iMES intelligent manufacturing

Execution System

Expert in integrated management solutions for smart manufacturing

It provides production management solutions for the manufacturing supply chain of semiconductor industry, including silicon wafer materials, epitaxy, chip manufacturing, packaging, and testing. Its solutions cover manufacturing execution systems, equipment integration, inspection data collection, parameter management, production control, quality management, and a command center for production management. With a professional consulting service team, an integrated system covering upstream, midstream, and downstream of the semiconductor industry, implementation experience, and a flexible system architecture, iMES works with customers to create management benefits and data value. It effectively improves factory operation efficiency, shortens lead times, reduces costs, implements real-time production control, reduces operational risks through intelligent early warnings, improves product quality, enhances customer satisfaction, optimizes enterprise competitiveness, and connects upstream and downstream industries and integrated foundations.

iMES Product Core functions

iMES Five central capabilities that strengthen process control management

iMES can vertically integrate with ERP and equipment layers, and through its five central capabilities, it can effectively trace the production history of chips, real-time quality statistics, quality control rules, and equipment utilization rate analysis.

Wafer Receiving Center

Provides fast and flexible tracing of wafer history and incoming material history. Through customized information collection and automatic file conversion, it effectively records incoming wafer information and manages wafer inventory.

The Production Dispatch Center

The Production Dispatch Center provides customizable rules for selecting chips and setting up process card formats, and effectively manages the issuance of production chips and materials. When opening production batches and printing process cards, it can effectively record incoming material traceability information.

The Production Operation Center

The Production Operation Center provides real-time and complete visibility for personnel to view standard parameters, available equipment, and provide feedback on customized data collection projects within the manufacturing process. For the epitaxial process, it offers effective collection of corresponding wafer numbers, ring cycles, locations, and substrate information, and verifies wafer selection and processing procedures prior to chip manufacturing.

The Quality Control Center

The Quality Control Center provides real-time collection of testing data for various types of inspection stations during the production process, and conducts statistical process analysis on the data in real-time. It determines whether there is a violation of the customized quality rules based on the test results and automatically initiates the abnormal processing flow.

The Equipment Automation Center

The Equipment Automation Center provides semiconductor equipment with standard integration interfaces such as EAP platform, inspection equipment, OPC, document transmission interpretation, etc., to provide customers with fast and effective acquisition of equipment status, production data, processing program number download, inspection program number download, automatic entry and exit station and other standard applications.

iMES Product Features

Work in Process (WIP, WIP Tracking)

The WIP (Work in Process) tracking module for process control is one of the most critical production management mechanisms in the iMES integrated solution. Its main purpose is to control the production process, equipment, and process parameters for on-site work orders, production batches, box or chip numbers, and track the production process to ensure that on-site data can be recorded in real-time and accurately. It provides accurate and real-time production information for on-site supervisors and business units, enabling accurate and fast on-site and business decision-making.

Detailed manufacturing scenario modeling

Using a graphical interface to fully and accurately describe the physical layout of the site and to construct complex and varied production process situations; providing diversified enterprise rules and programmable logic parameter extraction boxes based on the industry, allowing for rapid and flexible construction of process tracking and control modes.

Complete Manufacturing Resource Management

For the resources utilized during the manufacturing process, such as personnel, raw materials, equipment, and components, iMES provides comprehensive management to regulate their usage, track their utilization, and trace their results.

Rigorous Process Parameter Management

Flexible and rigorous setup, modification, calculation, collection, and control of operation characteristics, whether they are quantifiable physical characteristics (e.g. baking temperature) or management characteristics (e.g. standard yield, aging), for each process station.

Control of manufacturing conditions based on formulas.

Real-time manufacturing process control through user-defined control logic, providing flexible and immediate process analysis and control for each production batch or chip on the manufacturing floor. It can be set up to trigger various corresponding actions such as abnormality alerts, production pause, and warnings based on user needs.

