Introduction|

DIGIHUA has supported many countries and industries in the early stages of manufacturing development, where discussions about AI often move too quickly. What they need more is to turn data into actionable information to catch up with today’s rapidly evolving business landscape, which makes digital transformation a necessity.

However, many organizations remain unclear about where to begin, how to move forward, and whether they’re even ready. For some, digitization has brought convenience and cost savings. For others, it’s sparked a deeper realization: that surviving and thriving in a dynamic market requires more than just going paperless.

This article explores the full scope of digital transformation, from foundational concepts like digitization and digitalization, to the strategies, tools, and cultural shifts required for meaningful change. We’ll walk through common starting points, industry use cases, and the risks and rewards of making the leap, with one central goal: helping your organization assess where it stands and decide what comes next.

Summary

We will guide you step by step to understand the difference between digitization, digitalization, and digital transformation. Drawing on over 30 years of experience, we reveal how four key objectives:cost reduction, efficiency, quality improvement, and inventory reduction, directly shape the future of manufacturing during the transformation journey.

Follow the roadmap in this article to step through assess, plan, execute, and future-proof. Leverage tools such as MES, APS, IoT, data analytics, and digital workflows to identify critical factors in your production process, including digital culture, cross-functional collaboration, and employee empowerment, and take the next step toward achieving your industry and growth goals.

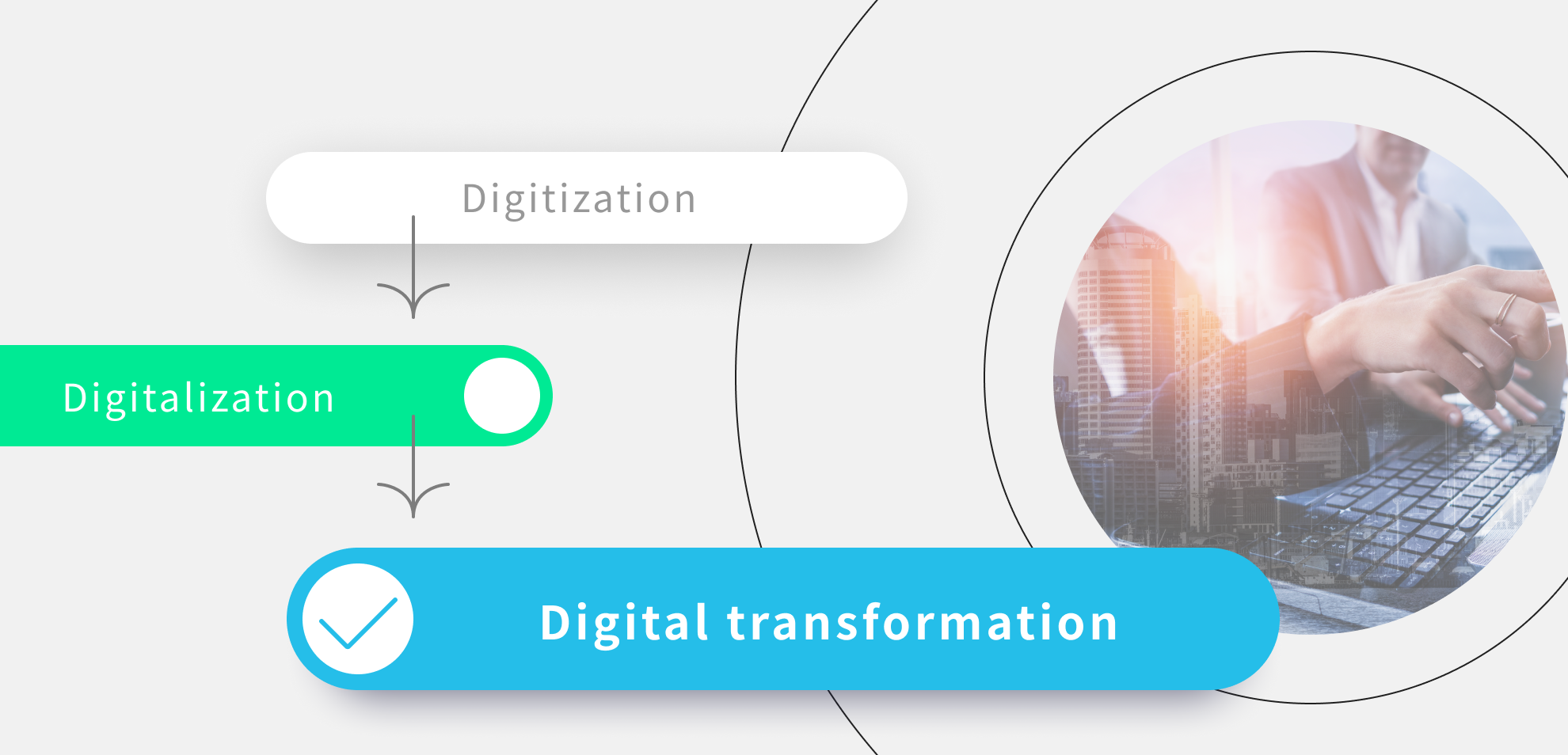

1. What Is Digital Transformation? Understanding the Key Definitions

Before diving into strategies or tools, it’s essential to understand the foundational concepts behind digital transformation. While digitization, digitalization, and digital transformation are often used interchangeably, they refer to distinct stages in a company’s digital journey.

