sAPS Smart Advanced Planning and Scheduling

Management System

Advanced Planning and Scheduling System

With the changes in the external market environment, low demand visibility and frequent order changes have become the norm, and large-scale small-batch manufacturing has become a prominent feature. Effectively arranging resources to meet customer’s increasingly strict delivery requirements has become a key factor in the success or failure of enterprises.

In response to the Industry 4.0 trend, highly accurate real-time information is needed to solve the production-sales mismatch caused by the past disconnect between demand planning and production execution. This has resulted in issues such as large discrepancies between estimated and actual production capacity, unreasonable demand and planning allocation, and lack of coordination between planning and execution processes. Through analysis, monitoring, and tracing through the system, the order scheduling can be highly flexible and intelligent.

Management Challenges

Business challenge: Unable to respond quickly to order lead times

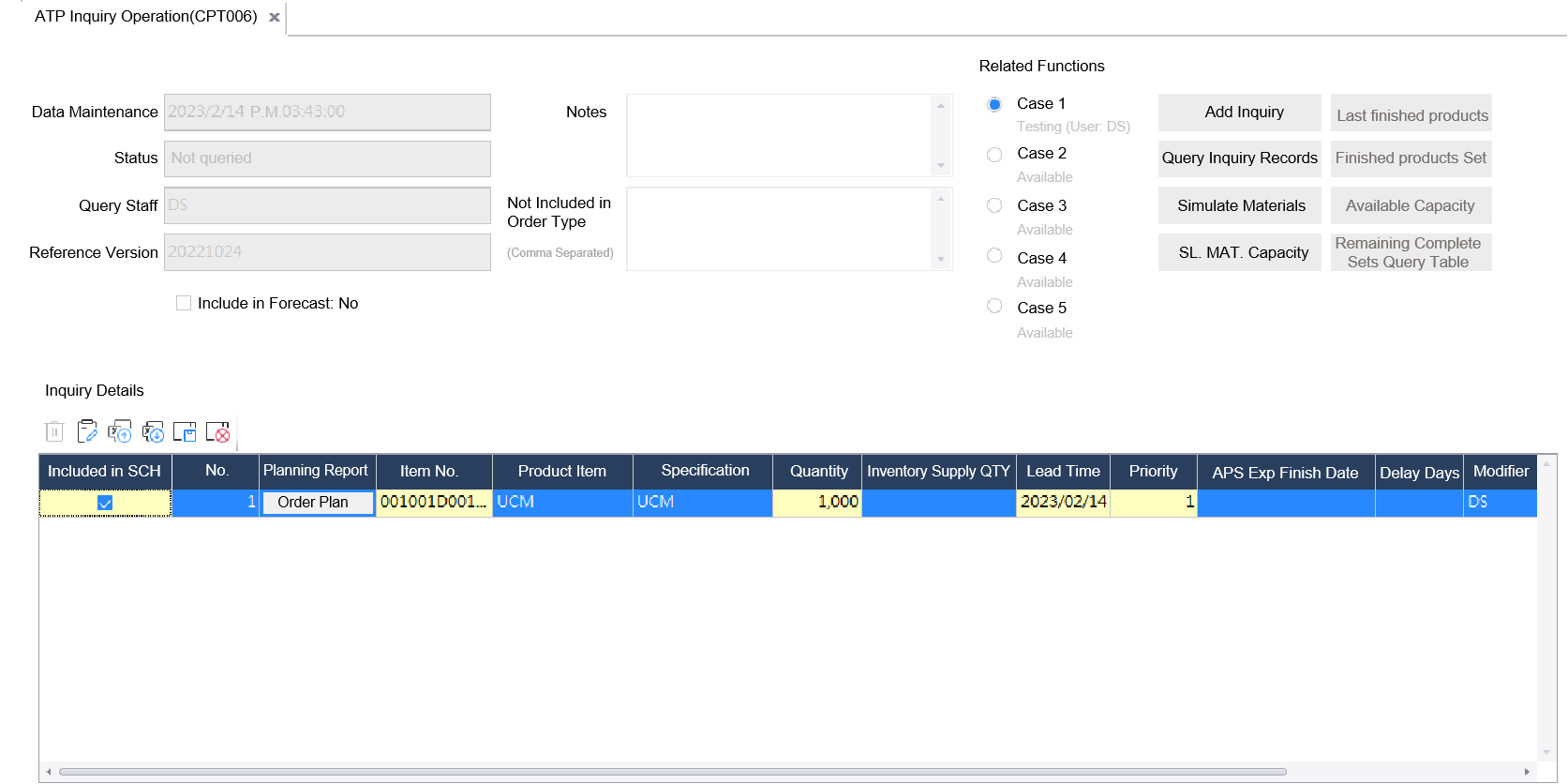

Promising delivery dates to customers but failing to meet them can result in customer complaints and impact future business opportunities. Inability to quickly respond to order lead times can lead to lost potential business. Additionally, there is a lack of visibility into the production schedule and progress of customer orders.

Manufacturing Floor Supervisor: Production Plan Not Matching Reality

The production manager issues production tasks for the next few days, and the floor supervisor is responsible for arranging which equipment will be used for production. However, the supervisor often encounters situations where work orders are incomplete, new orders are inserted, or pre-scheduled orders exceed the current production capacity. As a result, progress on the floor does not accurately reflect the production plan, and updates are not properly reported back to the production manager.