Real-time production data collection

Flexible and real-time online data collection and process control can be achieved through a variety of front-end data collection interfaces, such as PCs, tablets, and PDAs. At the same time, it provides the ability to handle batch processing, merging, rework, skipping stations, skipping processes, and temporary outsourcing, and provides authorized users with the ability to execute an “undo” function that is not restricted by the number of stations.

Complete data inquiry and reporting

Real-time data inquiry, in-and-out station reports, production reports, process statistical reports and other functions, can be queried at any time inside or outside the factory.

Multi-layer quality analysis

Provides multi-layer statistical analysis, including inspection batch quality status inquiry, control chart analysis, statistical reports, and control chart browsing functions. Provides quality control, engineering, and manufacturing as the basis for setting process capability and product quality objectives, abnormality handling, or process improvement.

Equipment networking

Supports the networking of various testing equipment such as RS232, GPIB, TCP/IP, PLC, SECS. Through flexible client networking settings and programmable management methods with driver programs, it provides online inspectors with a fast and convenient way to input testing results from the equipment through networking.

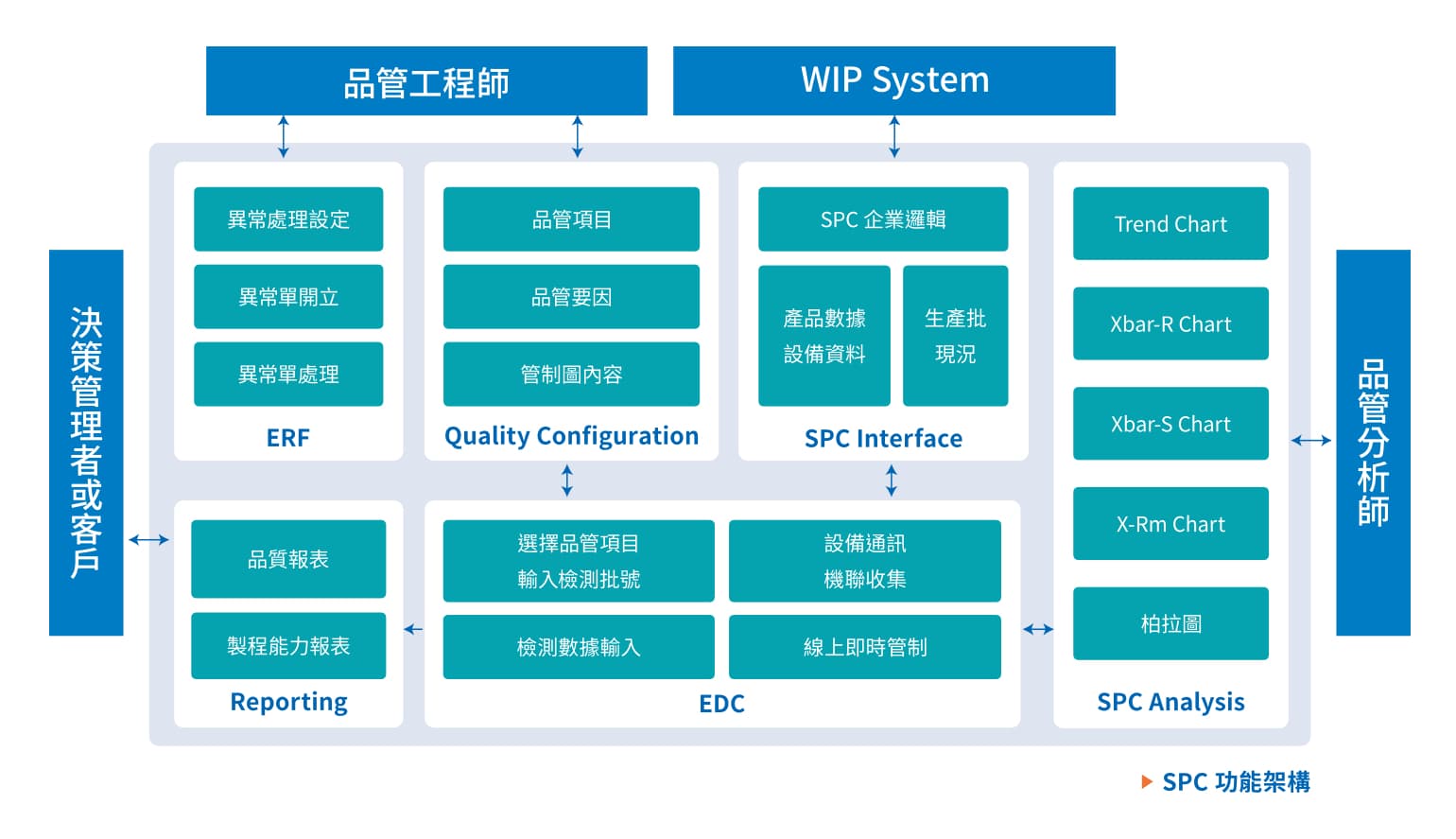

Quality control solution in iMES (SPC, Statistic Process Control)

The SPC system is the quality control solution in iMES. By collecting real-time quality information such as counts or measurements during the production process and using statistical control methods to set warning and control rules, abnormal or trending processes can be detected in real-time, and improvement actions can be taken immediately to quickly restore normal processes and reduce product defect rates.

Parameterized quality control project settings.