- Digitization is the process of converting physical or analog information. Such as paper documents or printed records into digital formats that can be processed by systems. Common examples include using OCR (Optical Character Recognition) or scanning tools to transform paper-based data into searchable digital files.

- Digitalization goes a step further. It involves using digital technologies to improve workflows, streamline communication, and enhance information accessibility. This could include implementing cloud-based document management systems or automating internal approvals to boost efficiency and agility across departments.

- Digital transformation, by contrast, represents a broader and more strategic shift. It refers to the integration of digital technologies across all areas of an organization, fundamentally changing how a business operates and delivers business value. It is not just about adopting new tools, it requires a cultural shift, a digital-first mindset, and a long-term vision for innovation, resilience, and competitive advantage.

Understanding the differences between these terms helps organizations assess where they currently stand, and where they need to go next.

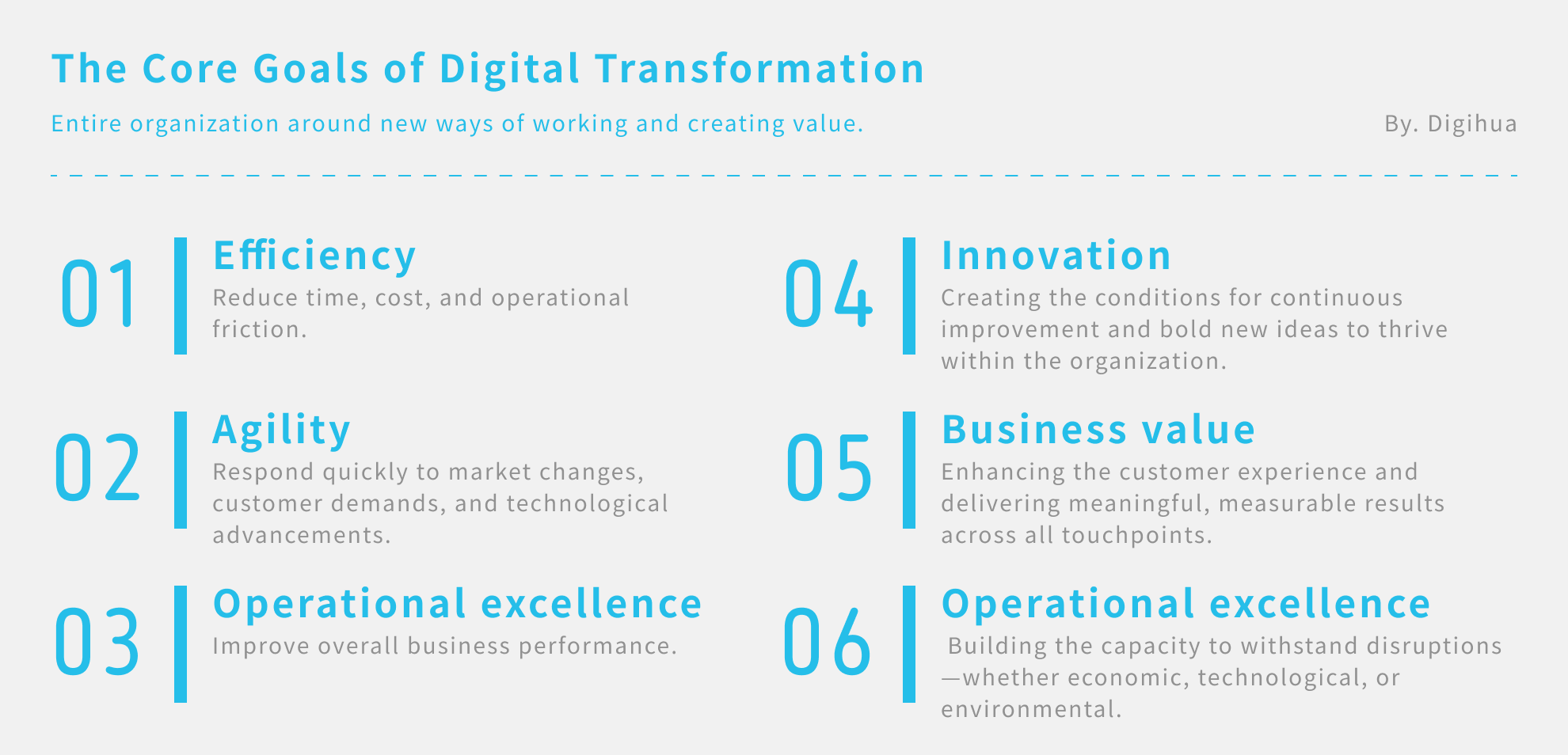

1-1. The Core Goals of Digital Transformation

At its heart, digital transformation is about more than just upgrading technology and it’s also about aligning the entire organization around new ways of working and creating value. Successful transformation efforts are typically driven by several key goals:

- Efficiency: Automating repetitive tasks and optimizing workflows to reduce time, cost, and operational friction.

- Agility: Enabling organizations to respond quickly to market changes, customer demands, and technological advancements.

- Operational excellence: Streamlining internal processes and systems to improve overall business performance.

- Innovation: Creating the conditions for continuous improvement and bold new ideas to thrive within the organization.

- Business value: Enhancing the customer experience and delivering meaningful, measurable results across all touchpoints.

- Business resilience: Building the capacity to withstand disruptions—whether economic, technological, or environmental—while maintaining momentum and continuity.

These goals form the foundation of any meaningful transformation strategy, helping organizations future-proof their operations and remain competitive in dynamic markets.

1-2. The Cultural Impact of Digital Transformation

Achieving the goals of digital transformation also requires significant changes to the way people think, collaborate, and lead. At its core, digital transformation is a cultural shift, not merely a technological upgrade. It challenges long-held assumptions and compels organizations to reevaluate how they define success, how they work together, and how they engage with customers.

Transitioning from a traditional organizational structure to one that supports a digital-first mindset means breaking down silos, encouraging cross-functional collaboration, and fostering a culture of agility and adaptability. Employees are empowered to take ownership of innovation and are encouraged to seek out smarter, faster ways of working.