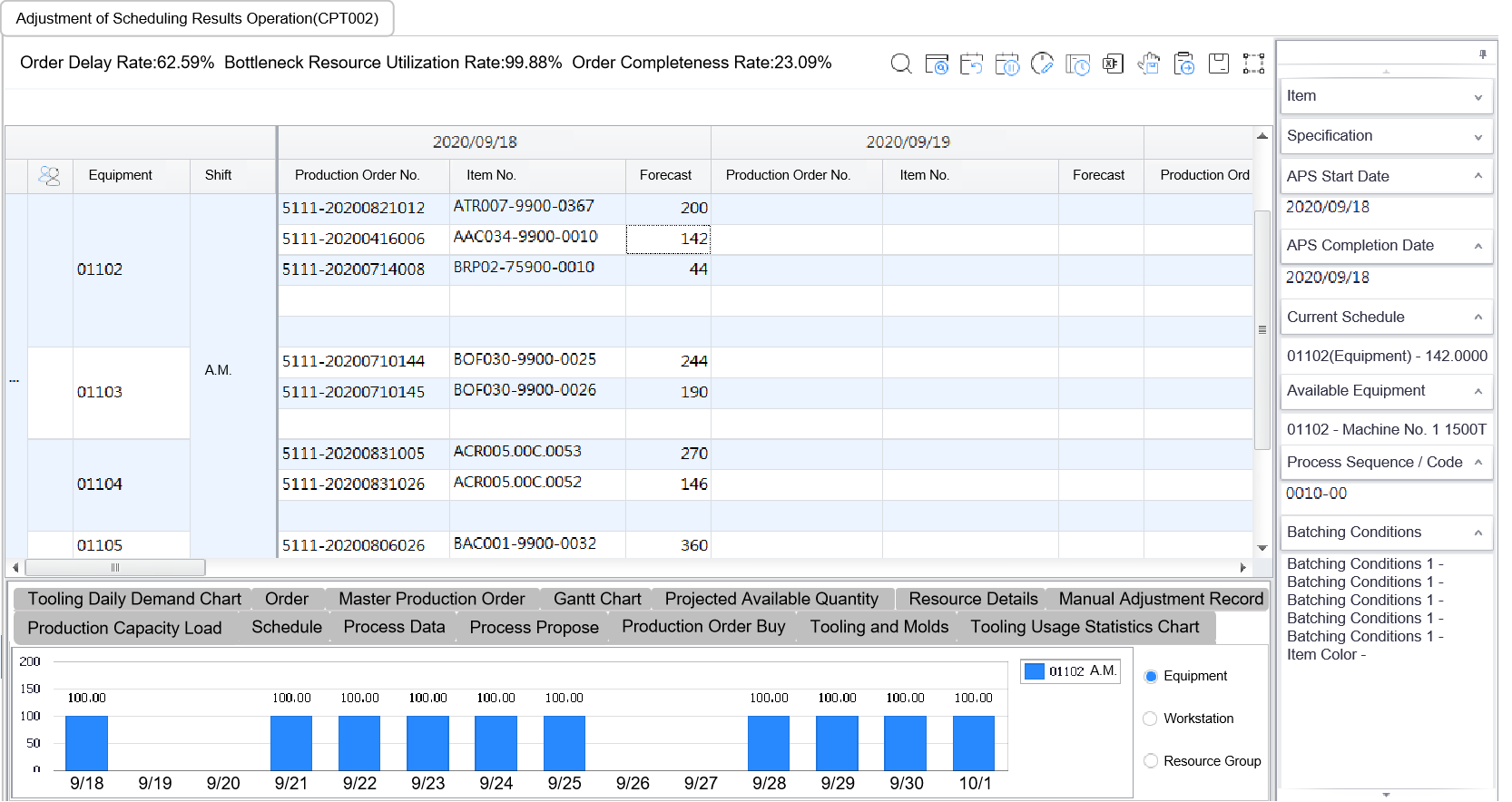

Production control: Discrepancy between plan and reality affects delivery

Production control often deals with frequent order changes, material supply uncertainty, and other situations that require frequent adjustments to production scheduling and cross-departmental coordination. Production control must coordinate with sales to negotiate delivery dates, collaborate with procurement to ensure timely material supply, and work with the manufacturing site to monitor the status of equipment, tools, molds, and personnel. These factors all contribute to the potential discrepancy between the production plan and reality, which may ultimately impact delivery.

