About Digihua

Digihua System

Digihua

system

Innovative and professional intelligent manufacturing navigator

Digihua Intelligent has more than 20 years of experience in production scheduling and manufacturing execution systems. With a focus on smart manufacturing and industrial internet applications, we have deep roots in Taiwan, a strong presence in mainland China, and reach throughout the Asia Pacific region. We have received support and recognition from over 1800 discrete implementation enterprises and more than 180 semiconductor customers, achieving more than 36 intelligent demonstration bases throughout the Asia Pacific.

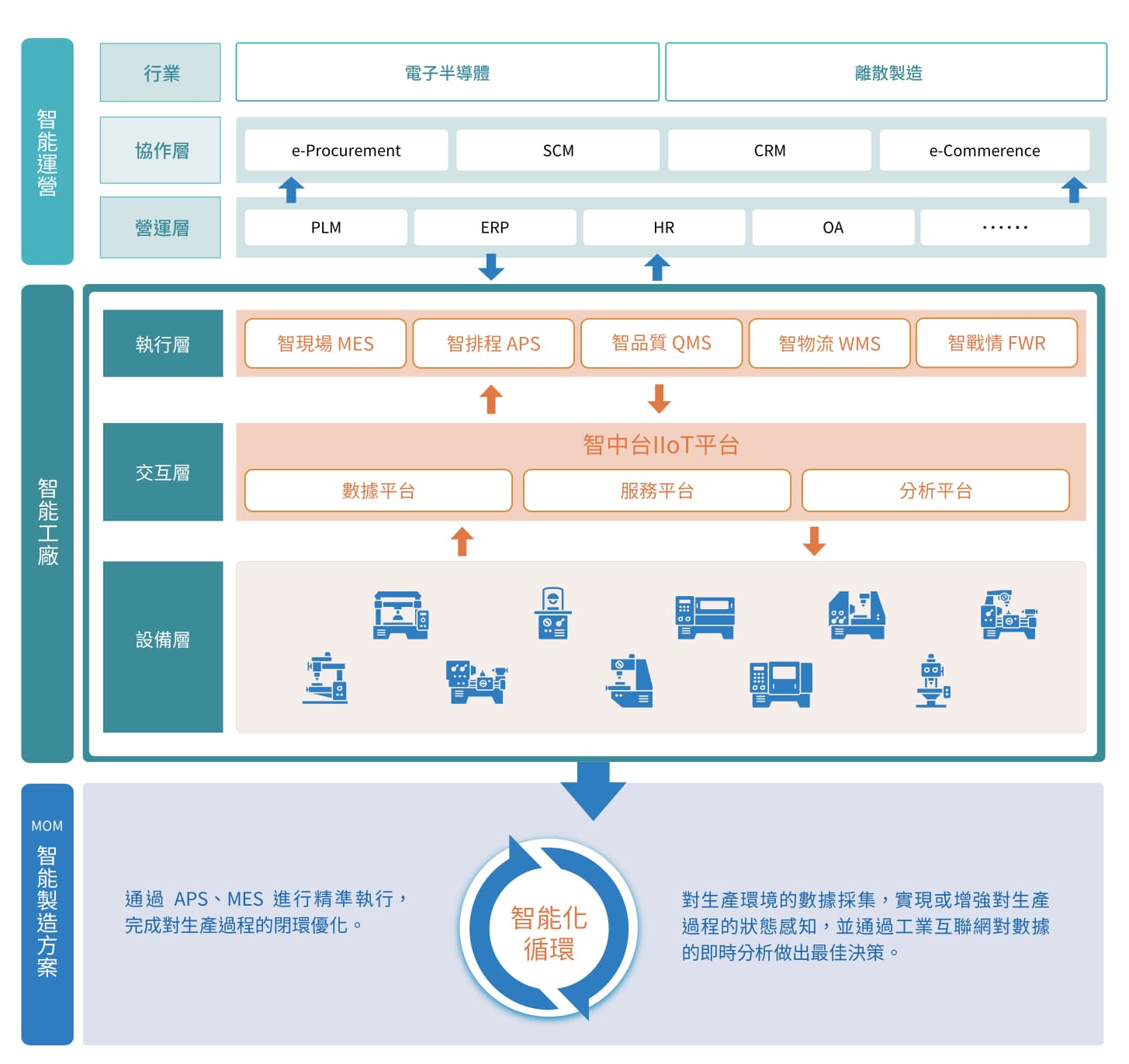

Using intelligent manufacturing operations management (MOM) as a blueprint, we have developed manufacturing execution management systems (MES), advanced scheduling systems (APS), quality management systems (QMS), intelligent war rooms, and intelligent middleware (IIoT) products. We also provide industrial internet application and IT+OT integration solutions to help manufacturing industries transform into digital, networked, and intelligent operations, to meet the challenges of market demand, production environment, and supply chain.

Digihua is committed to creating digital value for our customers,

using leading industry solutions to help them achieve “cost reduction” , “efficiency improvement” , “quality enhancement” , “inventory reduction” , competitive advantages.