This shift is not always easy. It requires investment in employee upskilling, leadership commitment, and an environment that supports experimentation without fear of failure. Successful transformation stories often include a strong emphasis on internal communication, transparency, and alignment between leadership and teams.

The result of such a transformation is not just improved business performance,also a workforce that’s more engaged, flexible, and future-ready. By embedding digital thinking into the organizational culture, companies can better respond to change, attract top talent, and continuously evolve in line with emerging opportunities.

Ultimately, digital transformation is as much about people as it is about platforms. Companies that recognize this human dimension and actively nurture it, are the ones that truly unlock the full potential of their transformation journey.

2. Who Needs Digital Transformation? Which Organizations Are Ready to Adopt?

Digital transformation is no longer a buzzword reserved for large tech firms or multinational corporations. In today’s fast-changing market landscape, every organization—regardless of size, industry, or maturity must evaluate its digital readiness.

But this doesn’t mean that every company is at the same stage, or that transformation should look the same for everyone.

Some businesses face growing operational complexity, while others are under pressure to innovate, cut costs, or improve customer experience. Some are responding to external disruptions, while others are proactively seeking competitive advantage or pursuing sustainability goals.

Understanding who needs digital transformation begins with a deeper look at the organization’s current pain points, future ambitions, and ability to adapt. For some, transformation may start with automating core processes. For others, it may involve a full rethinking of business models, supply chains, or customer engagement strategies.

In short, digital transformation is not a one-size-fits-all solution, it’s a strategic decision rooted in business value, resilience, and long-term growth.

2-1. Manufacturing: Adapting to Automation and Smart Factories

The manufacturing sector is undergoing a profound transformation driven by the rise of automation, AI, and the Internet of Things (IoT). Companies that once relied on manual processes are now expected to operate as part of a smart factory ecosystem, where real-time data, predictive analytics, and system connectivity enable faster, more efficient production.

To stay competitive, manufacturers must implement systems like Manufacturing Execution Systems (MES) and Advanced Planning and Scheduling (APS) tools that allow for tighter control of production lines, resource optimization, and agility in responding to market demand. Without embracing digital transformation, these companies risk falling behind in terms of productivity, quality, and supply chain resilience.

In a 2019 case, we implemented an DIGIHUA sMES system to monitor production in real time for a mat product manufacturer in China, and they reduced unplanned downtime by over 30%, and improved on-time delivery rates across multiple product lines.

Another example, also from China, involves a precision parts supplier, it adopted DIGIHUA APS software integrated with IoT sensors to adjust daily production schedules based on live material availability and equipment status. This significantly increased their flexibility in handling rush orders.

