Electronic Assembly Network Communication

Industry Solution

Challenges in Industry Management

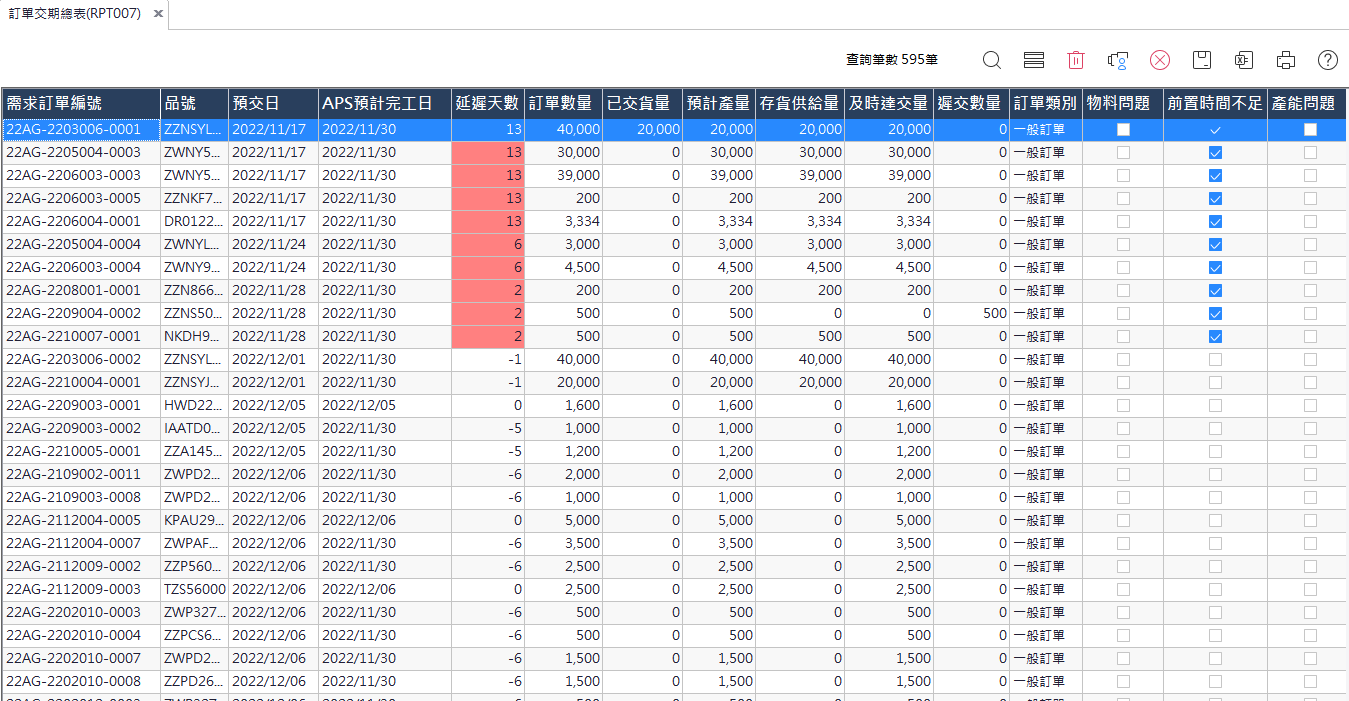

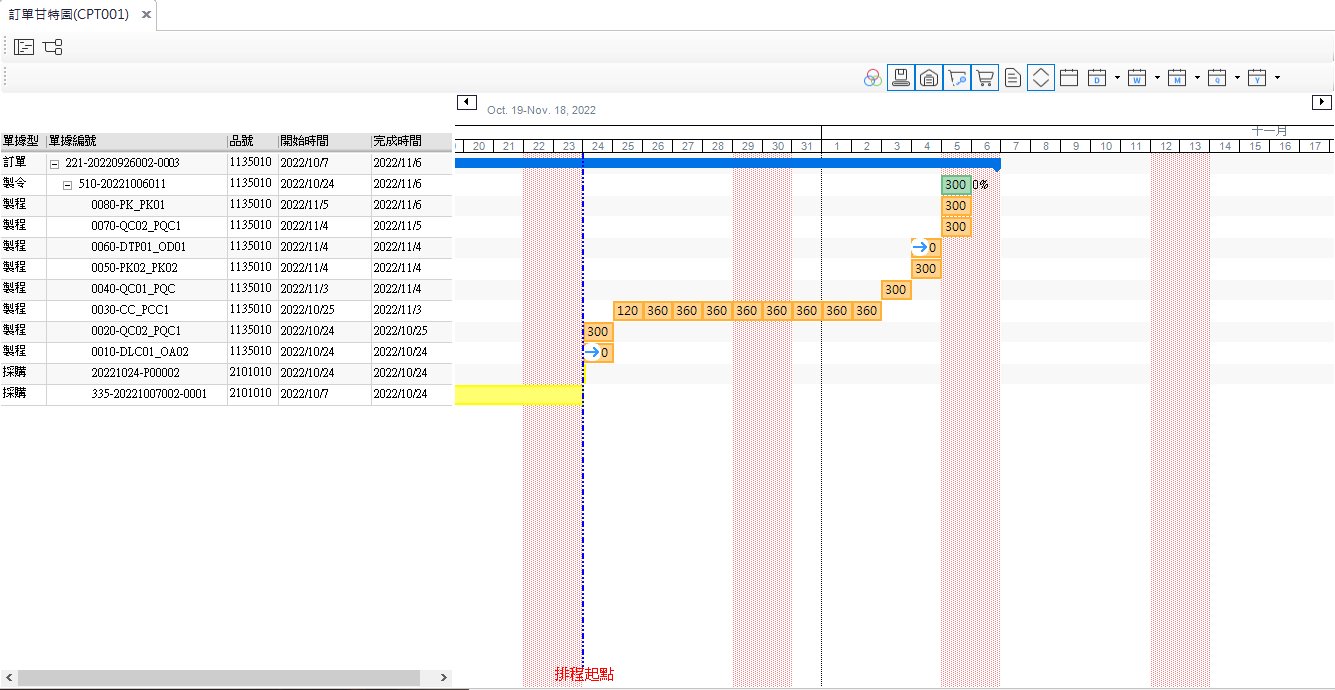

- Frequent order changes leading to frequent adjustments of production scheduling, resulting in high costs of human resources and materials.

- Short product life cycles leading to frequent version updates and ECN changes, making product data management difficult.

- Complex material and product structures and complex substitute material relationships, making it difficult to arrange the optimal production plan.

- Batch delivery of purchased materials, making production pace and scheduling difficult.

- Production modes include both in-house and outsourcing, and production capacity scheduling relies on personnel experience, resulting in difficulties in informatization.

- Frequent urgent customer demands leading to high inventory costs.

- Inability to respond to customer order demands quickly, resulting in order losses.