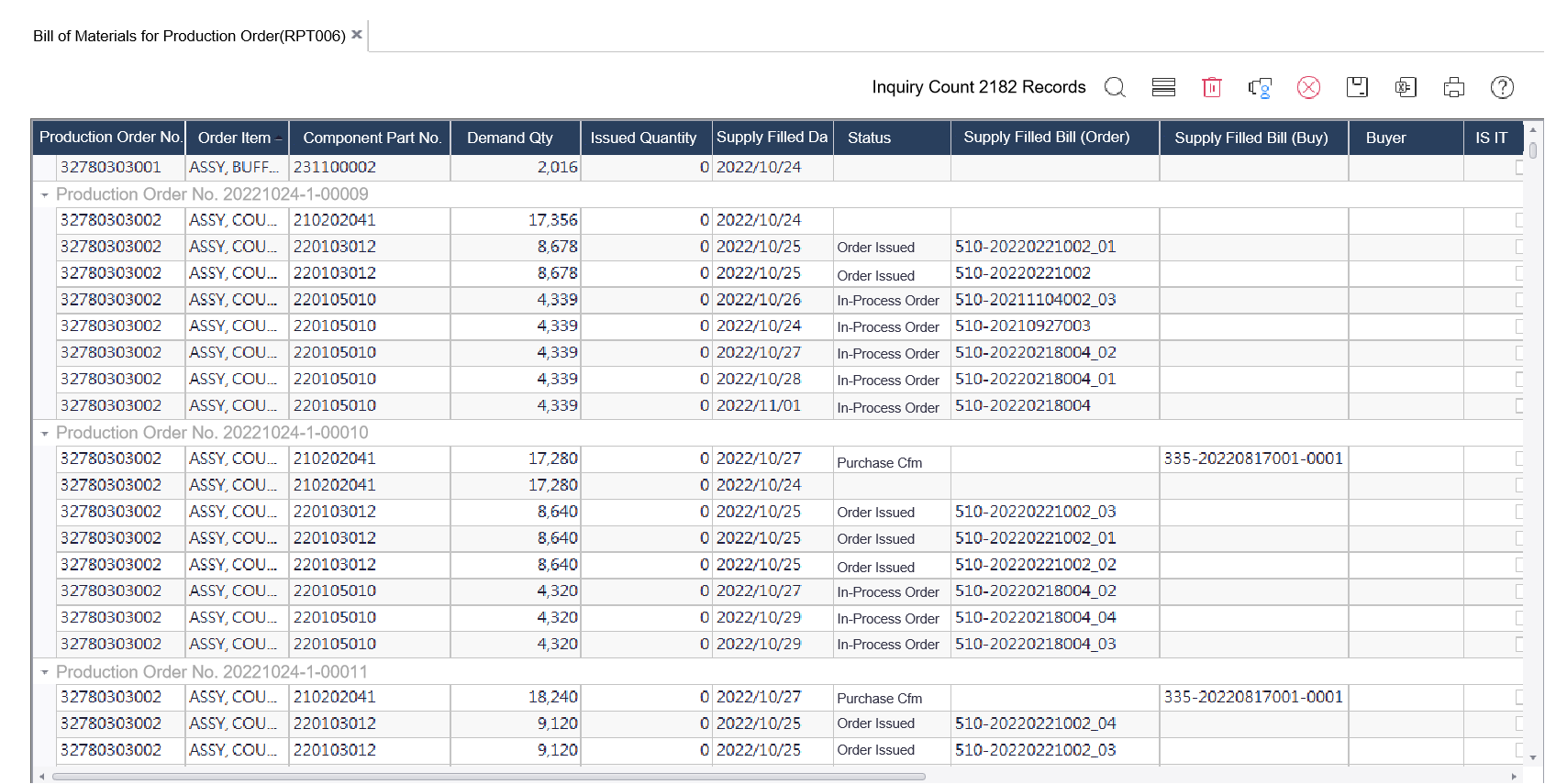

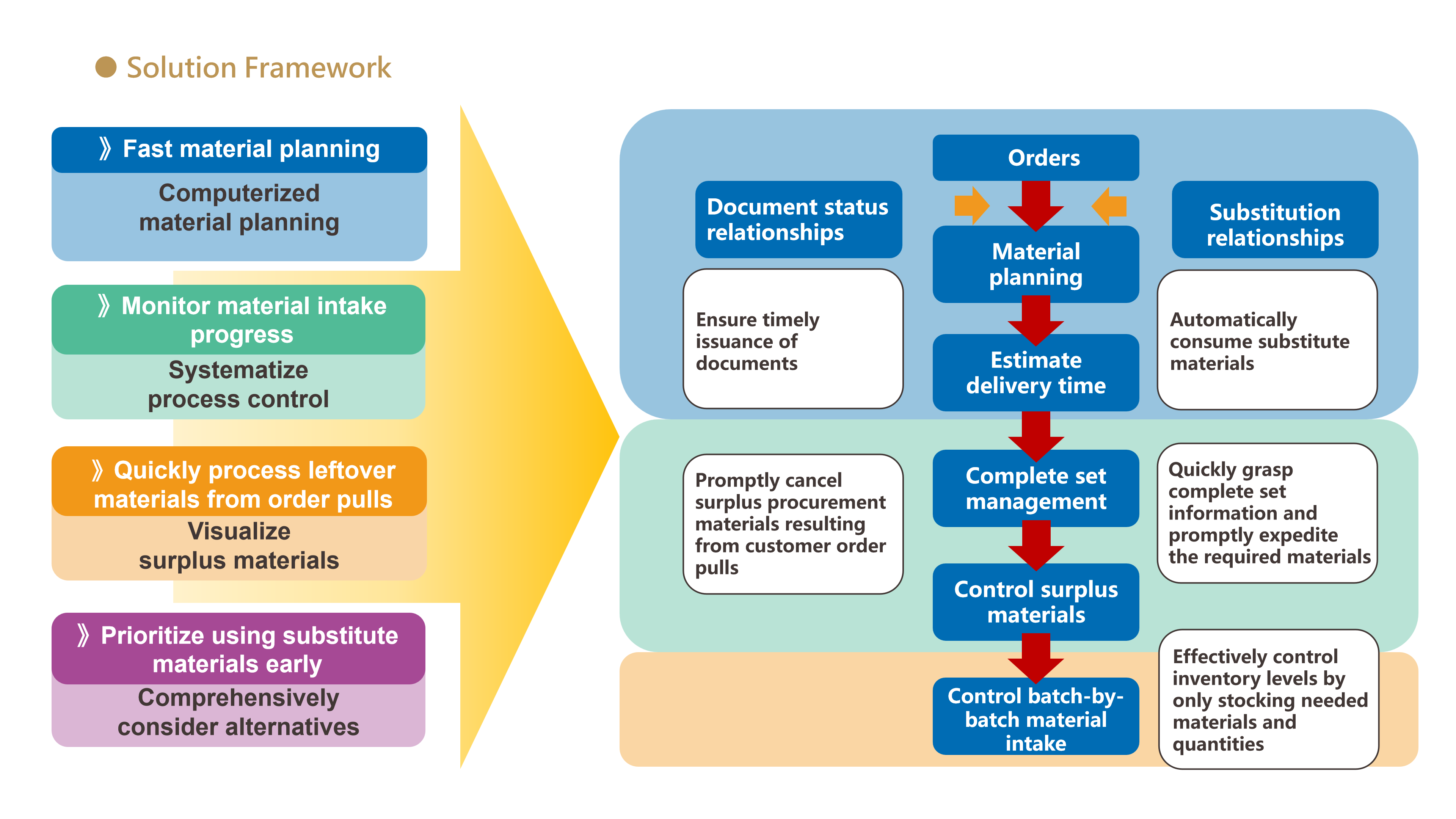

Materials control & procurement: Low rate of complete materials for work orders, frequent material expediting

With MRP adopting infinite capacity and only determining expected material receiving schedule through lead time, it may lead to a low rate of complete materials for work orders and frequent material expediting. However, with sAPS, the production plan can be arranged based on the expected time of arrival of critical materials, and the delivery schedule for non-critical materials can be scheduled based on the expected start date.

sAPS Product Core Functions

One-click completion

Quickly complete the overall factory plan for production, procurement, shipping, and machine arrangement.

Closely integrated with MES, supporting rolling scheduling

Automatically adjust scheduling quantities based on feedback from the production site, giving priority to work orders that are behind schedule and automatically deferring subsequent scheduling. In the event of a smooth production situation, subsequent scheduling is automatically started earlier.

Optimization rules can be configured

Enterprises can configure multiple rule types into a scheduling model to meet business needs in different industries and scenarios.

Scheduling algorithms for different scenarios

Forward scheduling based on material arrival time, backward scheduling based on delivery date, and forward or backward scheduling based on bottleneck.

Avoid changes in plan quality due to personnel changes

Extract abstract scheduling rules based on industry characteristics, reduce reliance on senior personnel, and not lower the quality of plans due to personnel changes.

Provide order configuration relationships

Sales or production management can trace back from orders to delayed work orders and purchase orders, and materials management can trace back from delayed purchase orders to affected orders.