2-2. Small Businesses: Scaling Strategically With Limited Resources

For small and medium-sized enterprises (SMEs), the idea of digital transformation can seem overwhelming, but it doesn’t have to be. In fact, smaller companies often have the advantage of being more agile and less constrained by legacy infrastructure.

By adopting a crawl-walk-run approach, SMEs can start small, perhaps with cloud-based tools, digital workflows, or basic analytics, and gradually scale up their digital capabilities over time. Even incremental changes can deliver significant improvements in efficiency, cost savings, and customer engagement.

Digital transformation empowers small businesses to compete with larger players by unlocking access to better data, smarter decision-making, and leaner operations.

2-3. Sustainability-Driven Organizations: Aligning Digital With Green Goals

In recent years, the impacts of the pandemic, wars, global climate change, and rising sea levels have made banks and financial institutions, investors, and international brands place greater emphasis on corporate performance across the three dimensions of ESG. International organizations have also established relevant standards, such as ISO 14064 for organizational carbon footprint, ISO 14067 for product carbon footprint, and ISO 50001 for energy management. ESG has become a critical factor influencing a company’s operational performance.

Many organizations have been forced to shift toward digital transformation to achieve their sustainability goals. By digitizing paper-based processes, optimizing energy use, and leveraging data to track emissions and resource consumption, companies can reduce their environmental impact and move toward sustainability targets more effectively.

Digital tools not only help eliminate waste and lower operational costs, they also support greater transparency and accountability, which are increasingly expected by regulators and consumers alike. In this context, digital transformation is not just a path to efficiency, it’s a cornerstone of long-term business resilience and responsible growth.

2-4. Signs It’s Time to Embrace Digital Transformation

Recognizing when to begin your digital transformation journey is just as important as knowing how. Common indicators include increasing industry pressure, outdated internal processes, misalignment between current operations and KPI targets (goal alignment issues), or a growing skills gap among employees.

In many cases, these signals point to a deeper challenge: a lack of digital maturity within the organization. Without the ability to adapt and evolve, companies risk falling behind in efficiency, innovation, and long-term growth.

Whether you’re facing operational bottlenecks or struggling to retain a tech-savvy workforce, digital transformation can offer both immediate and strategic solutions.