Parameterized quality control project setting allows users to customize multiple measurement or count quality control projects according to actual needs. Different control charts can be used for control based on the quality control projects settings. The system can also automatically compose and draw various control charts based on the flexible control reasons/levels set by users.

User-defined control methods

The system allows for the customization of control specifications and rules based on quality control items and their set control factors/layers. This provides the flexibility for the vendor to define control specifications and methods that suit their specific needs. The system also allows for the flexible assignment of the corresponding handling methods when there are violations of the control rules during online control and analysis.

Multiple Data Collection Methods

The system provides data collection for both count and measurement quality data, with three collection methods: equipment interface, manual input, and file conversion. During the inspection process, the system actively obtains production data and control settings with inspection samples, displaying appropriate input interfaces and providing the system with various data collection methods.

Multilevel Quality Analysis

Multi-level quality analysis is provided, including the analysis of quality status of inspection batches, various related control charts, statistical reports, control chart review, and other functions. Through various statistical analysis results, relevant control settings can be adjusted, serving as a basis for setting process capabilities and product quality goals, handling abnormal reasons, or improving processes.

Equipment Networking

Supports the networking of various testing equipment such as RS232, TCP/IP, PLC, SECS, GPIB, etc. Through flexible client-side networking settings and programmable management methods for driver software, it provides online quality inspection personnel with quick and convenient networking input of testing results from inspection equipment.