Development history

With over 28 years of experience and capabilities in intelligent manufacturing

With over 20 years of experience and capabilities in intelligent manufacturing, Digihua Intelligent was formed by the merger of two long-established and high-tech companies. One was iMES Technology, established in 1995 as a spin-off from Taiwan’s Industrial Technology Research Institute, which has long focused on semiconductor MES solutions. The other was DigiChain Information, established in 2000 ads an investment by Digiwin Software, which specializes in advanced scheduling system (APS) research and implementation, with many successful cases in large electronic assembly and PCB factories.

The merger of the two companies was aimed at providing customers with high-quality services and leading industry products. With more than 28 years of industry experience, Digihua Intelligent can quickly and effectively assist customers in moving towards intelligent manufacturing.

1995

iMES Technology was established as a spin-off from the Industrial Technology Research Institute (ITRI), specializing in MES software research and development.

2000

Digiwin Software Investment established DigiChain Information, specializing in advanced scheduling system (APS) research and development.

2015

Digiwin Software invested in iMES Technology.

2018

iMES Technology and DigiChain Information merged to form Digihua Technology (Digihua Intelligent).

01

Digital solution provider for Intelligent factories

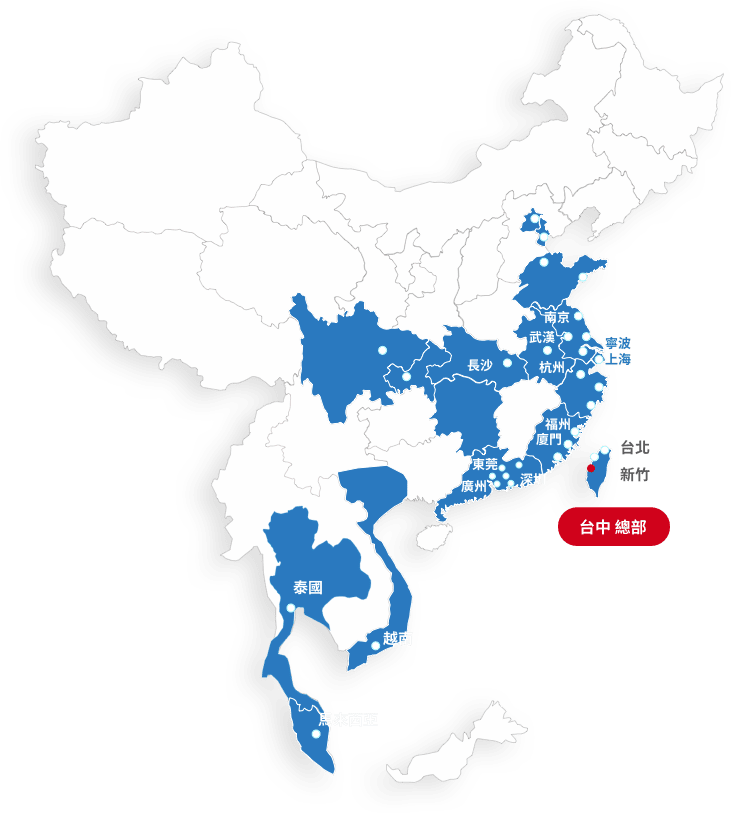

Digihua headquartered in Taichung with branches in Taipei, Hsinchu, and other locations in Taiwan.

With over 28 years of experience in intelligent manufacturing, Digihua focuses on developing industry-specific solutions and assisting customers in deepening their application of these solutions. Adhering to the philosophy of being where the customers are, Digihua has established over 36 service points across both sides of the Taiwan Strait, and continues to add new service locations to provide the most timely and localized service to its customers. With over 70% of its employees dedicated to research and development, Digihua aims to encapsulate its industry experience into industrial software through continuous innovation and R&D, offering its customers the most cutting-edge services and products.

The company business and service locations across both sides of the Taiwan Strait > 20

Continuously expanding its service network

Provide more localized and timely support to customers

Our team is dedicated to product development and technical services > 70%

Focus on industry-specific research and development

Provide our customers with professional industry-specific solutions

• Digihua Intelligent insists on intelligent manufacturing as its main direction, relying on advanced industrial software such as MES (Manufacturing Execution System), APS (Advanced Planning and Scheduling) and data services, to continuously provide customers in industries such as electronic semiconductors and discrete manufacturing with leading smart factory digital solutions.

• Digihua Intelligent’s digital software products, centered around the smart factory-related business scenarios and demands of the discrete manufacturing industry customer group in both Taiwan and Mainland China, integrate new-generation digital technologies such as big data, artificial intelligence, and the Internet of Things, helping customers achieve digital transformation.