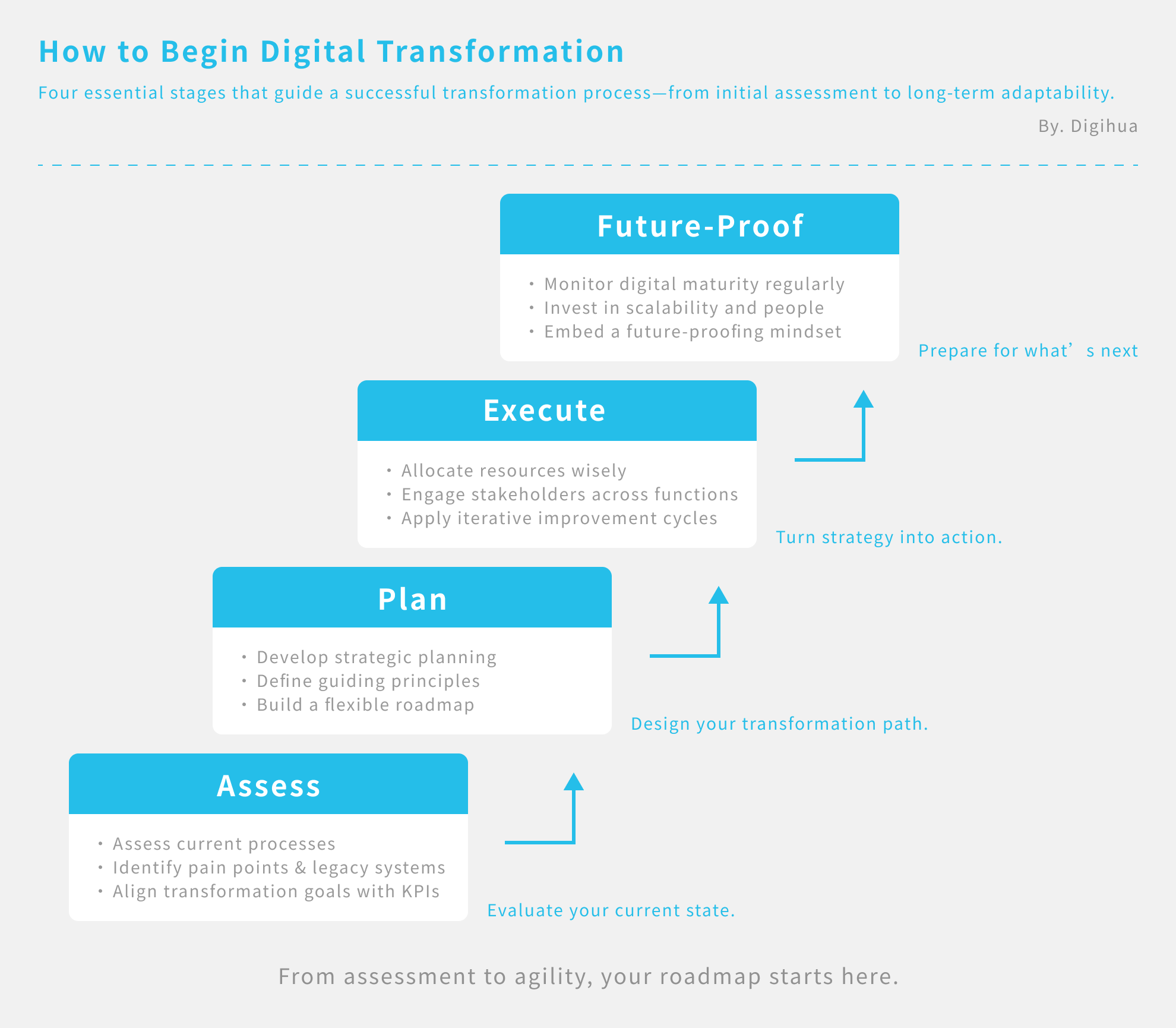

3. How to Begin Digital Transformation: Strategy and Process Recommendations

Starting a digital transformation journey can feel overwhelming, but a structured, phased approach helps reduce complexity and align everyone around a common goal. Below are four essential stages that guide a successful transformation process—from initial assessment to long-term adaptability.

3-1. Initial Assessment: Understanding Where You Stand

The first step is to assess current processes and workflows to identify inefficiencies, redundancies, or legacy systems that hinder growth. This diagnostic phase provides a clear baseline for your transformation journey.

Equally important is establishing goal alignment—ensuring that your digital objectives are directly tied to business outcomes, whether it’s improving customer experience, accelerating production, or entering new markets.

At this stage, DIGIHUA will conduct a thorough operational review, leveraging industry benchmarks and transformation frameworks to uncover both immediate issues and long-term opportunities. Our team helps map current processes against best practices, identify gaps in digital maturity. This ensures that your assessment phase doesn’t just describe where you are, it defines a clear, actionable starting point for the next steps in your digital transformation roadmap.

3-2. Strategic Planning and Roadmap Design

Many organizations enter the transformation process with vague or undefined goals. This lack of clarity often leads to misaligned investments, wasted resources, and frustration when outcomes fail to meet expectations. As a result, the proposed products may look impressive on paper but fail to address the organization’s true pain points, ultimately delaying progress and eroding confidence in the transformation process.

Once the gaps and goals are identified, organizations can engage in strategic planning, defining a transformation strategy tailored to their size, structure, and industry.

This planning process should include the creation of guiding principles, core values and priorities that will serve as a compass throughout the journey. Additionally, having roadmap flexibility is key. Business environments are dynamic, and transformation projects must remain agile to adjust course when needed without losing momentum.

At DIGIHUA Intelligent Systems, we believe that effective transformation starts with clarity. Only after confirming the root problems and setting clear priorities do we recommend solutions, ensuring that every product we introduce is directly aligned with the client’s real needs.

Our approach is built on a comprehensive Manufacturing Operations Management (MOM) framework, encompassing more than eight specialized solutions designed to address a wide range of operational pain points. This modular structure allows us to tailor the transformation journey to each organization’s unique context, ensuring that investments are targeted, scalable, and sustainable.

3-3. Execution and Organizational Alignment

Turning plans into action requires thoughtful resource planning, allocating the right people, tools, and budgets to ensure progress is sustainable.

Engaging all stakeholders is critical. Strong stakeholder engagement and proactive change management can help align departments, reduce resistance, and foster a culture of collaboration. Transformation should not be confined to IT or management, it must be owned across the organization.

That’s why DIGIHUA convenes an initial transformation meeting with all relevant stakeholders, facilitated by our senior consultants. This session covers a wide scope: confirming transformation objectives, validating the identified pain points, reviewing current system architecture, assessing system compatibility, and discussing the integration approach within the client’s operational framework. We also establish communication protocols, milestone checkpoints, and risk management measures to ensure alignment before execution begins.

For different clients, we tailor transformation processes to meet the specific needs of their industries, or replicate proven success stories directly. Based on past experience, many choose the iterative improvement model. Using an iterative improvement model ensures you can make incremental changes, learn from each phase, and continue optimizing over time. This allows teams to generate early wins and build confidence as the transformation scales.

