flight path. This frustration of “post-mortem guessing” is the heaviest hidden pain on the production line.

2. High Value, High Risk: Every Mistake Burns Money

The value of a high-power wafer is often several times that of a logic chip. The value of PdM (Predictive Maintenance) and APC (Advanced Process Control) lies in “hitting the brakes before the crash.” APC corrects parameters before deviations escalate—something traditional human judgment simply cannot achieve.

3. Customer Demands for Reliability and Data Transparency

Automotive and energy clients are no longer satisfied with “average yield.” They demand that every single chip be traceable to its specific equipment ID, parameters, and real-time health indicators during production. Achieving “Unit-level Traceability” is impossible with just paper and Excel.

Smart Systems are Not Meant to Replace People

Smart systems actually perform three fundamental roles:

- Turning Veteran Experience into Transferable Assets: By codifying the OCAP (Out of Control Action Plan) and logic of senior engineers into system rules, juniors can avoid 90% of basic errors—not because they are better, but because the system prevents errors from “slipping through.”

- A 24/7 Gatekeeper: The system tirelessly monitors equipment health, signal jitter, and microscopic drift. You will realize that the time cost spent on retrospective tracing is actually far more expensive than upgrading the equipment itself.

- Converting Experience into Data, and Data into Assets: When a system can instantly weave packaging parameters, probe tests, and temperature curves into a complete narrative, you’ll see that the true waste on the production line wasn’t material—it was time.

4. Mastering Front, Mid, and Back-end Processes via Smart Systems

The first step DigiHua took was refocusing on the three segments of the process chain: front-end, mid-end, and back-end. Our goal isn’t to stack features, but to integrate the behaviors, risks, and variables of every process stage into a comprehensive system capable of tracking, predicting, and verifying. This architecture ultimately centers on three pillars: Production Control, Quality Control, and Equipment Control.

1. Data Acquisition and Analysis (DAW & DAA)

At DigiHua, we believe that if records are complete, problems are always traceable. The core lies in achieving true “Unit-level Traceability”:

- Front-end: The pedigree of every die must be crystal clear—including its ID, furnace number, gas flow curves, and temperature distribution. Upon completion of Wafer Probing, each die must carry its “report card”—including the Yield Map and electrical data—to the next stage.

- Back-end: A module serial number represents a complete family history. The system automatically links the die source ID, soldering curves, bonding tension, and thermal resistance data. By overlaying maps, it can instantly connect back-end hotspots to front-end wafer defects to identify root causes.

2. Production Process Control (PCC)

To stabilize yield, one must first stabilize the process. DigiHua transforms “experience” into “executable rules”:

- Front-end: Ultimate Error-Proofing and Verification: After new recipes or maintenance, the system automatically locks subsequent batches until the pilot run passes verification.

- Recover Runcard: This acts as the “memory hub” during unexpected downtime, guiding the next recipe and reducing human error to zero.

- Back-end: The Lifeline and Automated Management: The system strictly limits rework cycles for soldering and bonding; exceeding the limit triggers mandatory scrapping to safeguard customer trust. It also utilizes Yield Map data to automatically exclude defective dies, ensuring every assembly step is data-driven.

3. Production Quality Control (PQC)

Quality control is about “minimizing variation” throughout the entire journey:

- Material Management: Rigid control over photoresist expiry, solder paste thawing time, and silver paste storage—”No compliance, no release”.

- SPC & Early Warning: Monitoring hundreds of key parameters. If deviations hit the “red line,” the system triggers an OCAP (Out of Control Action Plan) to guide immediate action.

- Contamination & Monitor Wafer Control: Automated equipment locking to prevent cross-contamination and monitoring of test wafers to ensure absolute cleanliness.

4. Production Equipment Control (PEC)

There is no healthy process without healthy equipment:

- Chamber Life Management: Tracks chamber contamination levels and predicts cleaning/replacement intervals to defuse hidden process “time bombs”.

- MSA (Measurement System Analysis): Ensures the reliability of probers and testers to prevent “illusionary” data.

- Change Management: All changes (PCRB) must undergo rigorous review, ensuring synchronized updates to documentation and SOPs.

When every process segment is fully recorded and monitored, you realize that yield is not a matter of luck, but of “controllability”. This is the core value of DigiHua’s smart manufacturing.

5. Why Choose DigiHua iMES?

We can no longer allow “human experience” to define the ceiling of high-power semiconductor manufacturing, nor let “data latency” become a bottleneck for yield enhancement. Facing hundreds of sensitive parameters and the exorbitant costs of trial and error from front-end to back-end, we urgently need a “brain” capable of mastering high complexity and uncertainty.

DigiHua’s iMES system serves as the central hub that integrates the process wisdom of veteran engineers with advanced AI algorithms, replacing the inefficient and lagging manual decision-making of traditional manufacturing models.

| Traditional Manufacturing | iMES Core Solutions |

|---|---|

| Lagging perception of dynamic info: Lead time deviation as high as 15%–20%. | ATP/CTP Algorithms: Advanced order review improves plan execution coverage to over 90%. |

| Imbalanced resource allocation: Equipment bottlenecks vs. idle mature processes. | AI Multi-objective Optimization: Balances profit margins and utilization through dynamic allocation. |

| Insufficient material coordination: Frequent production interruptions. | Batch Traceability Algorithms: Links orders to materials and implements substitution rules to reduce scrap. |

| Low anomaly response efficiency: Manual adjustments take hours or even days. | Real-time IIoT Alerts: Auto-retrieves idle equipment, compressing response time to under 10 minutes. |

From Empirical Forecasting to Algorithmic Review

iMES builds forecasting models based on historical orders, industry trends, and policy variables, enabling us to pre-allocate specialized materials and scarce capacity essential for high-power semiconductors. During the Order Review phase, the system uses algorithms to automatically complete three validations:

- Capacity Review: Calculates idle equipment capacity and back-calculates wafer starts based on yield projections.