Graphical and visualized

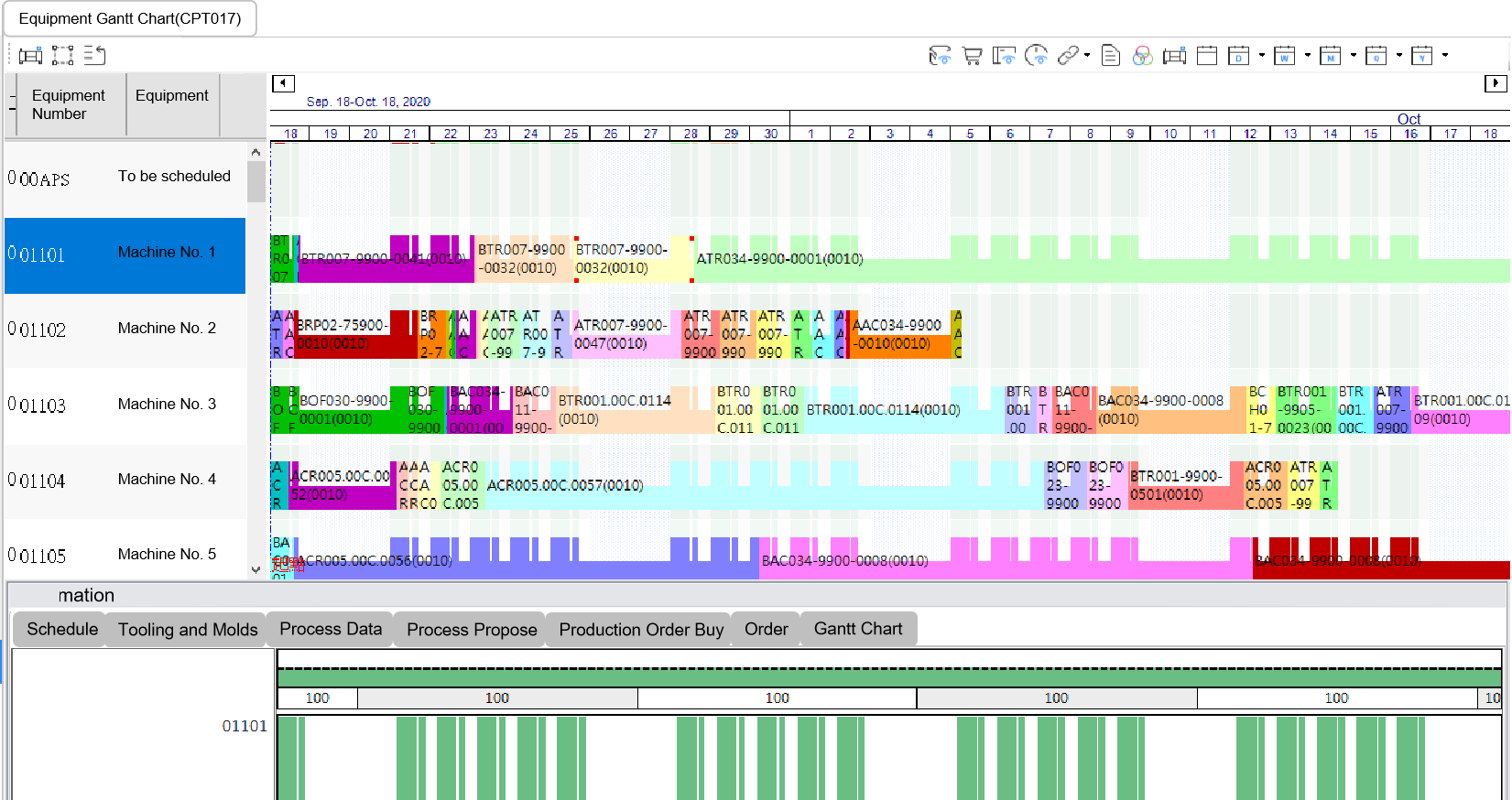

Friendly graphical interface provides a visualized experience, and users can quickly query, analyze, and adjust scheduling results.

sAPS Application Case Studies

sAPS Partial Case Clients - China

In a scenario where revenue continues to rise and delivery cycles are halved, utilizing the sAPS system enables enterprises to possess rapid response capabilities when facing urgent order adjustments. Simultaneously, it enhances the efficiency and accuracy of enterprise production planning, while addressing internal issues such as machine management, mold management, process management, and procurement management. This continuous improvement allows enterprises to enhance their competitiveness.

The implementation of sAPS has driven innovation in company management, achieving a higher level of production planning and scheduling. Leveraging the system’s rapid and automated optimization capabilities, the production plan is formulated considering various constraints such as personnel, equipment, and materials. This enables quick adaptation to changes and meets customer delivery requirements.

In the face of the rigorous challenges in the PCB industry, the implementation of an intelligent scheduling system has enabled automated scheduling. Coupled with real-time and automatic report generation, this has significantly improved timeliness and accuracy, enhancing production scheduling and monitoring capabilities, as well as production and sales efficiency. It addresses issues related to ‘supply and demand management with rapid response to delivery times’ and the coordination problems of ‘material feeding schedules and on-site dispatch plans’.