3-4. Preparing for the Future

True transformation isn’t just about solving today’s problems, it’s about ensuring long-term agility and readiness. Focusing on your organization’s digital maturity helps benchmark current capabilities while identifying areas that need further development.

Investing in future-proofing, such as scalable technologies, cross-functional training, and adaptable platforms. Ensures your business can keep evolving in line with emerging trends and customer expectations.

4. What Tools and Technologies Drive Transformation?

4-1. Enterprise Systems: The Foundation of Operational Agility

At the heart of many successful digital transformation initiatives lies the deployment of integrated enterprise systems. These core platforms serve as the digital backbone that supports efficient operations, real-time decision-making, and scalable growth.

For manufacturing and production-intensive industries, Manufacturing Execution Systems (MES) play a critical role in bridging the gap between the shop floor and the enterprise level. MES solutions offer real-time visibility into production processes, helping businesses monitor performance, enforce quality standards, and respond quickly to disruptions.

Complementing MES is Advanced Planning and Scheduling (APS) software, which enables manufacturers to optimize production plans, balance workloads, and align capacity with demand. By using APS, companies can significantly improve efficiency, reduce lead times, and enhance on-time delivery. Key metrics for achieving operational excellence.

Equally important is system integration, the ability to connect MES, APS, ERP, and other digital tools into a unified environment. Seamless integration ensures data consistency across departments and eliminates silos, laying the groundwork for agility, real-time analytics, and cross-functional collaboration.

These enterprise systems form the structural core of a future-ready organization together, enabling teams to act faster, plan smarter, and scale with confidence.

4-2. Advanced Technologies: Building Blocks for Smarter Operations

While core enterprise systems lay the foundation for digital transformation, advanced technologies help organizations take their capabilities to the next level. These tools unlock new ways to improve visibility, responsiveness, and decision-making across the business.

The Internet of Things (IoT) connects physical assets, like machines, tools, and infrastructure, to digital systems, enabling real-time monitoring, predictive maintenance, and smarter resource allocation. For manufacturers, logistics providers, and even service-based industries, IoT serves as a bridge between data and action.

Data analytics is another essential pillar. By harnessing the data already flowing through your systems, organizations can identify patterns, uncover inefficiencies, and make informed decisions faster. Whether optimizing inventory levels or analyzing customer behavior, analytics supports both strategic planning and day-to-day operational efficiency.

As digital ecosystems grow, so do potential risks. That’s why cybersecurity must be a foundational component of any transformation strategy. Protecting sensitive data, securing connected devices, and educating teams on digital hygiene are essential for maintaining trust and long-term resilience.

Although still emerging in many sectors, artificial intelligence (AI) and Generative AI offer exciting possibilities—such as automating complex decisions, generating insights from unstructured data, or enabling new types of user interactions. While not every organization is ready to adopt AI today, preparing your digital infrastructure now will make it easier to embrace these tools when the time is right.

4-3. Enabling Digitization Through Workflow and Tools

For organizations just beginning their digital transformation journey, improving day-to-day workflows is often the most practical starting point. Tools that support mobile technology, digital workflows, and simple application development can deliver quick wins, especially in areas like internal communication, approvals, and task tracking.

Mobile-friendly solutions allow employees to access business systems and collaborate from anywhere, improving agility and operational flexibility. Even lightweight apps, customized for specific departments or use cases, can streamline processes and eliminate redundant tasks without requiring a full system overhaul.

A good example is our eMES mobile solution, which extends shop-floor visibility and control directly to handheld devices. By allowing supervisors and operators to review production status, approve workflows, and record quality checks on the go, eMES helps reduce response time, cut down on manual follow-ups, and ensure that critical data is captured instantly at the source. This not only boosts efficiency but also enhances quality control and accelerates overall speed to market.

These mobile-enabled, real-time workflows represent a significant leap forward in the digitalization process, transforming static, paper-based operations into fully connected, responsive, and data-driven systems.

5. The Ultimate Success Factor In Digital Transformation

While tools and systems are essential enablers of digital transformation, they are not the end goal. Ultimately, transformation succeeds or fails based on people. Culture, leadership, and team capability are what turn digital initiatives into lasting change.

Creating a strong digital culture is the first step. This means fostering an environment where experimentation is encouraged, failure is treated as part of learning, and new ideas are welcomed. Organizations that reward innovation and openness are better equipped to adapt to change and stay competitive.

Cross-functional collaboration is equally critical. Traditional silos can slow down transformation efforts and block information flow. By encouraging teams across departments (IT, operations, sales, HR) to work together, companies unlock deeper insights and deliver more cohesive outcomes.

