Introduction

Digital transformation applies across many industries. For manufacturers, it is a critical step toward smart manufacturing and Industry 4.0.

Amid constant shifts in the global supply chain, many manufacturers have realized that traditional management and tacit, experience-based practices can no longer keep up with market uncertainty. Digital transformation connects data, processes, and decisions in real time, improving overall production efficiency and operational resilience.

However, every factory floor operates differently and faces its own management challenges. As a result, many companies don’t know how to take the first step, how to advance, or even whether they are ready.

This article is written for the manufacturing sector, insisting that digital transformation must be grounded in industry characteristics. Based on a company’s scale and maturity, we outline how to progressively build the foundations of smart manufacturing—guiding you step by step from assessment and tool selection to organizational optimization. The goal is to help you confidently take the first step, and establish the real-time feedback loops and continuous improvement cycles required for Industry 4.0.

Summary

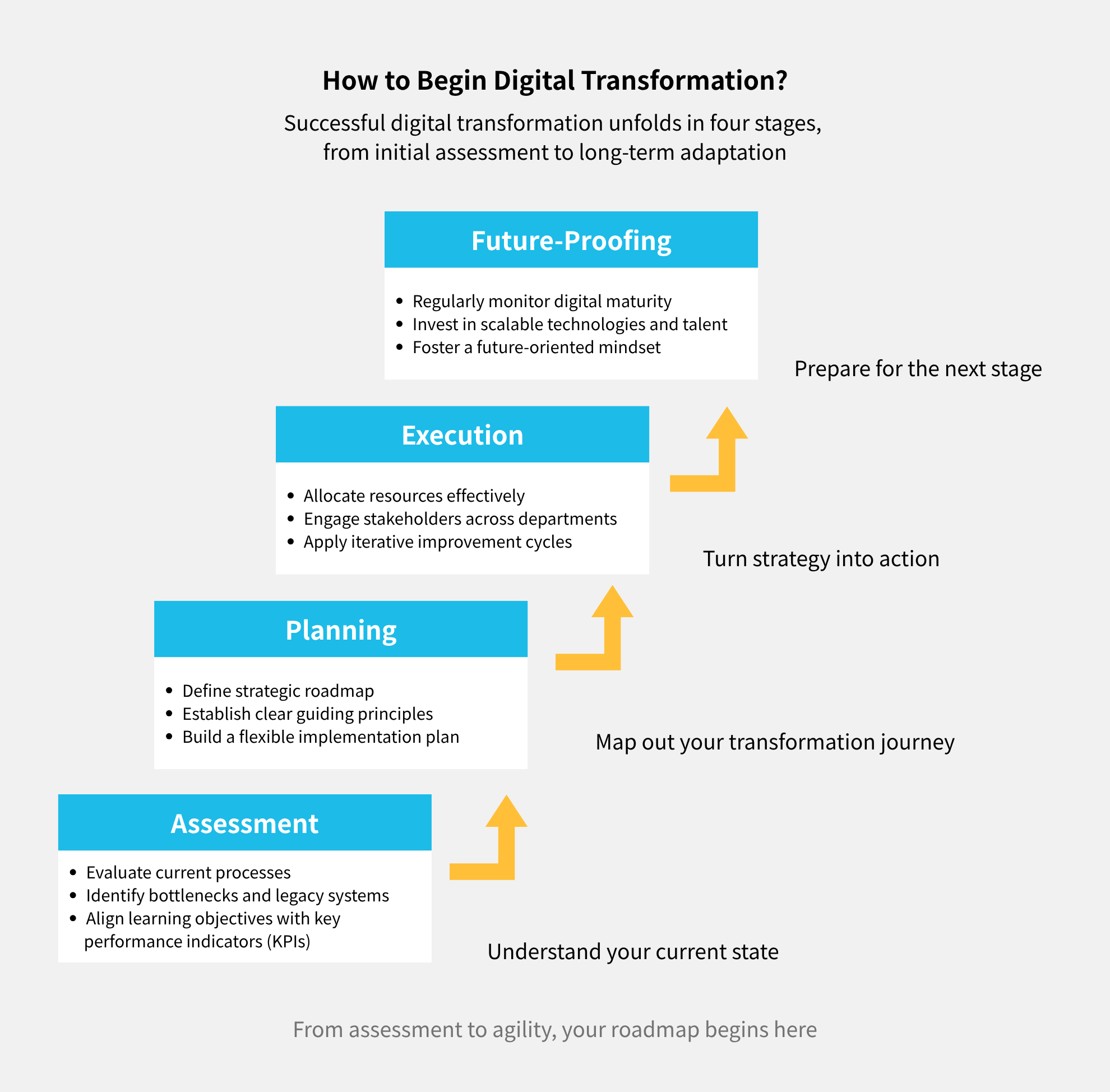

Based on our past experience, this article explains what digital transformation truly is, why it matters to your business, and provides a clear roadmap to guide you through the four key stages — Assess, Plan, Execute, and Future-proof — helping you take the first confident step toward transformation.