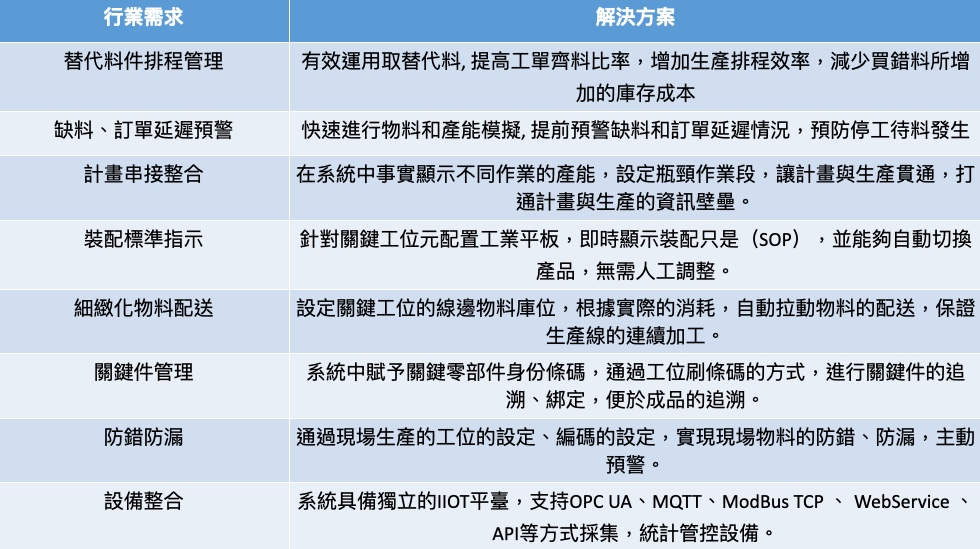

Solution implementation benefits

Manager

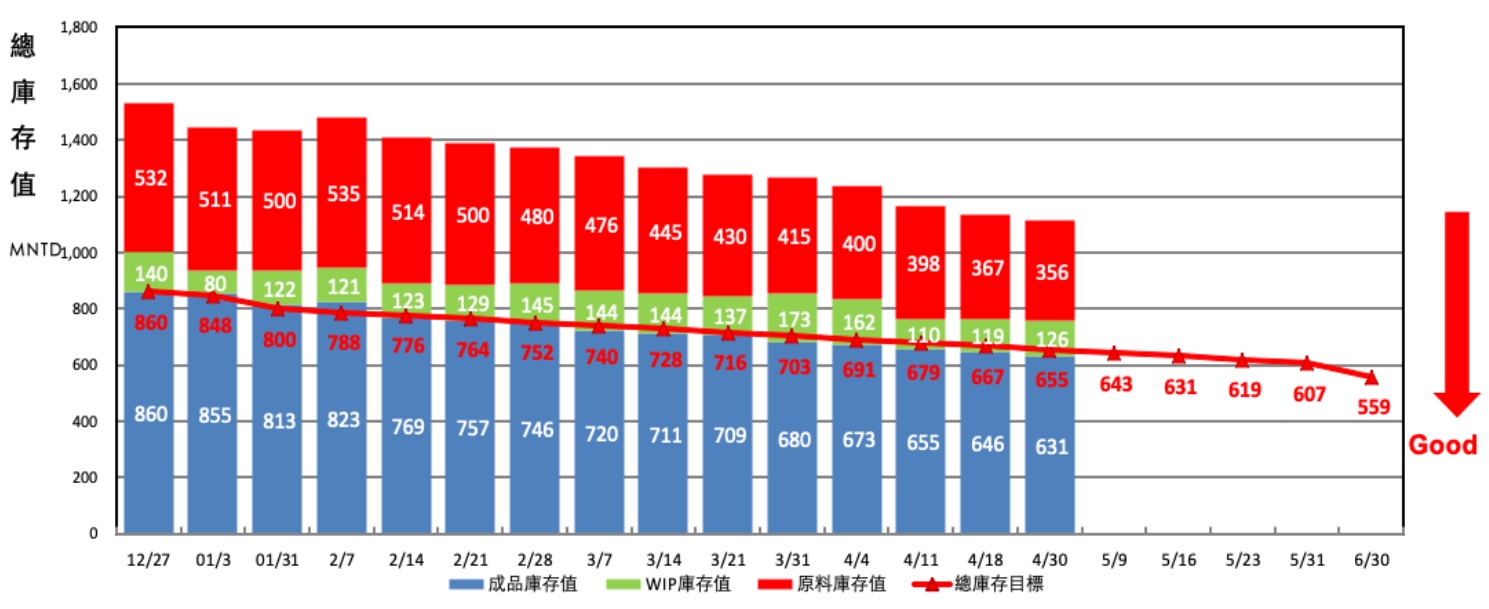

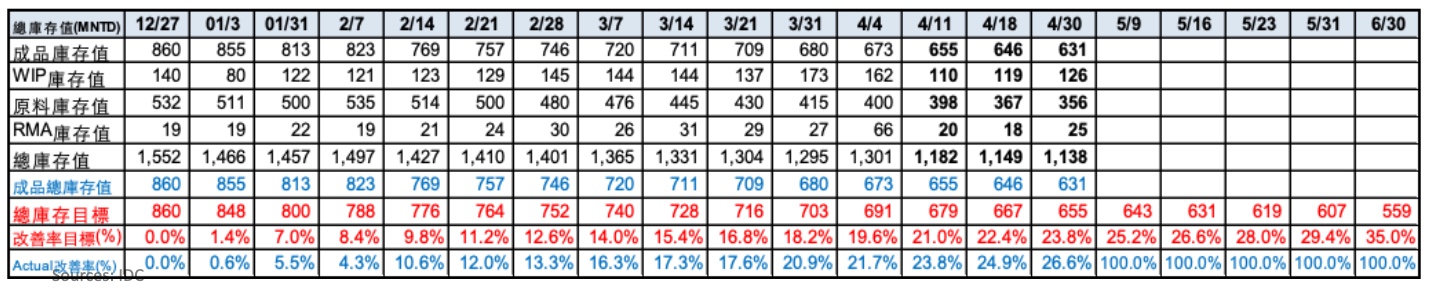

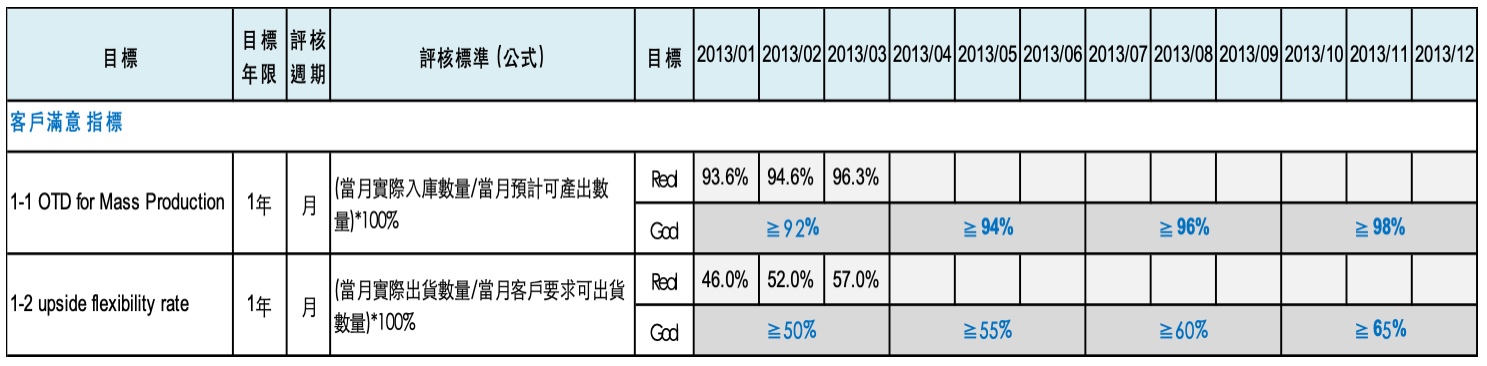

Customer performance achievement

Monthly optimistic/pessimistic performance

Quantity that can be promised for delivery

PP

Assist in monthly scheduling priority