As technology evolves, so must people. Investing in employee upskilling is essential to ensure that your workforce can work confidently with new systems, data, and processes. This also helps reduce resistance to change by giving employees the knowledge and confidence to embrace digital tools.

Certainly, this cultural shift requires strong leadership support. Leaders must model digital behaviors, communicate a clear vision, and empower teams to take ownership of their role in the transformation. True progress happens when employees feel trusted, supported, and empowered to contribute meaningfully.

Most importantly, transformation should be human-centered. While automation can remove repetitive tasks, it is people who drive creativity, build relationships, and shape customer experiences. Keeping people at the center ensures that technology serves the business, not the other way around.

6. The Benefits and Risks of Transformation

After exploring the tools, strategies, and cultural foundations of digital transformation, it’s worth taking a moment to reflect: Where is your organization on this journey? Have you already digitized your core operations, or are you still navigating paper-based workflows? Do your teams have access to the right systems and support, or are outdated tools and siloed processes holding you back?

Understanding your current level of digital maturity helps clarify what’s working, what’s missing, and where the greatest opportunities lie. Sometimes the path forward is about upgrading existing platforms or improving system compatibility. Other times, it means building entirely new capabilities from the ground up.

What’s certain is that transformation is no longer optional. Organizations that delay risk falling behind, not just in technology, but in talent retention, customer engagement, and market responsiveness.

But before making bold moves, it’s important to understand both sides of the equation. Digital transformation comes with meaningful benefits but also real risks.