02

Industry Focus

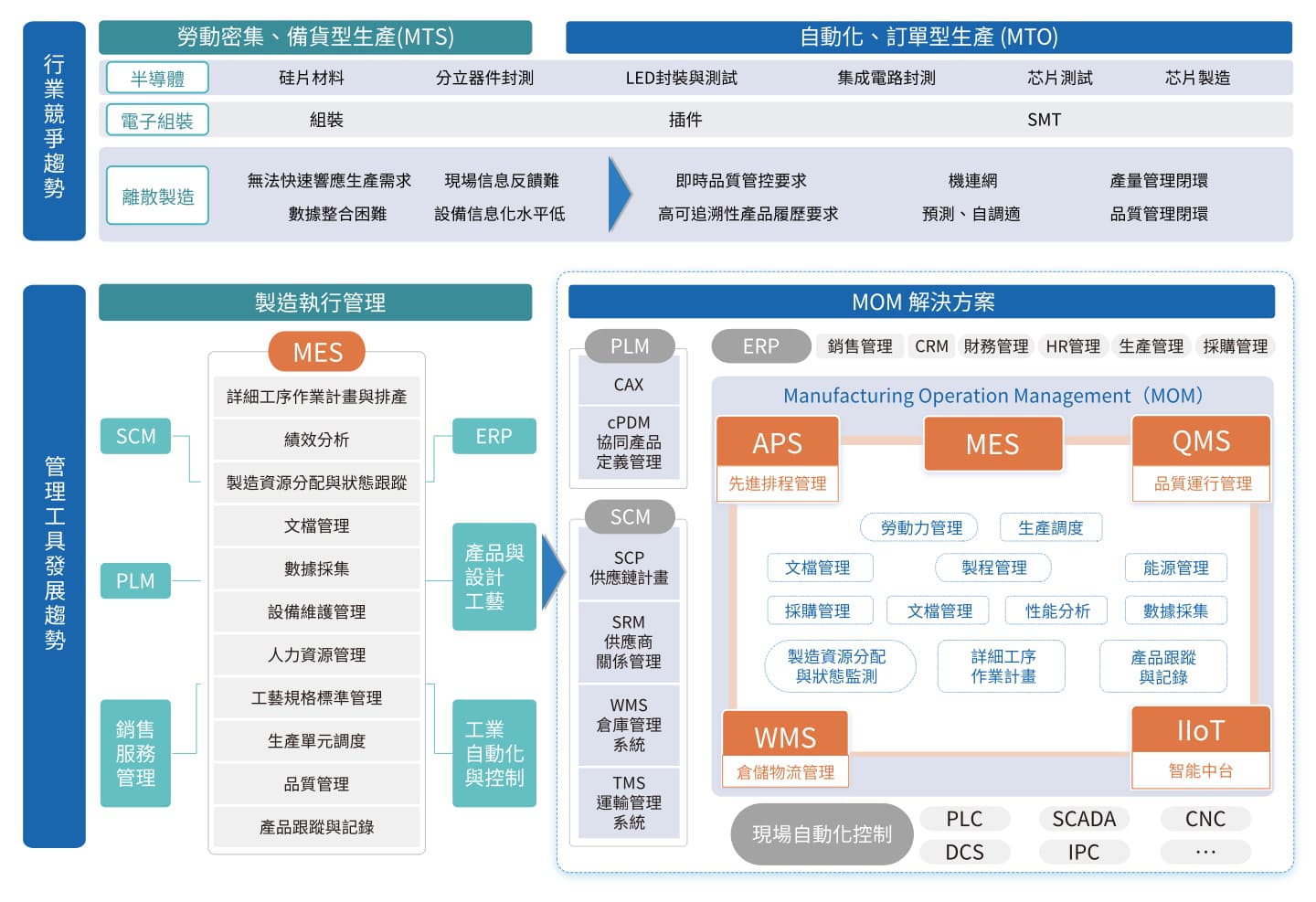

Developing MOM smart solutions to create digital value for customers

Digihua focuses on building a complete product line centered around the core execution platform of the intelligent factory, covering from the edge layer of local devices to the data collaboration layer of the cloud, and constructing differentiated competitive advantages.

The product line covers planning to execution, closely integrated with the characteristics of discrete manufacturing processes, and provides a comprehensive MOM solution with MES (Manufacturing Execution System) and APS (Advanced Planning and Scheduling System) as the core.

Semiconductor

- 合晶科技

- 中美矽晶

- 力成科技

- 矽格

- 京元電子

- 精材科技

Discrete Manufacturing

- 伯鑫

- 旭東機械

- 一原金屬

- 日揚科技

- 台灣油研

- 聖傑

- 一詮精密

Electronic Assembly

- 中磊電子

- 明基材

- 智邦科技

- 博泰車聯網

- 無錫上能

PCB

- 臻鼎科技

- 欣興電子

- 嘉聯益

- 中華精測

- 雍智科技

03

Creating Digital Value

Connecting Data and Collaborating

The smart factory solution supports the integration of all production elements, including man, machine, materials, methods, and measurements, to eliminate data silos and achieve digital transformation and intelligence, creating a lean and smart factory.