Provide business order suggestion

Quickly respond to order changes

PC

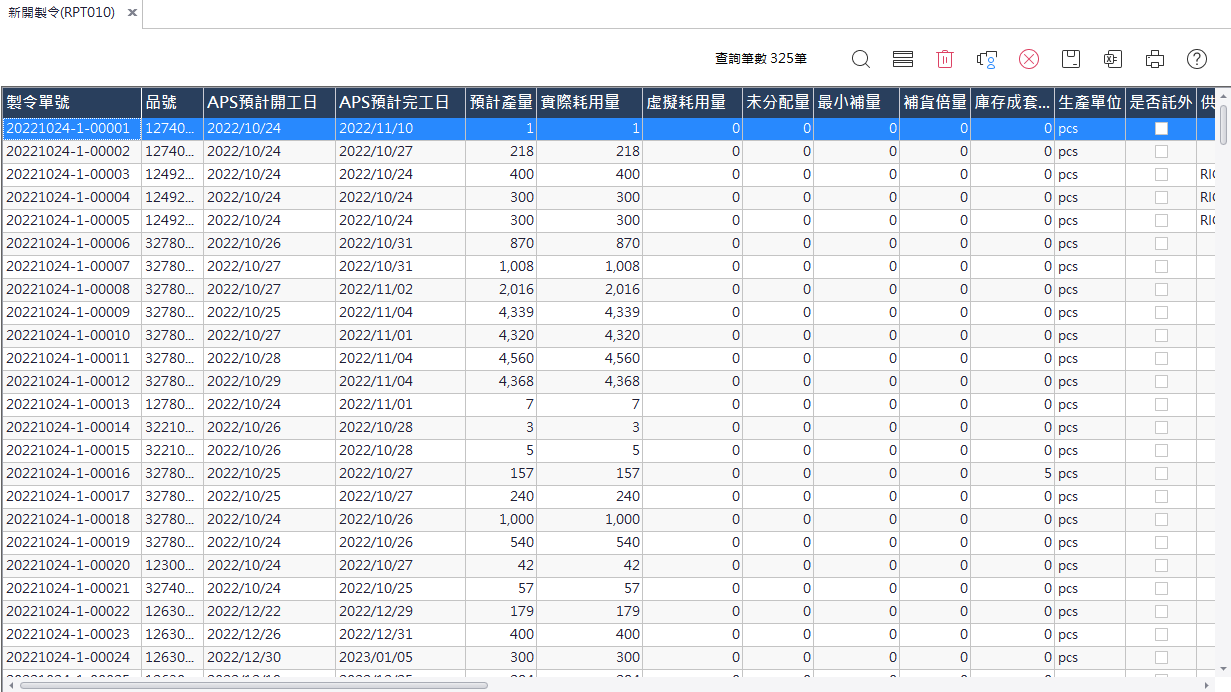

Check material availability and lead time for work orders

Quickly identify material shortages by part number

Ensure correct materials are pulled in for production

Purchasing

Trace the real material demand

Reduce the quantity of material inventory