However, theory alone is not enough. This article also highlights the importance of tools and technologies in digital transformation, helping you define the critical factors within your production process — including digital culture, cross-department collaboration, and workforce training — so that your organization can move forward toward its next goal: achieving sustainable industrial growth and development.

Catalog

- 1. Who Needs Digital Transformation

- 2. Digital Transformation in Manufacturing

- 3. Digital Transformation for Sustainability-Driven Organizations

- 4. When to Start Digital Transformation

- 5. How to Initiate Digital Transformation

- 6. Tools That Drive Transformation

- 7. Technologies That Drive Transformation

- 8. Process and Tool Evolution

1. Who Needs Digital Transformation

Digital transformation is not exclusive to large tech enterprises or multinational corporations.

In today’s fast-changing market, organizations of all sizes, industries, and maturity levels must evaluate their degree of digitalization to stay competitive.

The purpose of this evaluation lies in the fact that every company is at a different stage of development. Digital transformation is not a one-size-fits-all approach.

Some organizations face increasing operational complexity; others are under pressure to innovate, reduce costs, or enhance customer experience.

Certain businesses are responding to external disruptions, while others are proactively seeking competitive advantages or pursuing sustainability goals.

To determine whether your company needs digital transformation, you must first understand your current pain points, future objectives, and adaptability.

For some, transformation begins with automating core processes; for others, it may involve a fundamental rethink of the business model, supply chain, or customer engagement strategy.

In short, digital transformation is not a standardized solution—it is a strategic decision rooted in business value, resilience, and long-term growth.

2. Digital Transformation in Manufacturing

Driven by automation, artificial intelligence (AI), and the Internet of Things (IoT), the manufacturing industry is undergoing a profound transformation.

Enterprises that once relied on manual operations are now evolving into smart factory ecosystems, leveraging real-time data, predictive analytics, and interconnected systems to achieve faster and more efficient production.

To stay competitive, manufacturers are increasingly adopting systems such as Manufacturing Execution Systems (MES) and Advanced Planning and Scheduling (APS) to gain tighter control of production lines, optimize resource utilization, and respond more flexibly to market demand.

Without digital transformation, companies risk falling behind in productivity, quality, and supply-chain resilience.

- Client Case – Electronics Manufacturer

In 2019, we implemented DigiHua’s MES system for an electronics manufacturer in China. Through real-time production monitoring, the company reduced unplanned downtime by over 30% and improved on-time delivery rates across multiple production lines.

- Client Case – Precision Parts Manufacturer

This precision components company adopted DigiHua’s APS solution. By integrating IoT sensors to monitor material availability and equipment status, the system dynamically adjusted daily production schedules, significantly enhancing flexibility in handling urgent orders.

3. Digital Transformation for Sustainability-Driven Organizations

In recent years, the impact of pandemics, wars, climate change, and rising sea levels has prompted banks, financial institutions, investors, and global brands to place greater emphasis on ESG performance—that is, Environmental, Social, and Governance criteria.

International organizations have also established relevant standards, such as ISO 14064 for organizational carbon footprints, ISO 14067 for product carbon footprints, and ISO 50001 for energy management—making ESG a critical factor influencing corporate performance.

To achieve sustainability goals, many organizations are turning to digital transformation (DX).

By digitalizing paper-based processes, optimizing resource utilization, and using data to track emissions and resource consumption, companies can minimize their environmental impact and move more effectively toward sustainability objectives.

Digitalization tools not only help eliminate waste and reduce operational costs, but also enhance transparency and accountability—attributes increasingly demanded by regulators and consumers alike.

In this context, digital transformation is not merely a path to greater efficiency; it has become the foundation for long-term business resilience and responsible growth.

4. When Is the Right Time for Digital Transformation?

Common signs include increasing industry pressure, outdated and slow internal processes, misalignment between operations and key performance indicators (KPIs), and a widening skills gap among employees.

These indicators suggest deeper, often hidden challenges—such as a lack of digital maturity and adaptability—causing the organization to fall behind in efficiency, innovation, and long-term growth.

Whether you’re facing operational bottlenecks or struggling to retain tech-savvy talent, digital transformation (DX) offers both immediate and strategic solutions to help your business stay resilient and competitive.

5. How to Start Your Digital Transformation

Taking a structured, phased approach helps reduce the complexity of digital transformation and ensures everyone moves toward a shared goal. Below are the four key stages that guide a successful transformation journey—from initial assessment to long-term adaptability.

- Assess: Understanding the Current State

Begin by evaluating workflows to establish a clear baseline for transformation. Identify inefficiencies, redundancies, or legacy systems that hinder performance. Then, set goals directly tied to business outcomes—whether that means improving customer experience, accelerating production, or entering new markets.

At this stage, DigiHua conducts a comprehensive operational review using industry benchmarks and transformation frameworks to analyze existing challenges and long-term opportunities. Our team aligns your current processes with best practices and identifies your digitalization maturity, providing a clear, actionable starting point for your digital transformation roadmap.