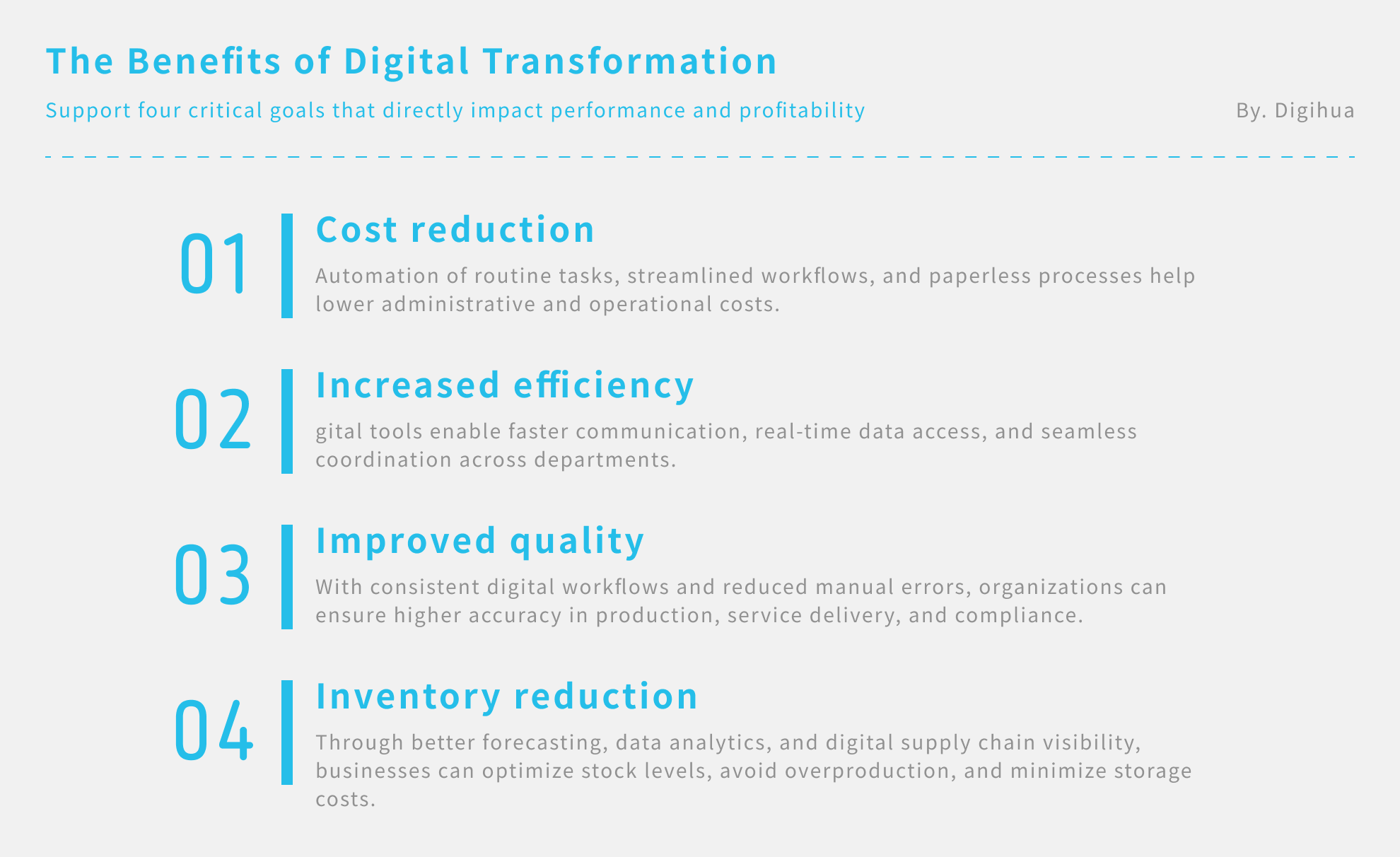

6-1. The Benefits of Digital Transformation

For businesses seeking tangible outcomes, digital transformation isn’t just a strategic buzzword, it’s also a proven path to operational excellence. When implemented effectively, transformation can support four critical goals that directly impact performance and profitability:

- Cost reduction: Automation of routine tasks, streamlined workflows, and paperless processes help lower administrative and operational costs. By eliminating inefficiencies, businesses can redirect resources to higher-value activities.

- Increased efficiency: Digital tools enable faster communication, real-time data access, and seamless coordination across departments. This shortens cycle times, accelerates decision-making, and boosts overall productivity.

- Improved quality: With consistent digital workflows and reduced manual errors, organizations can ensure higher accuracy in production, service delivery, and compliance. This leads to fewer defects, stronger customer satisfaction, and a more reliable output.

- Inventory reduction: Through better forecasting, data analytics, and digital supply chain visibility, businesses can optimize stock levels, avoid overproduction, and minimize storage costs. This creates a leaner, more responsive operation.

These outcomes are not theoretical, they reflect what’s achievable when digital transformation is aligned with real business needs. Whether you’re aiming to scale sustainably or simply operate smarter, the right digital foundation can deliver measurable results where it counts most.

6-2. The Risks of Digital Transformation: Challenges to Anticipate and Manage

While the benefits of digital transformation are substantial, the journey is not without its challenges. Understanding the risks involved allows organizations to plan ahead and mitigate potential disruptions.

- Cybersecurity risk: As companies become more connected and data-driven, they also become more vulnerable to cyber threats. Without proper security protocols, even small vulnerabilities can lead to data breaches, operational downtime, or reputational damage. The way of DIGIHYA to mitigate these risks is to make strategic choices between cloud-based and on-premises deployments—or a hybrid approach—based on your industry, regulatory environment, and operational needs.

- System compatibility: Trying to integrate outdated infrastructure with modern tools can result in data inconsistencies, performance issues, or costly workarounds. Without a clear system integration plan, businesses risk building unstable or fragmented digital ecosystems. DIGIHUA system ensures smooth delivery and interoperability with other vendors’ systems. A well-coordinated integration process not only reduces the risk of technical conflicts but also maximizes the value of existing investments.

- Cultural resistance: Transformation often meets internal resistance—from employees unsure of their role in the new system to managers hesitant to change familiar processes. Without strong change management and leadership support, digital initiatives can stall before delivering results.

- Misaligned investments: Rushing into high-cost technology implementations without a clear strategy can lead to low ROI. A lack of goal alignment or resource planning can cause overspending on tools that don’t solve the real problems. So, our team helps align goals with business priorities, validate requirements, and select solutions that directly address the real operational challenges.

The good news? These risks are manageable, with the right partners, phased execution, and a strong internal culture. At DIGIHUA , our 30 years of manufacturing and digital transformation experience means we know how to identify potential pitfalls early and design strategies to mitigate them. We adopt a phased, measurable approach, starting with clear goal alignment, integrating the right systems, and ensuring smooth stakeholder collaboration. This method not only keeps risks under control but also maximizes returns, delivering tangible benefits such as lower costs, higher efficiency, better quality, and leaner inventory. Transformation is not about moving fast at all costs; it’s about moving forward with clarity, coordination, and confidence.

Conclusion: Transformation Is a Journey—You Don’t Have to Take It Alone

Digital transformation is not a one-size-fits-all solution, nor is it a destination you reach overnight. It’s a journey that requires clear direction, the right tools, a supportive culture, and above all, experienced guidance.

For organizations still exploring their path forward, the smartest move isn’t to rush into new technology—it’s to work with a partner who understands your industry, your operations, and your goals.

At DIGIHUA, we combine deep experience in manufacturing, proven technical know-how, and a strong consulting mindset to help businesses move from complexity to clarity. Whether you’re taking your first step or optimizing an existing digital strategy, our team delivers practical solutions that align with your needs, not generic templates.

?A-Comprehensive-Guide-1024x576.webp)