sAPS Partial Case Clients - Taiwan

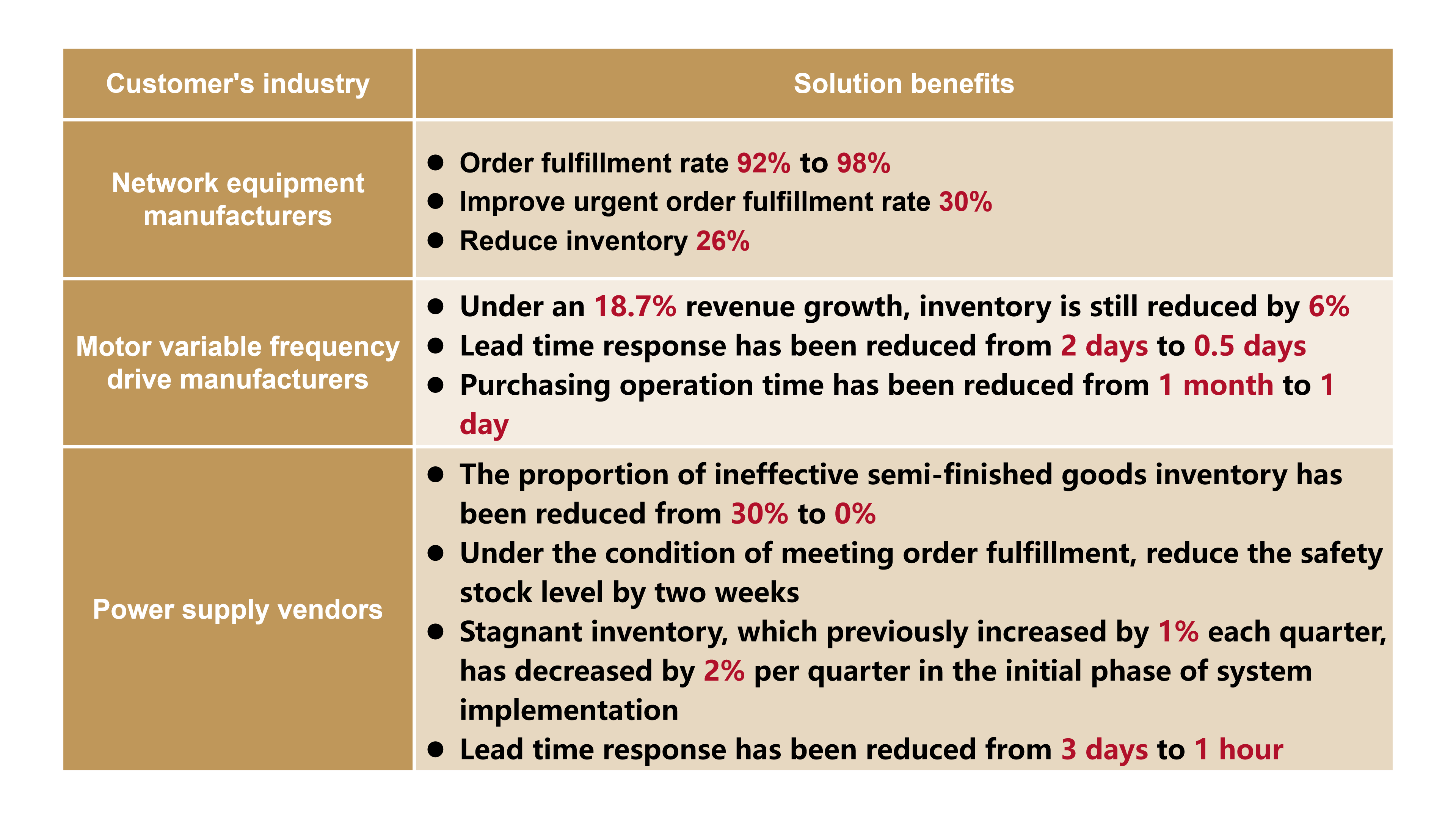

In the context of a complex environment with small quantities, diverse materials, and numerous substitutes, considering flexible material preparation logic becomes crucial. This addresses the shortcomings of the existing MRP, reducing material preparation calculation time by half, improving material procurement accuracy, and subsequently reducing inventory turnover days. This leads to an increase in order fulfillment rates.

In the face of a rapidly changing environment with a large volume of materials, particularly in the electronics industry where materials are shared between two manufacturing sites, material management becomes more complex and manual calculations are time-consuming. The implementation of sAPS not only shortens the schedule for personnel to calculate material shortages but also enhances precise material control, leading to an improvement in on-time delivery rates for production schedules. Simultaneously managing sufficient materials reduces equipment changeover frequency, increases equipment utilization rates, and effectively enhances overall delivery capabilities.

By employing a continuous batch production model, waste from changeovers and line stops is minimized, resulting in increased production efficiency. This breakthrough addresses the production bottleneck of low batch sizes and high frequencies, reducing production costs and enhancing effective output diversification. Achieving high service level requirements in the components industry emphasizes the importance of supplying a diverse range over a large quantity, a key objective in this context.