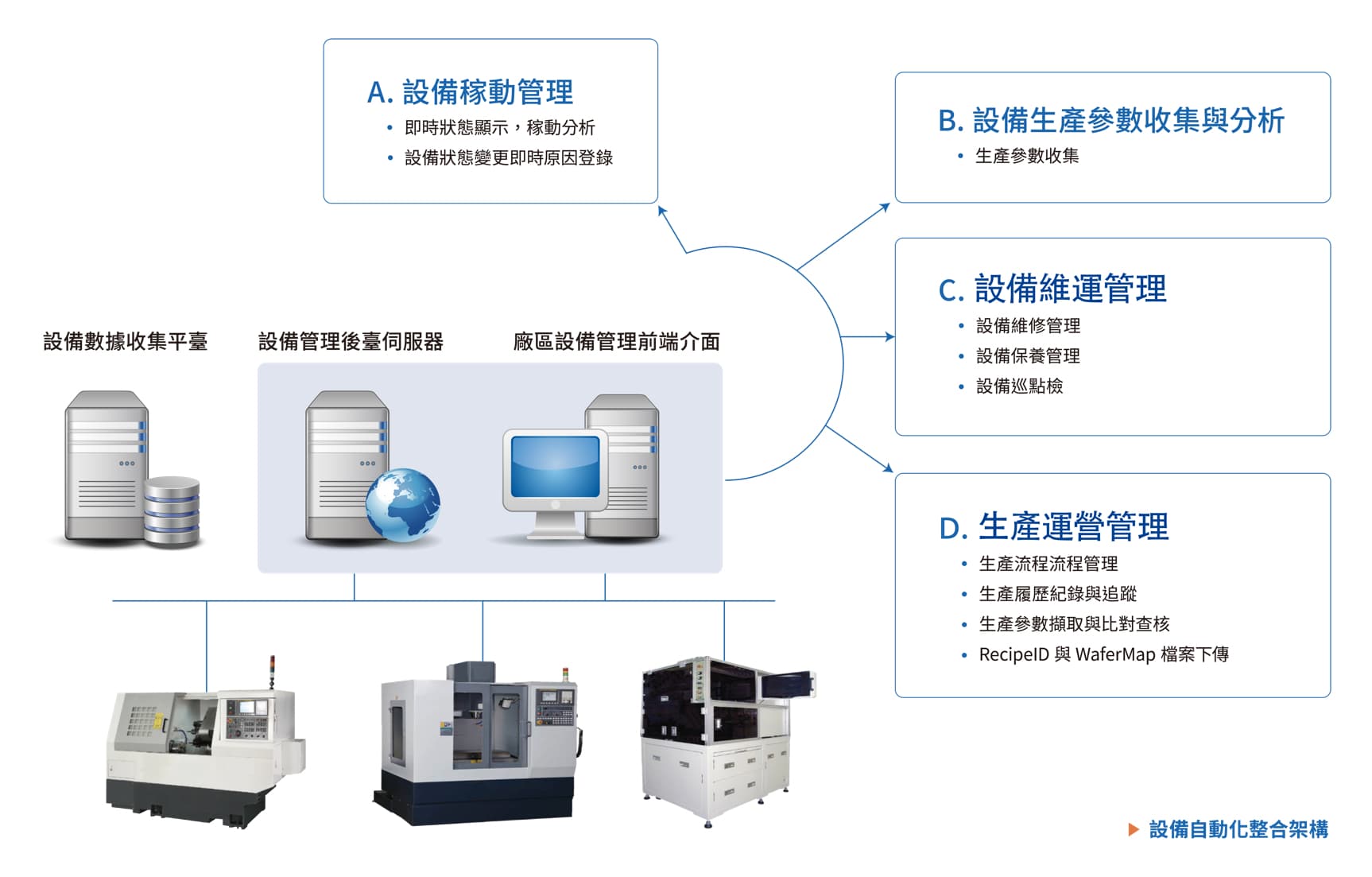

Equipment Management (EMS) and Preventive Maintenance (EPM)

Equipment Management System (EMS) and Equipment Preventive Maintenance (EPM) are important for semiconductor and chip manufacturing industries due to the large variety and quantity of production equipment. Effective tracking and management of equipment status are crucial for mastering on-site equipment, improving equipment utilization, and performing maintenance and preventive measures. These are all important factors for increasing equipment uptime, enhancing production capacity, and reducing cycle time in the manufacturing process.

Real-time equipment status monitoring

The EMS system provides flexible equipment status transition settings, and through the monitoring interface provided by the system, management personnel can easily monitor the operation of all on-site equipment at a glance.

Equipment Integration

Based on the automation capabilities of the equipment, we provide automated equipment integration solutions planning. Through standard integration interfaces such as EAP platform, inspection equipment, OPC, document transfer interpretation, etc., we provide fast and effective retrieval of equipment status, acquisition of production data, processing program, test program number downloads, and other application planning.

Flexible maintenance projects and frequency settings

The EPM system provides real-time fault notification through its equipment failure reporting function and also provides maintenance resource management. The EPM system formulates the entire maintenance plan using various modes such as scheduled, quantitative, and on-demand maintenance.