- Material Review: Checks material kitting rates; if shortages in high-purity chemicals or specialty solders are detected, it triggers procurement alerts and adjusts lead times.

- Process Review: Verifies if high-voltage structures or packaging types match the fab’s technical capabilities.

Flexible Production via Multi-objective Optimization

iMES utilizes AI algorithms to achieve optimal allocation under complex constraints:

- High-value Priority: Prioritizes critical equipment like lithography machines for high-margin orders.

- Resource Vitalization: Simultaneously utilizes idle capacity for mature process products to balance overall profitability.

- Back-end Optimization: Dynamically allocates orders for QFP, BGA, and CoWoS based on equipment load to prevent bottlenecks.

Dynamic Adjustments and Anomaly Response

Leveraging the Industrial Internet of Things (IIoT), the system builds an agile response mechanism:

- Equipment Failure Response: Automatically reallocates orders during equipment failure, compressing adjustment time from 4 hours to just 10 minutes.

- Customer Change Response: Rapidly reviews residual capacity to provide feasible solutions, achieving true flexible manufacturing.

In summary, the value of DigiHua iMES is no longer just simple data logging; it has become the intelligent hub driving production decisions. As our veterans observed: “This smart system is something we should have implemented long ago”.

6. FAQ: Frequently Asked Questions

1. What is the average ROI and payback period for implementing MES in semiconductors?

There is no fixed number for ROI in semiconductor MES, but it is typically remarkably high. The benefits provided by MES reflect directly in financial gains—especially in yield, OEE, and inventory/cycle time. The payback period for most factories falls between 18 to 36 months. If the MES utilizes AI to participate in decision-making, the ROI jumps significantly. It is an investment in a “process brain” for predictable and quantifiable manufacturing.

2. How is AI specifically applied in semiconductor factories?

AI implementation focuses on making decisions smarter and preventing anomalies from spiraling out of control. Key applications include:

- AI Smart Scheduling: Moving away from “veteran intuition” for batch dispatching.

- APC (Advanced Process Control): Using data for fine-tuning instead of relying on “feel”.

- Defect Classification & RCA: Analyzing Wafer Maps automatically without manual overnight shifts.

- PdM (Predictive Maintenance): Turning unexpected downtime into advance notifications.

3. What are the standardization requirements for the data acquisition layer (EAP/FDC)?

The basic infrastructure is SECS/GEM, ensuring data from every tool can be received and parsed in a unified language. The real challenge is “Semanticization”—organizing and tagging sensor signals so AI can effectively learn from the data. Smart manufacturing is built on data engineering where only “understandable” data qualifies as intelligence.

4. How can the long-cycle supply chain (SCM) be optimized?

Optimization requires precise forecasting and total visibility. AI demand forecasting models pre-determine replenishment and procurement risks by integrating historical orders, WIP, and real-time capacity. The core lies in “Capability to Promise” (CTP), which dynamically assesses factory capacity to provide verified delivery dates in seconds.

5. How do you implement Predictive Maintenance (PdM) for equipment?

Factories must move from “time-based maintenance” to a strategy based on the actual status of equipment. By utilizing FDC high-frequency monitoring and machine learning, models detect failure precursors invisible to the human eye. The system alerts maintenance teams to resolve issues before a breakdown occurs, resulting in higher OEE and lower scrap.

6. How do employee skill requirements change after a smart transformation?

Roles shift from “operators” to “decision-makers” and “data managers”. Operators master electronic SOPs and system-driven OCAP operations. Engineers and managers must possess data analysis skills and the ability to interpret AI model results to optimize parameters with IT teams.

7. How is data security and cybersecurity guaranteed?

- Architecture Isolation & Protection: Implementing internal network isolation and Zero Trust architecture for identity verification.

- On-Premise Deployment: Deploying core systems like MES on-premise ensures data remains behind the enterprise firewall, reducing cyberattack risks.

- Supply Chain Management: Rigorous auditing of remote connection channels for suppliers to prevent infiltration attacks.

8. What are the focuses of global semiconductor smart manufacturing?

- USA: Focused on AI modeling and underlying algorithms for advanced nodes like 3nm.

- Taiwan: Focused on production efficiency and yield through powerful MES systems.

- China: Focused on self-controllability and synergy through localized MES and IIoT platforms.

- Europe: Focused on reliability and functional safety for automotive and industrial sectors.

9. How do you minimize impact and risk during implementation?

The principle is a phased, shock-absorbing introduction. Implementation is split into the Data Layer, Control Layer, and Decision Layer. Digital Twins are used to run real processes in virtual environments to catch errors. “Dual-running” ensures consistency before the final cutover.

10. How do applications differ between mature and advanced processes?

- Mature Processes (65nm+): Focus on cost control and OEE enhancement using AI scheduling to achieve economies of scale.

- Advanced Processes (7nm-): Focus on yield and parameter optimization using FDC and APC for real-time adjustments.