- Plan: Strategy and Roadmap Development

An effective strategy and roadmap address organizational pain points, prevent misaligned investments, and avoid resource waste or project delays that erode confidence in the transformation process. Acting as a compass for the entire journey, strategic planning involves defining guiding principles, core values, and priorities.

Equally important is roadmap flexibility. In a rapidly changing business environment, transformation projects must remain agile to pivot as needed without losing momentum.

At this stage, DigiHua uses the Manufacturing Operations Management (MOM) framework as a foundation, covering over eight solution modules to resolve diverse operational challenges. This modular structure allows us to customize each organization’s transformation journey, ensuring investments are targeted, scalable, and sustainable.

- Execute: Organizational Alignment

Turning plans into action requires careful resource allocation—assigning the right people, tools, and budgets to maintain sustainable progress. Engaging all stakeholders is crucial. Strong stakeholder participation and proactive change management help align departments, minimize resistance, and foster a culture of collaboration.

Transformation should never be confined to IT or management teams—it must be owned by the entire organization.

At this stage, DigiHua convenes a Project Management Office (PMO) with stakeholders to customize the transformation process or replicate proven success cases. Based on past experience, most clients adopt an iterative improvement model, enabling incremental progress, learning from each phase, and continuous optimization. This approach builds confidence and ensures early wins as the transformation scales.

- Future-Proof: Building Long-Term Agility

True transformation is not only about solving today’s problems—it’s about ensuring long-term agility and readiness for future change. Focusing on digital maturity helps assess current capabilities while identifying areas for further development.

At this stage, DigiHua helps future-proof your investments by recommending scalable technologies, cross-functional training, and adaptive platforms—ensuring your organization can continuously evolve with emerging trends and customer expectations.

6. Tools That Drive Digital Transformation

Many successful digital transformation (DX) initiatives are built upon the deployment of integrated enterprise systems.

These core systems form the digital backbone that supports efficient operations, real-time decision-making, and scalable growth.

- Manufacturing Execution System (MES)

MES plays a crucial role in bridging the gap between the shop floor and enterprise level operations.

It provides real-time visibility into production processes, enabling manufacturers to monitor performance, enforce quality standards, and respond swiftly to disruptions.

- Advanced Planning and Scheduling (APS)

APS optimizes production plans, balances workloads, and aligns capacity with demand.

By doing so, companies can significantly improve efficiency, shorten lead times, and increase on-time delivery rates—key indicators of operational excellence.

- System Integration: The Key to Agility

Equally important is the ability to integrate MES, APS, ERP, and other digitalization tools into a unified environment.

Seamless integration ensures data consistency across departments, eliminates information silos, and builds the foundation for agility, real-time analytics, and cross-functional collaboration.

7. Technologies That Drive Transformation

Smart manufacturing systems form the foundation of digital transformation (DX), while advanced technologies enhance organizational capability. These tools open new pathways for greater visibility, responsiveness, and decision-making power across the enterprise.

- Internet of Things (IoT)

Connects physical assets such as machines, tools, and infrastructure to digital systems, enabling real-time monitoring, predictive maintenance, and smarter resource allocation.

- Data Analytics

Identifies inefficiencies and abnormalities in operations using existing data. This allows organizations to make faster, data-driven decisions—whether optimizing inventory, improving production flow, or understanding customer behavior. Data analytics strengthens both strategic planning and daily operational efficiency.

- AI-Driven Intelligence

Although artificial intelligence (AI) remains emerging in many industries, it offers exciting potential—such as automating complex decisions, extracting insights from unstructured data, and enabling new modes of user interaction.

- Cybersecurity and Risk Management

As digital ecosystems expand, potential risks grow alongside them. Therefore, cybersecurity must be a fundamental part of every transformation strategy.

Protecting sensitive data, securing connected devices, and training teams in digital hygiene are essential to maintaining trust and ensuring long-term resilience.

Together, these technologies and industrial systems form the core of future-ready organizations—empowering teams to act faster, plan smarter, and scale confidently.

8. Process and Tool Evolution

For manufacturers preparing for digital transformation (DX), improving everyday workflows is often the most practical starting point. Tools that support mobile technology, digitalized (Digitalization) workflows, and lightweight app development can deliver quick wins—especially in areas such as internal communication, approvals, and task tracking.

- Mobile-Friendly Solutions

Mobile-enabled systems allow employees to access business platforms and collaborate anytime, anywhere, improving agility and operational resilience.

Even lightweight, department-specific applications can simplify processes and eliminate redundant tasks without requiring a complete system overhaul.

- DigiHua’s MES Mobile Solution

We recommend leveraging DigiHua’s MES mobile solution, which extends shop-floor visibility and control directly to handheld devices.

Supervisors and operators can monitor production status, approve workflows, and record quality checks in real time—reducing response time, minimizing manual follow-ups, and capturing critical data directly at the source.